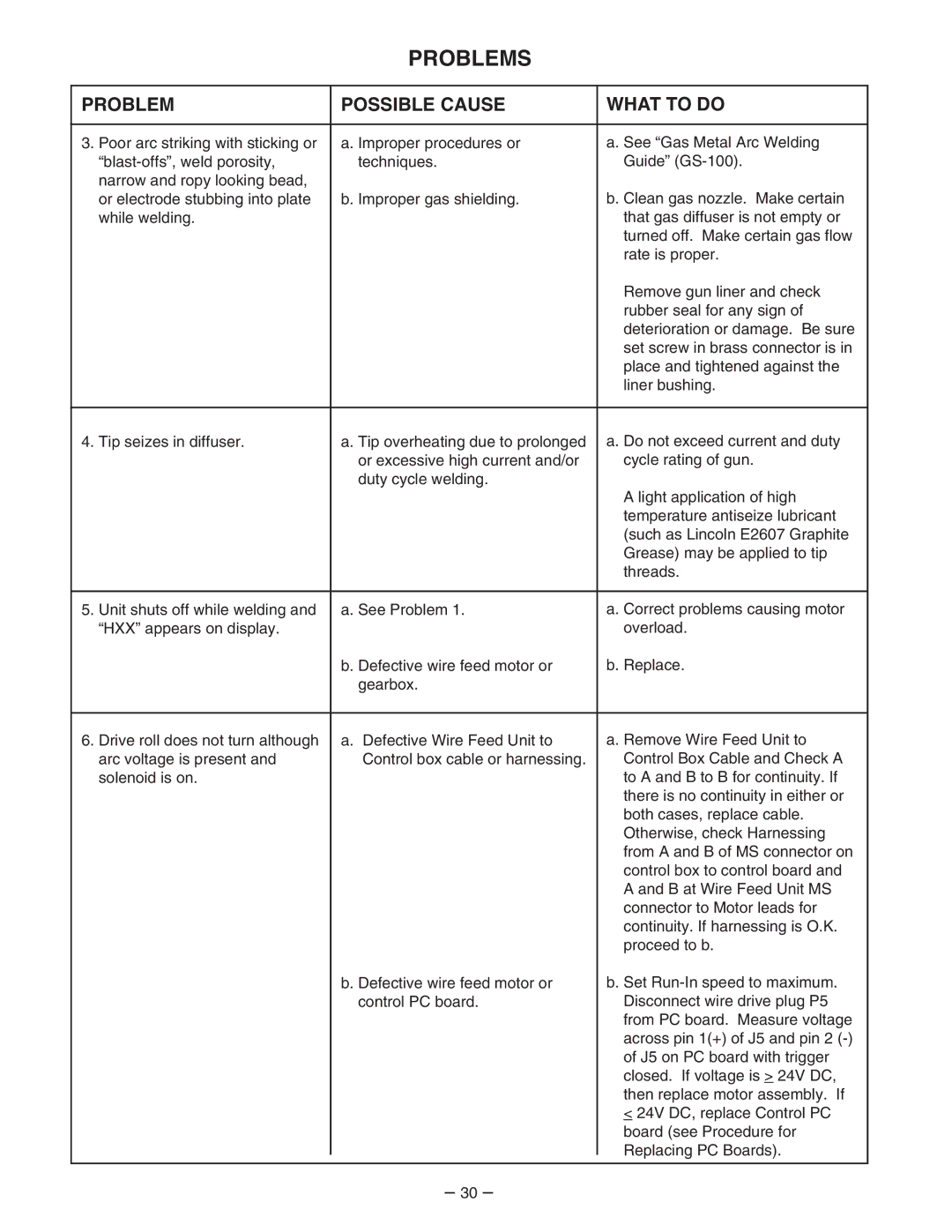

PROBLEMS

|

|

|

|

|

|

|

|

|

| PROBLEM |

|

| POSSIBLE CAUSE |

|

| WHAT TO DO |

|

|

|

|

|

|

|

|

|

|

| 3. Poor arc striking with sticking or |

|

| a. Improper procedures or |

|

| a. See “Gas Metal Arc Welding |

|

|

|

| techniques. |

|

| Guide” |

| |

| narrow and ropy looking bead, |

|

|

|

|

|

|

|

| or electrode stubbing into plate |

|

| b. Improper gas shielding. |

|

| b. Clean gas nozzle. Make certain |

|

| while welding. |

|

|

|

|

| that gas diffuser is not empty or |

|

|

|

|

|

|

|

| turned off. Make certain gas flow |

|

|

|

|

|

|

|

| rate is proper. |

|

|

|

|

|

|

|

| Remove gun liner and check |

|

|

|

|

|

|

|

| rubber seal for any sign of |

|

|

|

|

|

|

|

| deterioration or damage. Be sure |

|

|

|

|

|

|

|

| set screw in brass connector is in |

|

|

|

|

|

|

|

| place and tightened against the |

|

|

|

|

|

|

|

| liner bushing. |

|

|

|

|

|

|

|

|

|

|

| 4. Tip seizes in diffuser. |

|

| a. Tip overheating due to prolonged |

|

| a. Do not exceed current and duty |

|

|

|

|

| or excessive high current and/or |

|

| cycle rating of gun. |

|

|

|

|

| duty cycle welding. |

|

|

|

|

|

|

|

|

|

|

| A light application of high |

|

|

|

|

|

|

|

| temperature antiseize lubricant |

|

|

|

|

|

|

|

| (such as Lincoln E2607 Graphite |

|

|

|

|

|

|

|

| Grease) may be applied to tip |

|

|

|

|

|

|

|

| threads. |

|

|

|

|

|

|

|

|

|

|

| 5. Unit shuts off while welding and |

|

| a. See Problem 1. |

|

| a. Correct problems causing motor |

