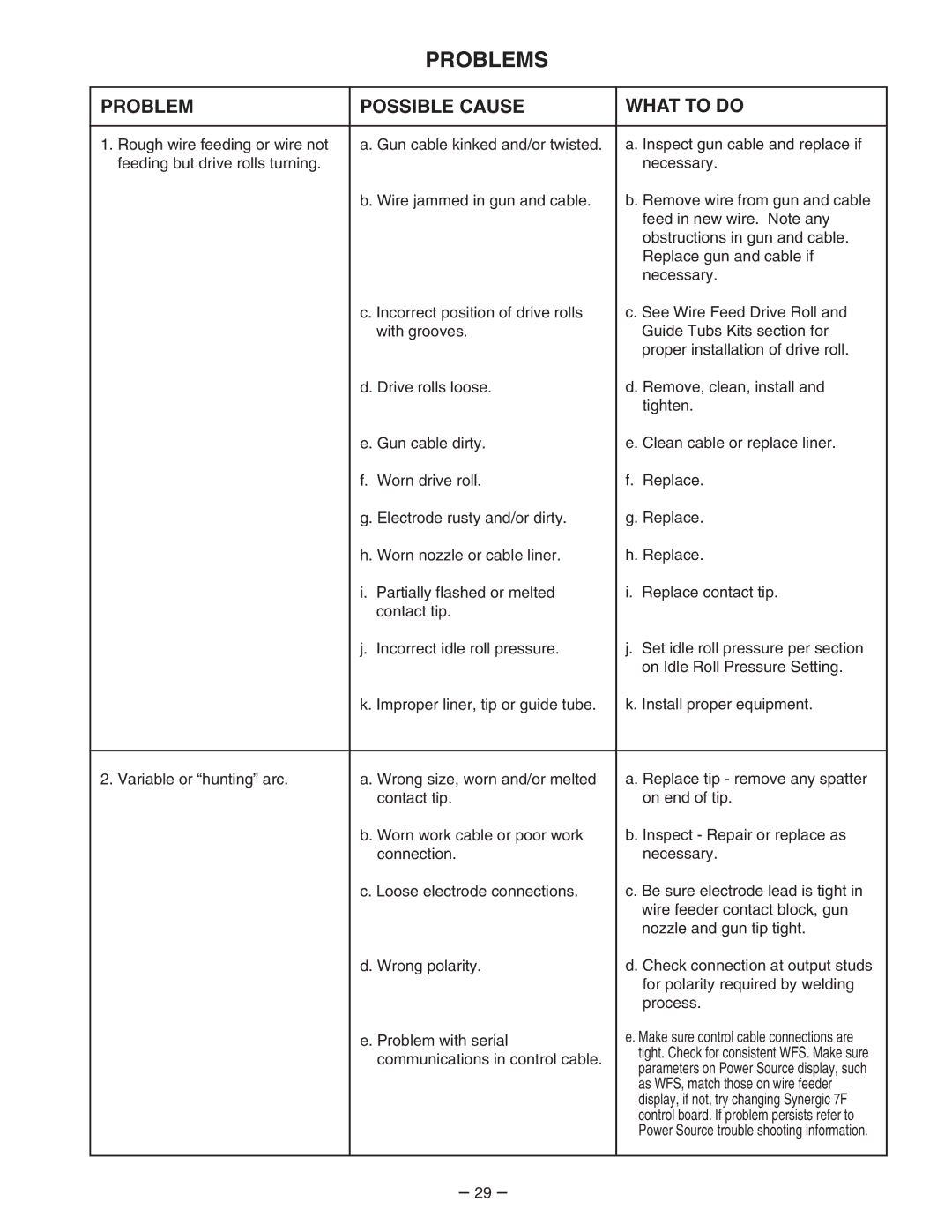

PROBLEMS

|

|

|

|

|

|

|

|

|

| PROBLEM |

|

| POSSIBLE CAUSE |

|

| WHAT TO DO |

|

|

|

|

|

|

|

|

|

|

| 1. Rough wire feeding or wire not |

|

| a. Gun cable kinked and/or twisted. |

|

| a. Inspect gun cable and replace if |

|

| feeding but drive rolls turning. |

|

|

|

|

| necessary. |

|

|

|

|

| b. Wire jammed in gun and cable. |

|

| b. Remove wire from gun and cable |

|

|

|

|

|

|

|

| feed in new wire. Note any |

|

|

|

|

|

|

|

| obstructions in gun and cable. |

|

|

|

|

|

|

|

| Replace gun and cable if |

|

|

|

|

|

|

|

| necessary. |

|

|

|

|

| c. Incorrect position of drive rolls |

|

| c. See Wire Feed Drive Roll and |

|

|

|

|

| with grooves. |

|

| Guide Tubs Kits section for |

|

|

|

|

|

|

|

| proper installation of drive roll. |

|

|

|

|

| d. Drive rolls loose. |

|

| d. Remove, clean, install and |

|

|

|

|

|

|

|

| tighten. |

|

|

|

|

| e. Gun cable dirty. |

|

| e. Clean cable or replace liner. |

|

|

|

|

| f. Worn drive roll. |

|

| f. Replace. |

|

|

|

|

| g. Electrode rusty and/or dirty. |

|

| g. Replace. |

|

|

|

|

| h. Worn nozzle or cable liner. |

|

| h. Replace. |

|

|

|

|

| i. Partially flashed or melted |

|

| i. Replace contact tip. |

|

|

|

|

| contact tip. |

|

|

|

|

|

|

|

| j. Incorrect idle roll pressure. |

|

| j. Set idle roll pressure per section |

|

|

|

|

|

|

|

| on Idle Roll Pressure Setting. |

|

|

|

|

| k. Improper liner, tip or guide tube. |

|

| k. Install proper equipment. |

|

|

|

|

|

|

|

|

|

|

| 2. Variable or “hunting” arc. |

|

| a. Wrong size, worn and/or melted |

|

| a. Replace tip - remove any spatter |

|

|

|

|

| contact tip. |

|

| on end of tip. |

|

|

|

|

| b. Worn work cable or poor work |

|

| b. Inspect - Repair or replace as |

|

|

|

|

| connection. |

|

| necessary. |

|

|

|

|

| c. Loose electrode connections. |

|

| c. Be sure electrode lead is tight in |

|

|

|

|

|

|

|

| wire feeder contact block, gun |

|

|

|

|

|

|

|

| nozzle and gun tip tight. |

|

|

|

|

| d. Wrong polarity. |

|

| d. Check connection at output studs |

|

|

|

|

|

|

|

| for polarity required by welding |

|

|

|

|

|

|

|

| process. |

|

|

|

|

| e. Problem with serial |

|

| e. Make sure control cable connections are |

|

|

|

|

| communications in control cable. |

|

| tight. Check for consistent WFS. Make sure |

|

|

|

|

|

|

| parameters on Power Source display, such |

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

| as WFS, match those on wire feeder |

|

|

|

|

|

|

|

| display, if not, try changing Synergic 7F |

|

|

|

|

|

|

|

| control board. If problem persists refer to |

|

|

|

|

|

|

|

| Power Source trouble shooting information. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 29 –