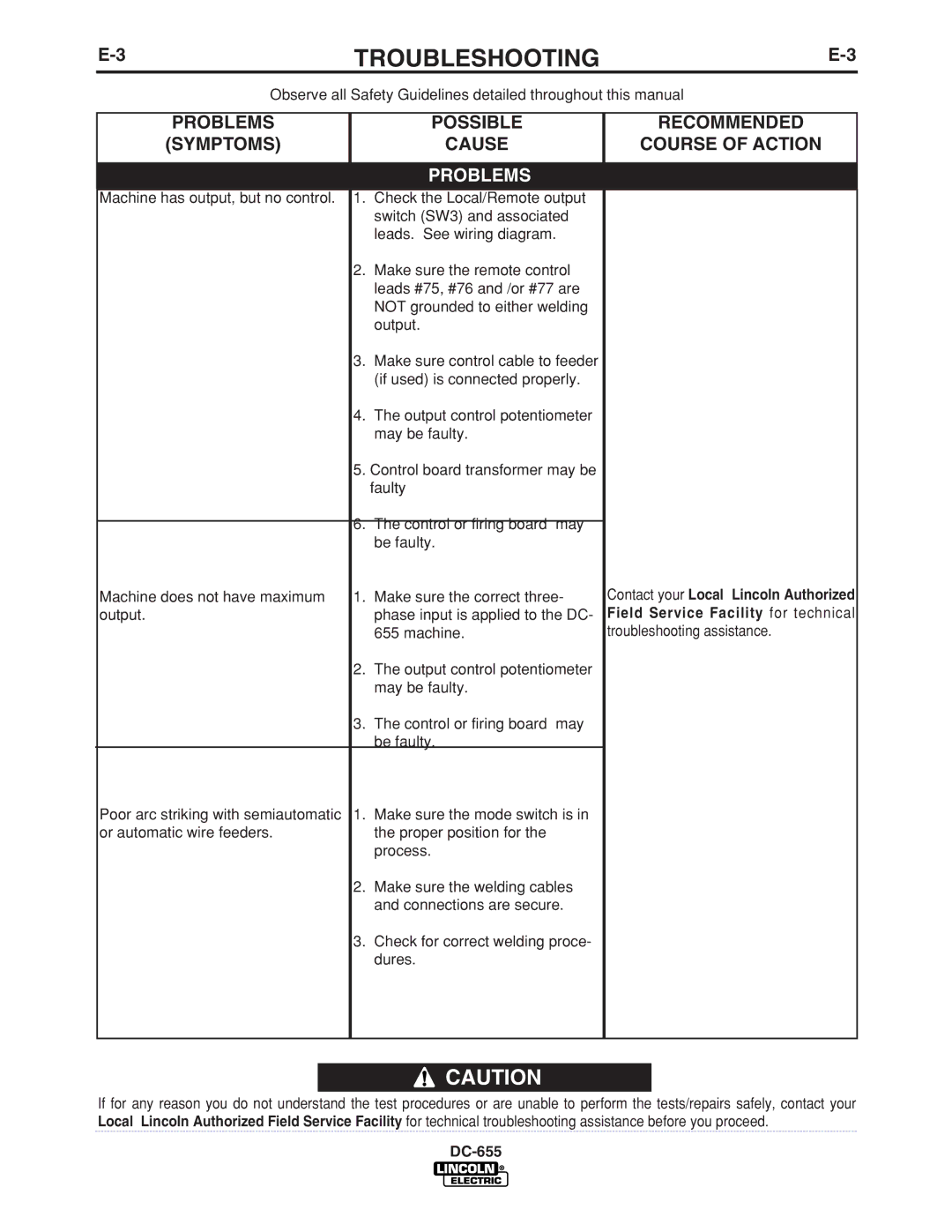

| TROUBLESHOOTING | |||

| Observe all Safety Guidelines detailed throughout this manual | |||

|

|

|

|

|

| PROBLEMS | POSSIBLE | RECOMMENDED |

|

| (SYMPTOMS) | CAUSE | COURSE OF ACTION |

|

|

|

|

|

|

PROBLEMS

Machine has output, but no control. | 1. Check the Local/Remote output | |

|

| switch (SW3) and associated |

|

| leads. See wiring diagram. |

| 2. | Make sure the remote control |

|

| leads #75, #76 and /or #77 are |

|

| NOT grounded to either welding |

|

| output. |

| 3. | Make sure control cable to feeder |

|

| (if used) is connected properly. |

| 4. | The output control potentiometer |

|

| may be faulty. |

| 5. | Control board transformer may be |

|

| faulty |

| 6. | The control or firing board may |

|

| be faulty. |

Machine does not have maximum | 1. Make sure the correct three- | |

output. |

| phase input is applied to the DC- |

|

| 655 machine. |

| 2. | The output control potentiometer |

|

| may be faulty. |

| 3. | The control or firing board may |

|

| be faulty. |

Poor arc striking with semiautomatic | 1. | Make sure the mode switch is in |

or automatic wire feeders. |

| the proper position for the |

|

| process. |

| 2. | Make sure the welding cables |

|

| and connections are secure. |

| 3. | Check for correct welding proce- |

|

| dures. |

|

|

|

Contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance.

![]()

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.