THERMAL SHUTDOWN

This welder has thermostatic protection from exces- sive duty cycles, overloads, loss of cooling, and high ambient temperature. When the welder is subjected to an overload or loss of cooling, a thermostat will open. This condition will be indicated by the illumination of the yellow Thermostatic Protection Light on the case front (see figure B.1). The fan will continue to run to cool the power source. No welding is possible until the machine is allowed to cool and the Thermostatic Protection Light goes out.

OVER CURRENT PROTECTION

SHUTDOWN

Average Current Shutdown

To protect the SCR’s , the DC-655 will shut down to essentially no output if the output current averages over 900 amps for about 5-6 seconds, and in less than 0.3 seconds if averaging over 1200 amps (short- er time for higher current). Control PC board LED4, shutdown light, will turn on.

This average current shut down can only be reset by opening the feeder gun trigger, or switching the DC- 655 Output/Remote switch out of the “on” position.

Peak Current Shutdown

To protect the SCR;s, the DC-655 will shut down immediately to essentially no output if the peak output current exceeds 2500 amps (about 1800A average). Control PC board LED4, shutdown light, will turn on.

This peak current shut down can be reset by turning the DC-655 input power off, then on.

REMOTE CONTROL LEADS FAULT PROTECTION SHUTDOWN

The remote control leads from the 14-pin receptacle or terminal strip are protected against high voltage faults to the electrode circuit or auxiliary voltage sup- plies. If such a fault occurs the DC-655 will shut down the input primary voltage to the transformer to prevent the fault output. Control PC board LED3, input shut- down light, turns on.

If this input shutdown occurs the input power pilot light remains lit, since the power switch is ON and control power is still present. Welding output or auxiliary sup- ply output will not be present

This input shut down is reset by turning the DC-655 input power off, then on. If the fault is not corrected however, the shutdown will re-occur when turning on the input power.

SHORTED RECTIFIER FAULT

PROTECTION

If a short occurs across one of the silicon controlled rectifiers of the DC-655, a potentially hazardous AC voltage could appear across the welding output termi- nals, even in idle mode when no output should be pre- sent. If such a fault occurs the DC-655 will shut down the input primary voltage to the transformer to prevent the fault output. Control PC board LED3, input shut- down light, turns on.

If this input shutdown occurs the input power pilot light remains lit, since the power switch is ON and control power is still present. Welding output or auxiliary sup- ply output will not be present

This input shut down is reset by turning the DC-655 input power off, then on. If the fault is not corrected however, the shutdown will re-occur when turning on the input power.

IDLE SHUT DOWN TIMER

For additional operating economy, the DC-655 can be set up to automatically shut off the primary input power to the main transformer after a selectable time (1/2 or 2 hr.) has expired without welding. The unex- pired timer is reset with each weld.

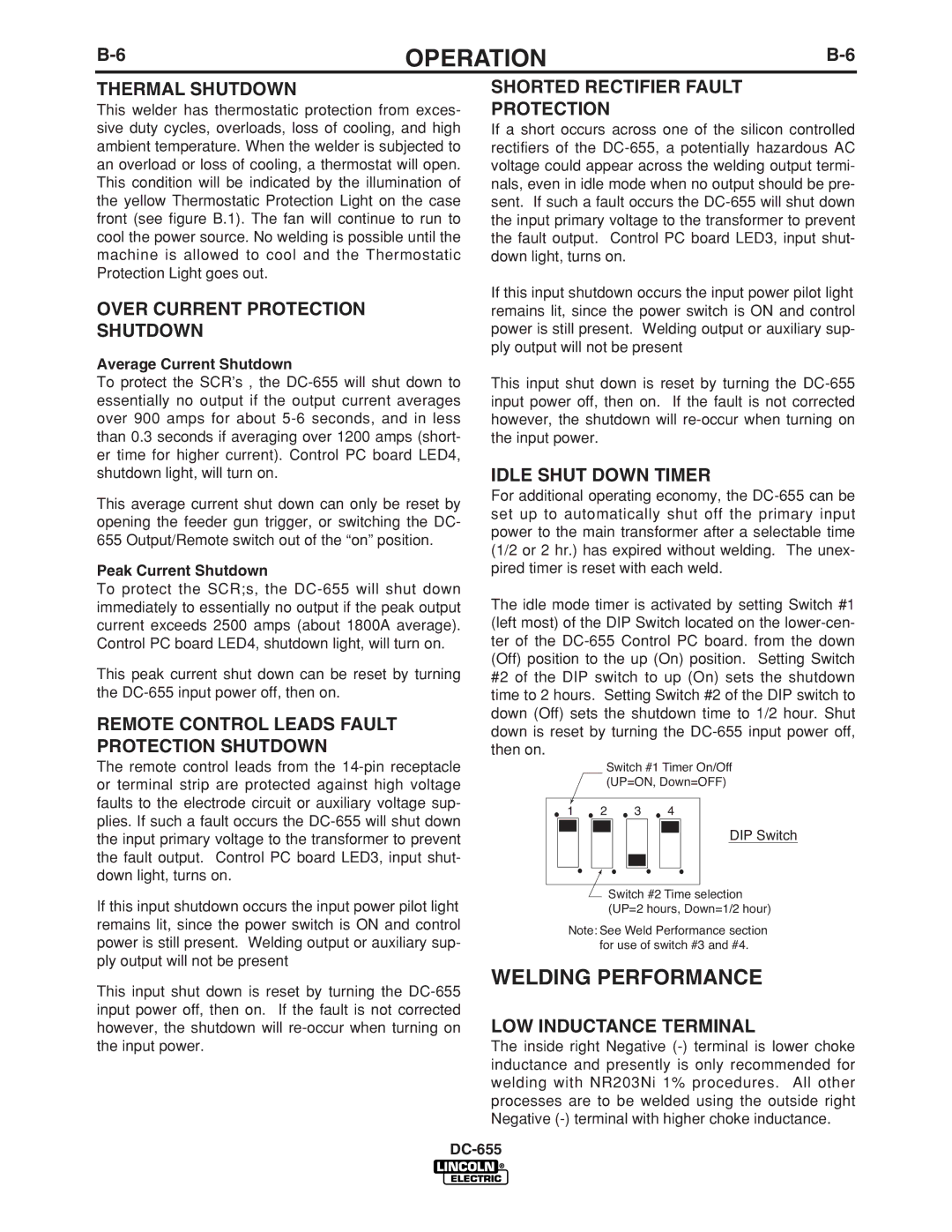

The idle mode timer is activated by setting Switch #1 (left most) of the DIP Switch located on the lower-cen- ter of the DC-655 Control PC board. from the down (Off) position to the up (On) position. Setting Switch #2 of the DIP switch to up (On) sets the shutdown time to 2 hours. Setting Switch #2 of the DIP switch to down (Off) sets the shutdown time to 1/2 hour. Shut down is reset by turning the DC-655 input power off, then on.

Switch #1 Timer On/Off

(UP=ON, Down=OFF)

1 2 3 4

DIP Switch

Switch #2 Time selection (UP=2 hours, Down=1/2 hour)

Switch #2 Time selection (UP=2 hours, Down=1/2 hour)

Note: See Weld Performance section for use of switch #3 and #4.

WELDING PERFORMANCE

LOW INDUCTANCE TERMINAL

The inside right Negative (-) terminal is lower choke inductance and presently is only recommended for welding with NR203Ni 1% procedures. All other processes are to be welded using the outside right Negative (-) terminal with higher choke inductance.

![]() Switch #2 Time selection (UP=2 hours, Down=1/2 hour)

Switch #2 Time selection (UP=2 hours, Down=1/2 hour)