OPERATION |

This mode is used for stick welding (SMAW) and

CCair

CV MIG provides a constant voltage output characteristic through the 13 to 44 volt range. The voltage is adjusted within this range by the Output Control dial.

The dynamic characteristics of this mode are ideal for open arc processes including, MIG/MAG (GMAW), Innershield®, and other cored wire (FCAW) processes. Faster travel submerged arc processes and CV air carbon- arc gouging may also use this mode. Refer to the Welding Performance Section.

CV

7.ARC FORCE CONTROL - This control is only func- tional in CC Stick mode. It prevents “stubbing” of the electrode by providing the extra weld current that linearly increases as the welding voltage decreases below a level determined by the setting of the constant current control.

The Arc Force control knob, located behind the latched cover, adjusts arc force from “Min” (no cur- rent increase) to “Max” (higher short circuit current). “Mid” position (#5) is recommended for most CC welding . Refer to the Welding Performance Section.

8.OPTIONAL VOLTMETER & AMMETER - Digital or analog meter kits are available as field installed options. Refer to the Accessories Section of this manual.

9.THERMAL PROTECTION LIGHT ![]() - If the machine overheats due to lack of proper air flow through the machine or due to exceeding the machine’s duty cycle, thermostats will disable the welding output and this light will illuminate. Input power is still applied to the machine and the cooling fan will continue to run. When the machine cools the welding output will resume.

- If the machine overheats due to lack of proper air flow through the machine or due to exceeding the machine’s duty cycle, thermostats will disable the welding output and this light will illuminate. Input power is still applied to the machine and the cooling fan will continue to run. When the machine cools the welding output will resume.

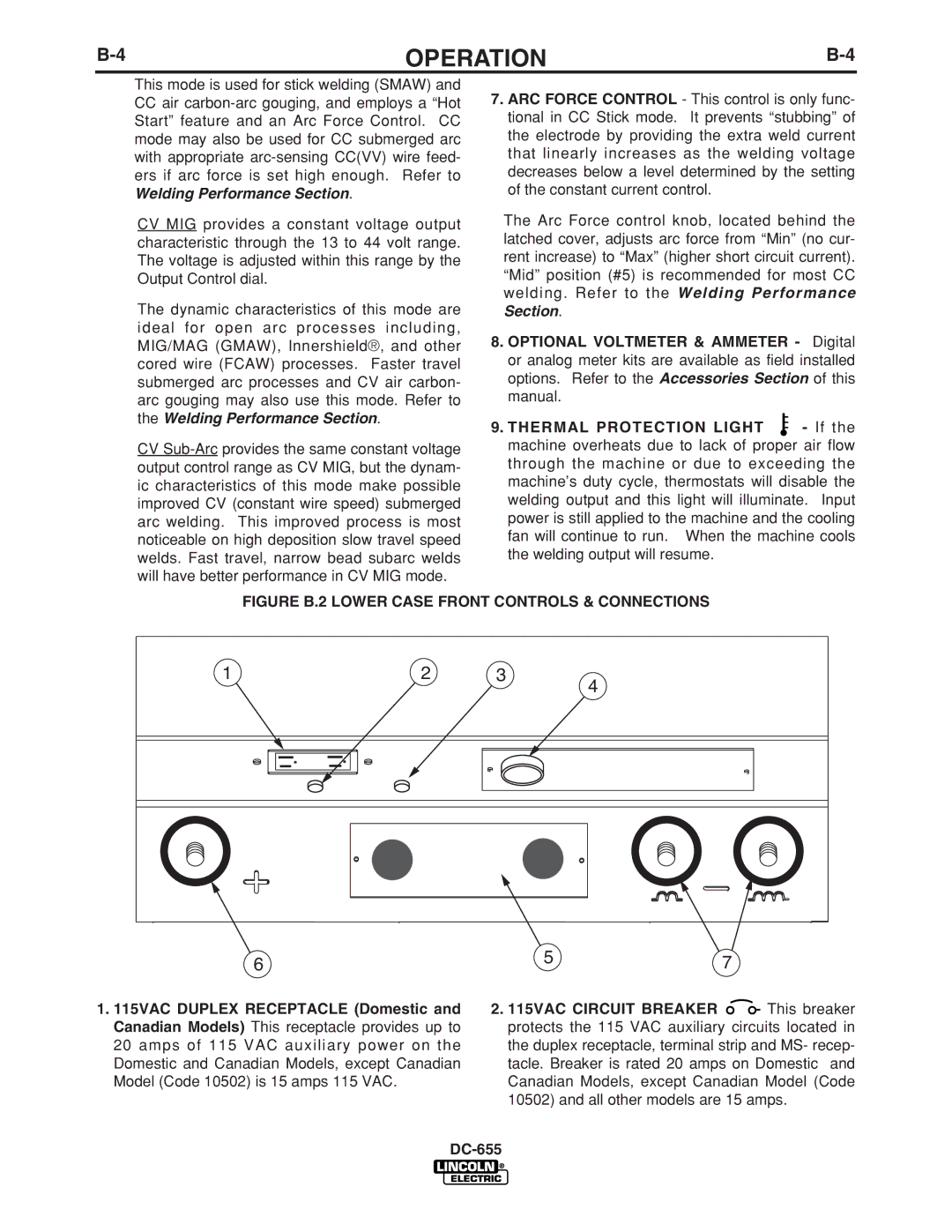

FIGURE B.2 LOWER CASE FRONT CONTROLS & CONNECTIONS

1 | 2 | 3 | 4 |

|

|

| |

6 |

| 5 | 7 |

1.115VAC DUPLEX RECEPTACLE (Domestic and Canadian Models) This receptacle provides up to 20 amps of 115 VAC auxiliary power on the Domestic and Canadian Models, except Canadian Model (Code 10502) is 15 amps 115 VAC.

2.115VAC CIRCUIT BREAKER ![]()

![]() - This breaker protects the 115 VAC auxiliary circuits located in the duplex receptacle, terminal strip and MS- recep- tacle. Breaker is rated 20 amps on Domestic and Canadian Models, except Canadian Model (Code 10502) and all other models are 15 amps.

- This breaker protects the 115 VAC auxiliary circuits located in the duplex receptacle, terminal strip and MS- recep- tacle. Breaker is rated 20 amps on Domestic and Canadian Models, except Canadian Model (Code 10502) and all other models are 15 amps.