OPERATION | ||

|

|

|

KEYPAD AND DISPLAY OPERATION

|

| LINCOLN | R |

|

|

|

|

|

|

| |

COLD FEED | COLD FEED |

| GAS PURGE | A | |

FORWARD | REVERSE |

|

| ||

|

|

|

|

| WFS |

PEAK | BACKGROUND | A | REMOTE | B | |

CURRENT |

|

| PROCEDURE |

| |

| A |

|

|

|

|

|

|

|

|

| A CURRENT |

|

| COLD FEED |

|

|

|

|

|

|

| TRIGGER |

|

|

|

|

|

| |

Dual procedure settings, including; trigger mode, cold feed speed,

Operation Keys

|

|

| |

| SPOT |

|

|

| PEAK | MAX | |

| WFS | ||

|

|

| |

1 | PREFLOW | PEAK | MIN |

| SPOT | BACKGROUND MAX | |

|

|

| WIRE FEED SPEED |

| BURNBACK | BACKGROUND MIN | |

| 2 POSTFLOW | WFS | MAX |

|

| WFS | MIN |

CONTROL |

|

| RANGE |

THE LINCOLN ELECTRIC COMPANY | CLEVELAND, OHIO | U.S.A. | G3152 |

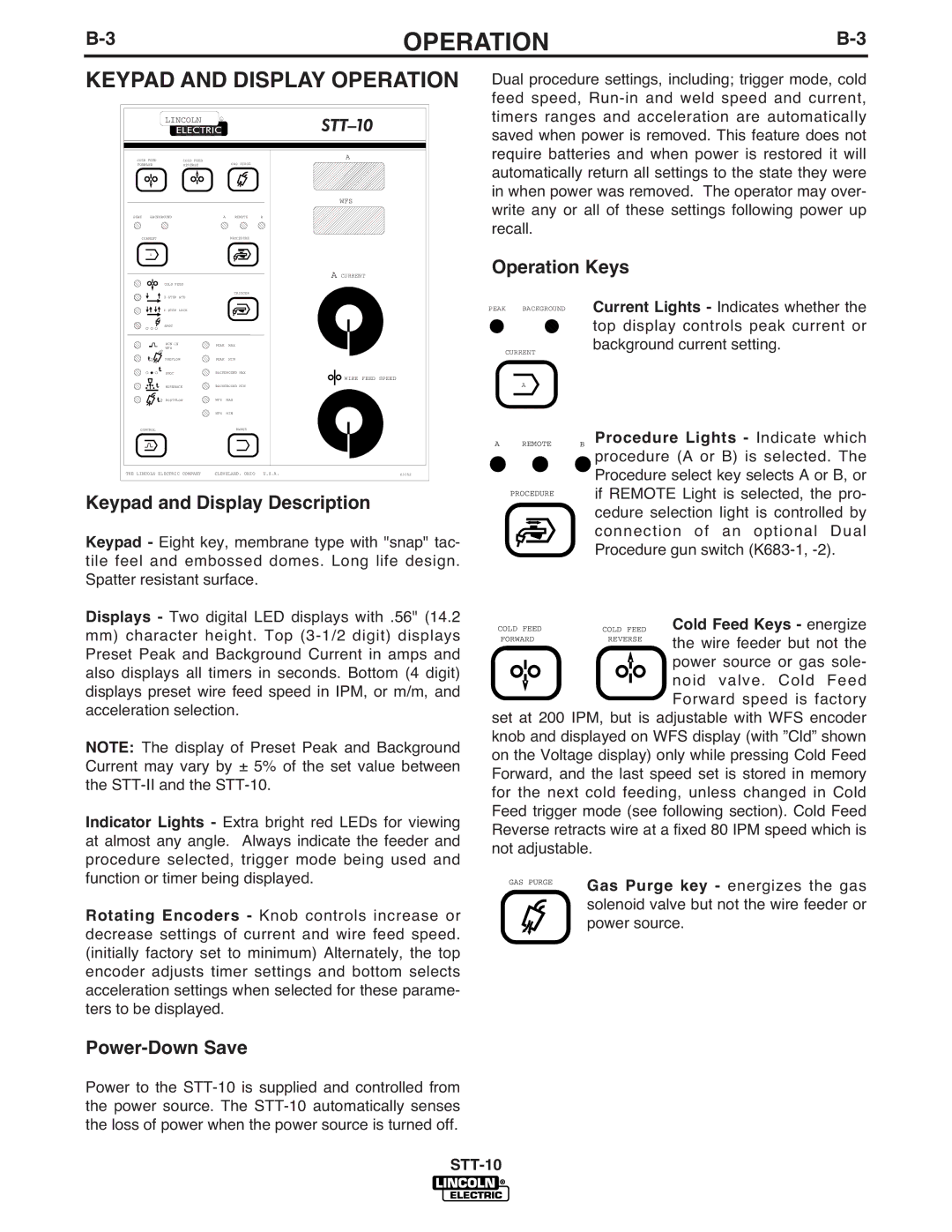

Keypad and Display Description

Keypad - Eight key, membrane type with "snap" tac- tile feel and embossed domes. Long life design. Spatter resistant surface.

PEAK BACKGROUND

CURRENT

A

AREMOTE

PROCEDURE

Current Lights - Indicates whether the top display controls peak current or background current setting.

BProcedure Lights - Indicate which ![]() procedure (A or B) is selected. The Procedure select key selects A or B, or if REMOTE Light is selected, the pro- cedure selection light is controlled by connection of an optional Dual Procedure gun switch

procedure (A or B) is selected. The Procedure select key selects A or B, or if REMOTE Light is selected, the pro- cedure selection light is controlled by connection of an optional Dual Procedure gun switch

Displays - Two digital LED displays with .56" (14.2

mm)character height. Top

NOTE: The display of Preset Peak and Background Current may vary by ± 5% of the set value between the

Indicator Lights - Extra bright red LEDs for viewing at almost any angle. Always indicate the feeder and procedure selected, trigger mode being used and function or timer being displayed.

Rotating Encoders - Knob controls increase or decrease settings of current and wire feed speed. (initially factory set to minimum) Alternately, the top encoder adjusts timer settings and bottom selects acceleration settings when selected for these parame- ters to be displayed.

Power-Down Save

Power to the

Cold Feed Keys - energize the wire feeder but not the power source or gas sole-

![]()

![]()

![]()

![]() noid valve. Cold Feed Forward speed is factory set at 200 IPM, but is adjustable with WFS encoder

noid valve. Cold Feed Forward speed is factory set at 200 IPM, but is adjustable with WFS encoder

knob and displayed on WFS display (with ”Cld” shown on the Voltage display) only while pressing Cold Feed Forward, and the last speed set is stored in memory for the next cold feeding, unless changed in Cold Feed trigger mode (see following section). Cold Feed Reverse retracts wire at a fixed 80 IPM speed which is not adjustable.

GAS PURGE | Gas Purge key - energizes the gas |

| |

| solenoid valve but not the wire feeder or |

| power source. |