OPERATION | ||

|

|

|

WIRE REEL CHANGING

At the end of a coil, remove the last of the old electrode coil from the conductor cable by either pulling it out at the nozzle end of the gun or by using the following pro- cedure:

1)Cut the end of the electrode off at the gun end. Do not break it off by hand because this puts a slight bend in the wire making it difficult to pull it back through the nozzle.

2)Disconnect the gun cable from the gun connector on the

3)Using pliers to grip the wire, pull it out of the cable from the connector end.

4)After the electrode has been removed, reconnect the gun cable to the drive. Load a new reel of elec- trode per the instructions in “Wire Reel Loading” in this section.

WIRE FEED OVERLOAD PROTECTION

The

GROUNDING LEAD PROTECTOR

The frame of the

If such a grounding lead fault occurs, the WFS display will show “GLP,” (with blank Voltage display) and the trigger circuit will be disabled. To reset the circuit, release the trigger, make sure that the electrode is not touching the wire feeder frame, and then either press any key on the keypad or close the trigger. When the GLP circuit is reset, the “GLP” display is removed and the wire feeder is returned to normal operating mode.

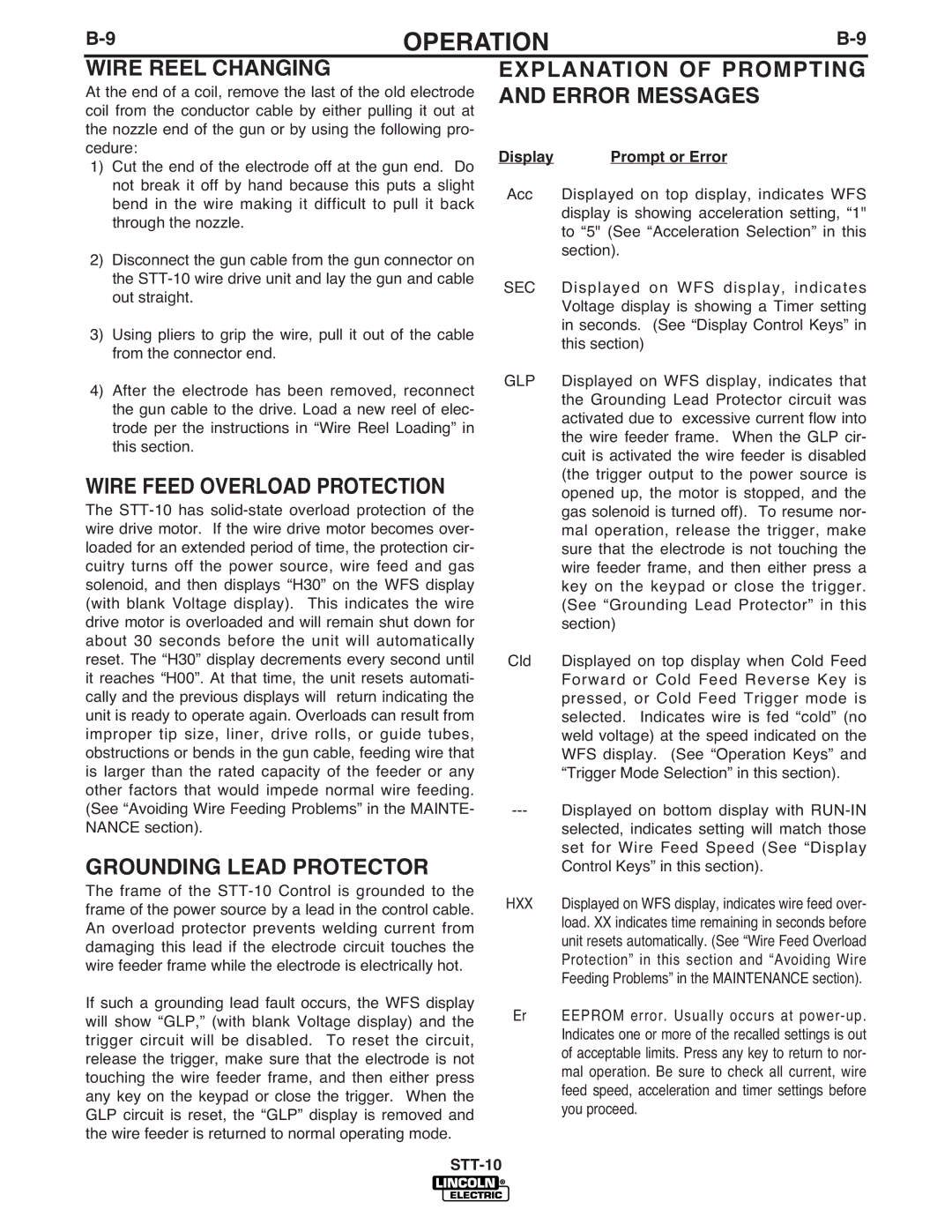

EXPLANATION OF PROMPTING AND ERROR MESSAGES

Display | Prompt or Error |

Acc | Displayed on top display, indicates WFS |

| display is showing acceleration setting, “1" |

| to “5" (See “Acceleration Selection” in this |

| section). |

SEC | Displayed on WFS display, indicates |

| Voltage display is showing a Timer setting |

| in seconds. (See “Display Control Keys” in |

| this section) |

GLP | Displayed on WFS display, indicates that |

| the Grounding Lead Protector circuit was |

| activated due to excessive current flow into |

| the wire feeder frame. When the GLP cir- |

| cuit is activated the wire feeder is disabled |

| (the trigger output to the power source is |

| opened up, the motor is stopped, and the |

| gas solenoid is turned off). To resume nor- |

| mal operation, release the trigger, make |

| sure that the electrode is not touching the |

| wire feeder frame, and then either press a |

| key on the keypad or close the trigger. |

| (See “Grounding Lead Protector” in this |

| section) |

Cld | Displayed on top display when Cold Feed |

| Forward or Cold Feed Reverse Key is |

| pressed, or Cold Feed Trigger mode is |

| selected. Indicates wire is fed “cold” (no |

| weld voltage) at the speed indicated on the |

| WFS display. (See “Operation Keys” and |

| “Trigger Mode Selection” in this section). |

---Displayed on bottom display with

HXX | Displayed on WFS display, indicates wire feed over- |

| load. XX indicates time remaining in seconds before |

| unit resets automatically. (See “Wire Feed Overload |

| Protection” in this section and “Avoiding Wire |

| Feeding Problems” in the MAINTENANCE section). |

Er | EEPROM error. Usually occurs at |

| Indicates one or more of the recalled settings is out |

| of acceptable limits. Press any key to return to nor- |

| mal operation. Be sure to check all current, wire |

| feed speed, acceleration and timer settings before |

| you proceed. |