|

| “HXX” appears on display. |

|

|

|

|

| overload. |

|

|

|

|

| b. Defective wire feed motor or |

|

| b. Replace. |

|

|

|

|

| gearbox. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 6. Drive roll does not turn although |

|

| a. Defective Wire Feed Unit to |

|

| a. Remove Wire Feed Unit to |

|

| arc voltage is present and |

|

| Control box cable or harnessing. |

|

| Control Box Cable and Check A |

|

| solenoid is on. |

|

|

|

|

| to A and B to B for continuity. If |

|

|

|

|

|

|

|

| there is no continuity in either or |

|

|

|

|

|

|

|

| both cases, replace cable. |

|

|

|

|

|

|

|

| Otherwise, check Harnessing |

|

|

|

|

|

|

|

| from A and B of MS connector on |

|

|

|

|

|

|

|

| control box to control board and |

|

|

|

|

|

|

|

| A and B at Wire Feed Unit MS |

|

|

|

|

|

|

|

| connector to Motor leads for |

|

|

|

|

|

|

|

| continuity. If harnessing is O.K. |

|

|

|

|

|

|

|

| proceed to b. |

|

|

|

|

| b. Defective wire feed motor or |

|

| b. Set |

|

|

|

|

| control PC board. |

|

| Disconnect wire drive plug P5 |

|

|

|

|

|

|

|

| from PC board. Measure voltage |

|

|

|

|

|

|

|

| across pin 1(+) of J5 and pin 2 |

|

|

|

|

|

|

|

| of J5 on PC board with trigger |

|

|

|

|

|

|

|

| closed. If voltage is > 24V DC, |

|

|

|

|

|

|

|

| then replace motor assembly. If |

|

|

|

|

|

|

|

| < 24V DC, replace Control PC |

|

|

|

|

|

|

|

| board (see Procedure for |

|

|

|

|

|

|

|

| Replacing PC Boards). |

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

– 30 –