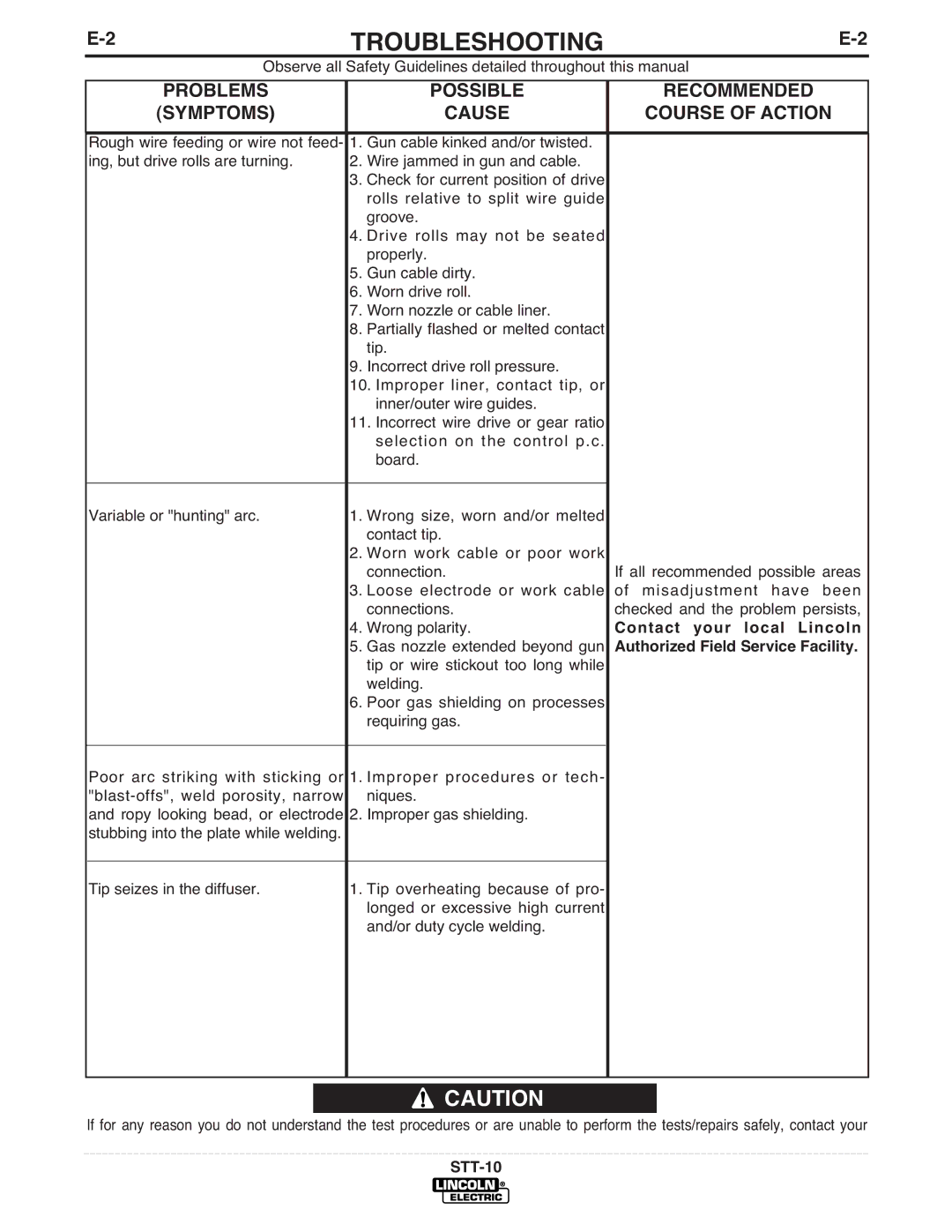

TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Rough wire feeding or wire not feed- | 1. | Gun cable kinked and/or twisted. |

ing, but drive rolls are turning. | 2. | Wire jammed in gun and cable. |

| 3. | Check for current position of drive |

|

| rolls relative to split wire guide |

|

| groove. |

| 4. | Drive rolls may not be seated |

|

| properly. |

| 5. | Gun cable dirty. |

| 6. | Worn drive roll. |

| 7. | Worn nozzle or cable liner. |

| 8. | Partially flashed or melted contact |

|

| tip. |

| 9. | Incorrect drive roll pressure. |

| 10. Improper liner, contact tip, or | |

|

| inner/outer wire guides. |

| 11. Incorrect wire drive or gear ratio | |

|

| selection on the control p.c. |

|

| board. |

|

|

|

Variable or "hunting" arc. | 1. | Wrong size, worn and/or melted |

|

| contact tip. |

| 2. Worn work cable or poor work | |

|

| connection. |

| 3. | Loose electrode or work cable |

|

| connections. |

| 4. | Wrong polarity. |

| 5. | Gas nozzle extended beyond gun |

|

| tip or wire stickout too long while |

|

| welding. |

| 6. | Poor gas shielding on processes |

|

| requiring gas. |

|

|

|

Poor arc striking with sticking or | 1. | Improper procedures or tech- |

| niques. | |

and ropy looking bead, or electrode | 2. | Improper gas shielding. |

stubbing into the plate while welding. |

|

|

|

|

|

Tip seizes in the diffuser. | 1. | Tip overheating because of pro- |

|

| longed or excessive high current |

|

| and/or duty cycle welding. |

|

|

|

If all recommended possible areas of misadjustment have been checked and the problem persists,

Contact your local Lincoln Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your