|

|

|

|

|

| INSTALLATION |

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

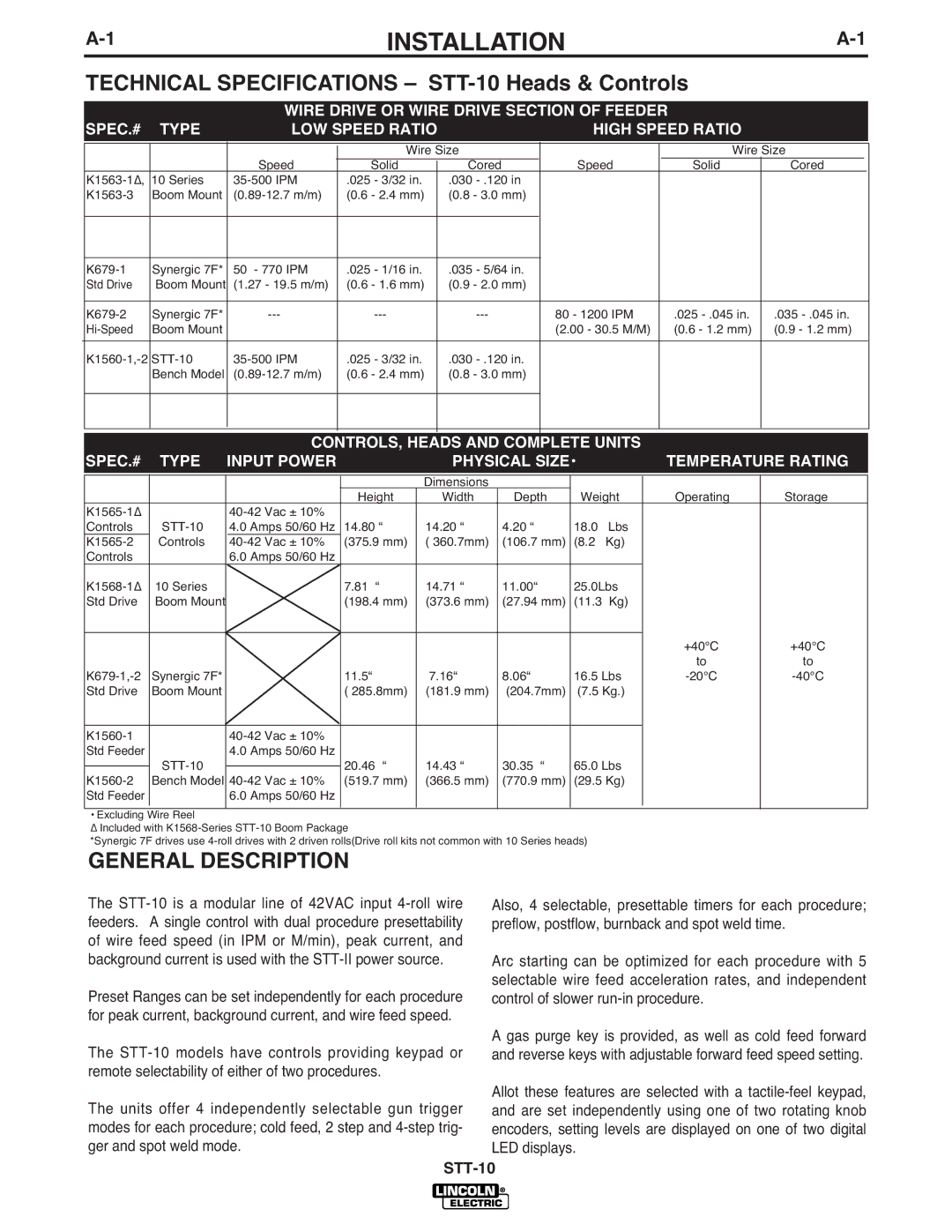

| TECHNICAL SPECIFICATIONS – |

|

| |||||||||||||||||

| SPEC.# | TYPE |

| WIRE DRIVE OR WIRE DRIVE SECTION OF FEEDER |

|

| ||||||||||||||

|

| LOW SPEED RATIO |

|

|

| HIGH SPEED RATIO |

|

| ||||||||||||

|

|

|

|

| Speed |

| Wire Size |

|

|

| Speed | Wire Size | ||||||||

|

|

|

|

|

|

|

|

| ||||||||||||

|

|

|

|

|

| Solid |

| Cored |

|

|

| Solid | Cored |

| ||||||

| 10 Series |

| .025 - 3/32 in. |

| .030 |

|

|

|

|

|

|

| ||||||||

| Boom Mount |

| (0.6 - 2.4 mm) |

| (0.8 - 3.0 mm) |

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

| Synergic 7F* |

| 50 - 770 IPM | .025 - 1/16 in. |

| .035 - 5/64 in. |

|

|

|

|

|

|

| |||||||

| Std Drive | Boom Mount | (1.27 - 19.5 m/m) | (0.6 - 1.6 mm) |

| (0.9 - 2.0 mm) |

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

| Synergic 7F* |

|

|

|

|

|

|

| 80 - 1200 IPM | .025 | .035 | |||||||||

| Boom Mount |

|

|

|

|

|

|

|

|

|

| (2.00 - 30.5 M/M) | (0.6 - 1.2 mm) | (0.9 - 1.2 mm) | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

| .025 - 3/32 in. |

| .030 |

|

|

|

|

|

|

| |||||||||

|

|

| Bench Model |

| (0.6 - 2.4 mm) |

| (0.8 - 3.0 mm) |

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SPEC.# | TYPE |

| CONTROLS, HEADS AND COMPLETE UNITS | TEMPERATURE RATING | |||||||||||||||

| INPUT POWER |

|

|

| PHYSICAL SIZE• |

|

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| Dimensions |

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| Height |

|

| Width |

| Depth | Weight |

| Operating | Storage | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

| Controls |

| 4.0 Amps 50/60 Hz | 14.80 “ |

| 14.20 “ |

| 4.20 “ | 18.0 | Lbs |

|

|

|

