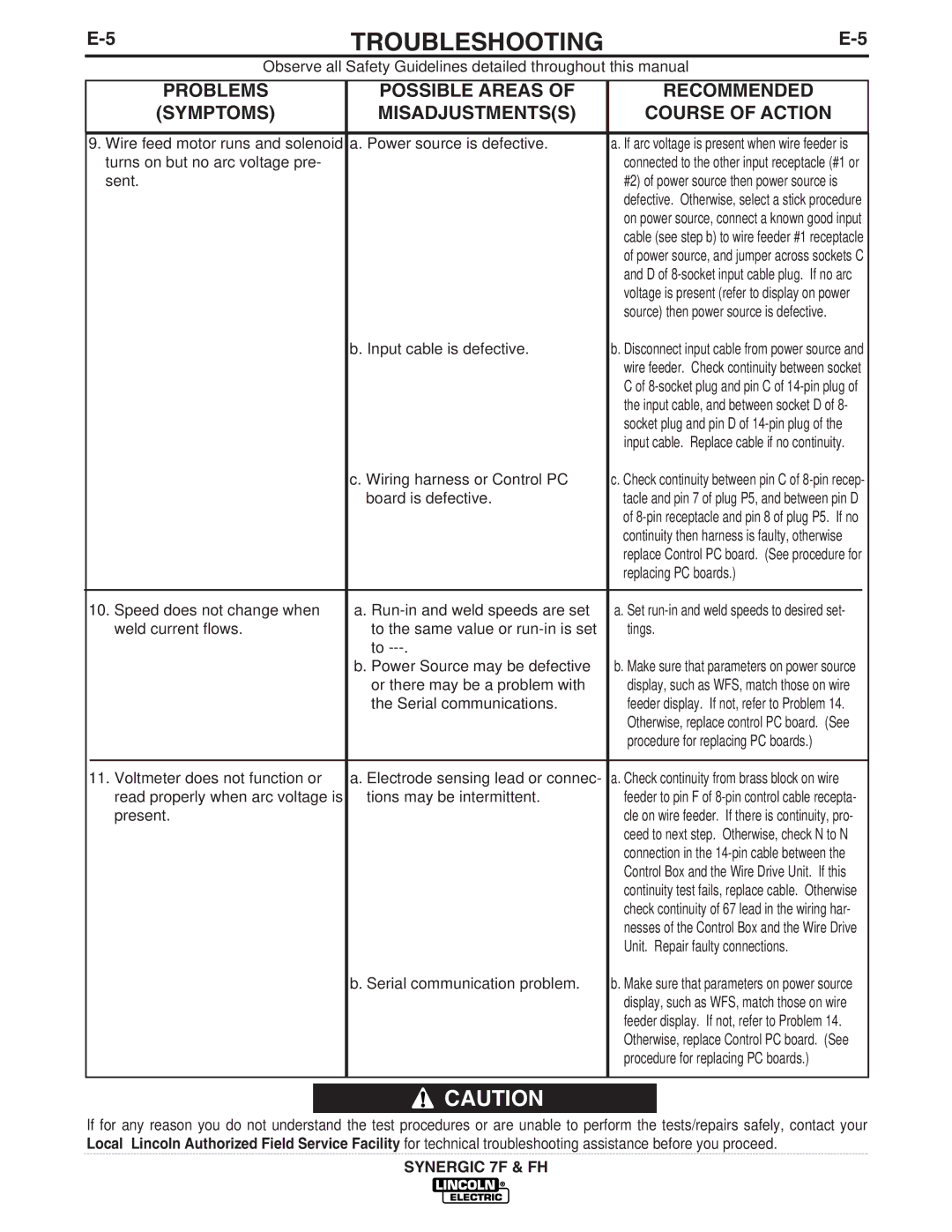

TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

9. Wire feed motor runs and solenoid | a. Power source is defective. | a. If arc voltage is present when wire feeder is | ||

| turns on but no arc voltage pre- |

| connected to the other input receptacle (#1 or | |

| sent. |

| #2) of power source then power source is | |

|

|

| defective. Otherwise, select a stick procedure | |

|

|

| on power source, connect a known good input | |

|

|

| cable (see step b) to wire feeder #1 receptacle | |

|

|

| of power source, and jumper across sockets C | |

|

|

| and D of | |

|

|

| voltage is present (refer to display on power | |

|

|

| source) then power source is defective. | |

|

| b. Input cable is defective. | b. Disconnect input cable from power source and | |

|

|

| wire feeder. Check continuity between socket | |

|

|

| C of | |

|

|

| the input cable, and between socket D of 8- | |

|

|

| socket plug and pin D of | |

|

|

| input cable. Replace cable if no continuity. | |

|

| c. Wiring harness or Control PC | c. Check continuity between pin C of | |

|

| board is defective. | tacle and pin 7 of plug P5, and between pin D | |

|

|

| of | |

|

|

| continuity then harness is faulty, otherwise | |

|

|

| replace Control PC board. (See procedure for | |

|

|

| replacing PC boards.) | |

|

|

|

|

|

10. Speed does not change when | a. | a. Set | ||

| weld current flows. | to the same value or | tings. | |

|

| to |

|

|

|

| b. Power Source may be defective | b. Make sure that parameters on power source | |

|

| or there may be a problem with | display, such as WFS, match those on wire | |

|

| the Serial communications. | feeder display. If not, refer to Problem 14. | |

|

|

| Otherwise, replace control PC board. (See | |

|

|

| procedure for replacing PC boards.) | |

|

|

|

| |

11. Voltmeter does not function or | a. Electrode sensing lead or connec- | a. Check continuity from brass block on wire | ||

| read properly when arc voltage is | tions may be intermittent. | feeder to pin F of | |

| present. |

| cle on wire feeder. If there is continuity, pro- | |

|

|

| ceed to next step. Otherwise, check N to N | |

|

|

| connection in the | |

|

|

| Control Box and the Wire Drive Unit. If this | |

|

|

| continuity test fails, replace cable. Otherwise | |

|

|

| check continuity of 67 lead in the wiring har- | |

|

|

| nesses of the Control Box and the Wire Drive | |

|

|

| Unit. Repair faulty connections. | |

|

| b. Serial communication problem. | b. Make sure that parameters on power source | |

|

|

| display, such as WFS, match those on wire | |

|

|

| feeder display. If not, refer to Problem 14. | |

|

|

| Otherwise, replace Control PC board. (See | |

|

|

| procedure for replacing PC boards.) | |

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

SYNERGIC 7F & FH