INSTALLATION | ||

|

|

|

Connect the one end of the electrode cable, to the power source output terminal of the desired polarity. Connect the other end of the electrode cable to the connection bar at the front of the wire drive feed plate using the provided bolt and lockwasher. The e l e c - trode cable lug must be against the feed plate. Be sure the cable, connection bar, and gun adapter bush- ing all make tight

WORK CABLE CONNECTIONS

Connect a work lead of sufficient size and length (per the following table) between the proper output termi- nal on the power source and the work. Be sure the connection to the work makes tight

To avoid interference problems with other equipment and to achieve the best possible operation, route all cables directly to the work or wire feeder. Avoid excessive lengths, bundle the electrode and ground cables together where practical, and do not coil excess cable.

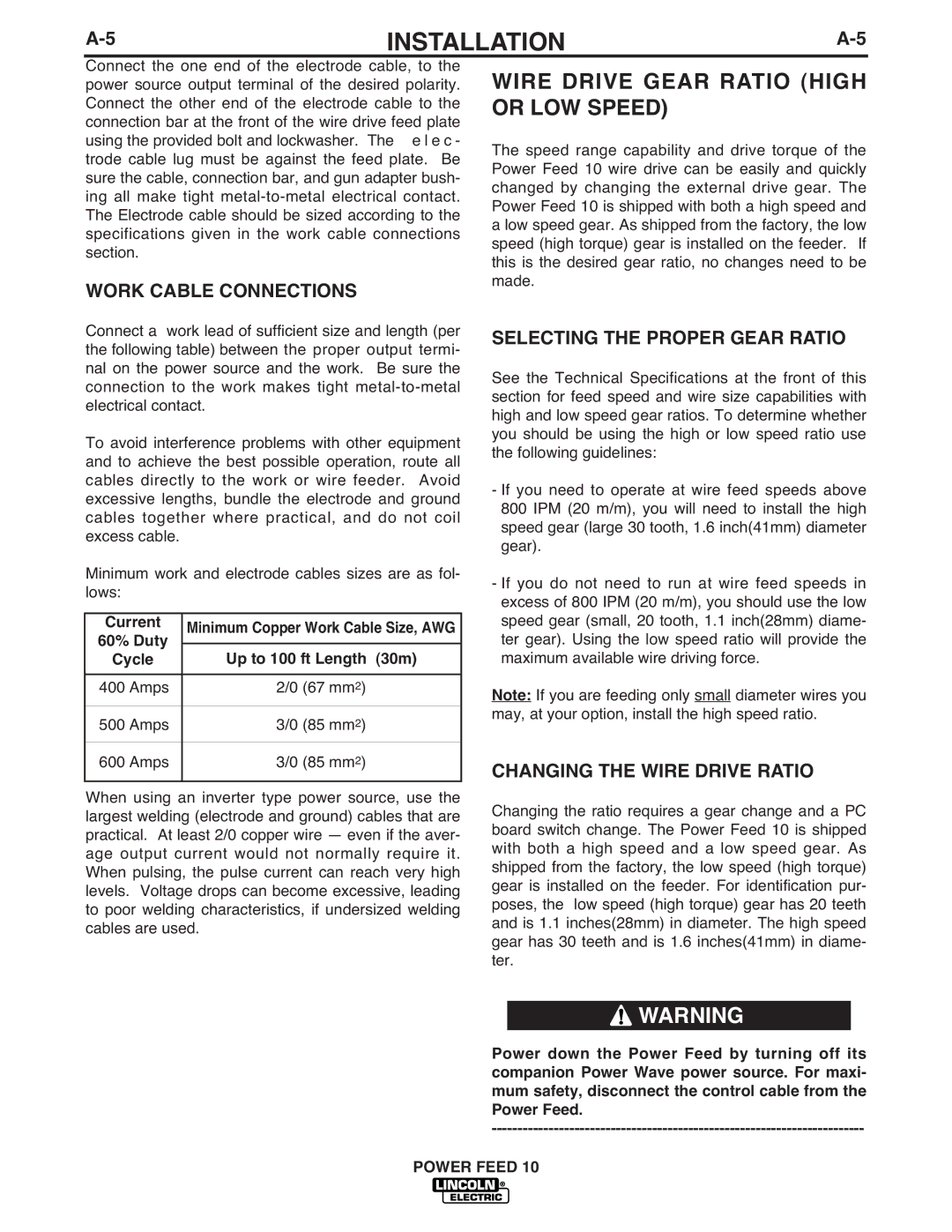

Minimum work and electrode cables sizes are as fol- lows:

Current |

| Minimum Copper Work Cable Size, AWG |

|

60% Duty |

|

|

|

| Up to 100 ft Length (30m) |

| |

Cycle |

|

| |

|

|

|

|

400 Amps |

| 2/0 (67 mm2) |

|

|

|

|

|

500 Amps |

| 3/0 (85 mm2) |

|

600 Amps |

| 3/0 (85 mm2) |

|

|

|

|

|

When using an inverter type power source, use the largest welding (electrode and ground) cables that are practical. At least 2/0 copper wire — even if the aver- age output current would not normally require it. When pulsing, the pulse current can reach very high levels. Voltage drops can become excessive, leading to poor welding characteristics, if undersized welding cables are used.

WIRE DRIVE GEAR RATIO (HIGH OR LOW SPEED)

The speed range capability and drive torque of the Power Feed 10 wire drive can be easily and quickly changed by changing the external drive gear. The Power Feed 10 is shipped with both a high speed and a low speed gear. As shipped from the factory, the low speed (high torque) gear is installed on the feeder. If this is the desired gear ratio, no changes need to be made.

SELECTING THE PROPER GEAR RATIO

See the Technical Specifications at the front of this section for feed speed and wire size capabilities with high and low speed gear ratios. To determine whether you should be using the high or low speed ratio use the following guidelines:

-If you need to operate at wire feed speeds above 800 IPM (20 m/m), you will need to install the high speed gear (large 30 tooth, 1.6 inch(41mm) diameter gear).

-If you do not need to run at wire feed speeds in excess of 800 IPM (20 m/m), you should use the low speed gear (small, 20 tooth, 1.1 inch(28mm) diame- ter gear). Using the low speed ratio will provide the maximum available wire driving force.

Note: If you are feeding only small diameter wires you may, at your option, install the high speed ratio.

CHANGING THE WIRE DRIVE RATIO

Changing the ratio requires a gear change and a PC board switch change. The Power Feed 10 is shipped with both a high speed and a low speed gear. As shipped from the factory, the low speed (high torque) gear is installed on the feeder. For identification pur- poses, the low speed (high torque) gear has 20 teeth and is 1.1 inches(28mm) in diameter. The high speed gear has 30 teeth and is 1.6 inches(41mm) in diame- ter.

![]() WARNING

WARNING

Power down the Power Feed by turning off its companion Power Wave power source. For maxi- mum safety, disconnect the control cable from the Power Feed.

POWER FEED 10