| ||||||

| Controls |

| (375.9 mm) |

| ( 360.7mm) |

| (106.7 mm) | (8.2 | Kg) |

|

|

|

| |||||||

| Controls |

|

| 6.0 Amps 50/60 Hz |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| 10 Series |

|

|

| 7.81 “ |

| 14.71 “ |

| 11.00“ | 25.0Lbs |

|

|

|

| ||||||

| Std Drive | Boom Mount |

|

|

| (198.4 mm) |

| (373.6 mm) |

| (27.94 mm) | (11.3 Kg) |

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| +40°C | +40°C | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| to | to | |

| Synergic 7F* |

|

|

| 11.5“ |

| 7.16“ |

| 8.06“ | 16.5 Lbs |

| |||||||||

| Std Drive | Boom Mount |

|

|

| ( 285.8mm) |

| (181.9 mm) |

| (204.7mm) | (7.5 Kg.) |

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

| Std Feeder |

|

| 4.0 Amps 50/60 Hz |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

| 20.46 “ |

| 14.43 “ |

| 30.35 “ | 65.0 Lbs |

|

|

|

| |||||

|

|

|

|

|

|

|

|

| ||||||||||||

| Bench Model | (519.7 mm) |

| (366.5 mm) |

| (770.9 mm) | (29.5 Kg) |

|

|

|

| |||||||||

| Std Feeder |

|

| 6.0 Amps 50/60 Hz |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Excluding Wire Reel

Δ Included with

*Synergic 7F drives use

GENERAL DESCRIPTION

The

Preset Ranges can be set independently for each procedure for peak current, background current, and wire feed speed.

The

The units offer 4 independently selectable gun trigger modes for each procedure; cold feed, 2 step and

Also, 4 selectable, presettable timers for each procedure; preflow, postflow, burnback and spot weld time.

Arc starting can be optimized for each procedure with 5 selectable wire feed acceleration rates, and independent control of slower

A gas purge key is provided, as well as cold feed forward and reverse keys with adjustable forward feed speed setting.

Allot these features are selected with a