INSTALLATION |

INPUT POWER SUPPLY CONNECTIONS

A qualified electrician should connect the input power supply leads.

1.Follow all national and local electrical codes.

2.Use a

3.Remove the input access door at upper rear of the machine.

4.Follow input supply connection diagram located on the inside the door. For multiple voltage machines, follow the diagram for the voltage that is within 10% of your actual input line voltage.

5.Connect the

RECONNECT PROCEDURE

![]() WARNING

WARNING

Electric Shock Can Kill

•Disconnect input power before perform- ing this procedure.

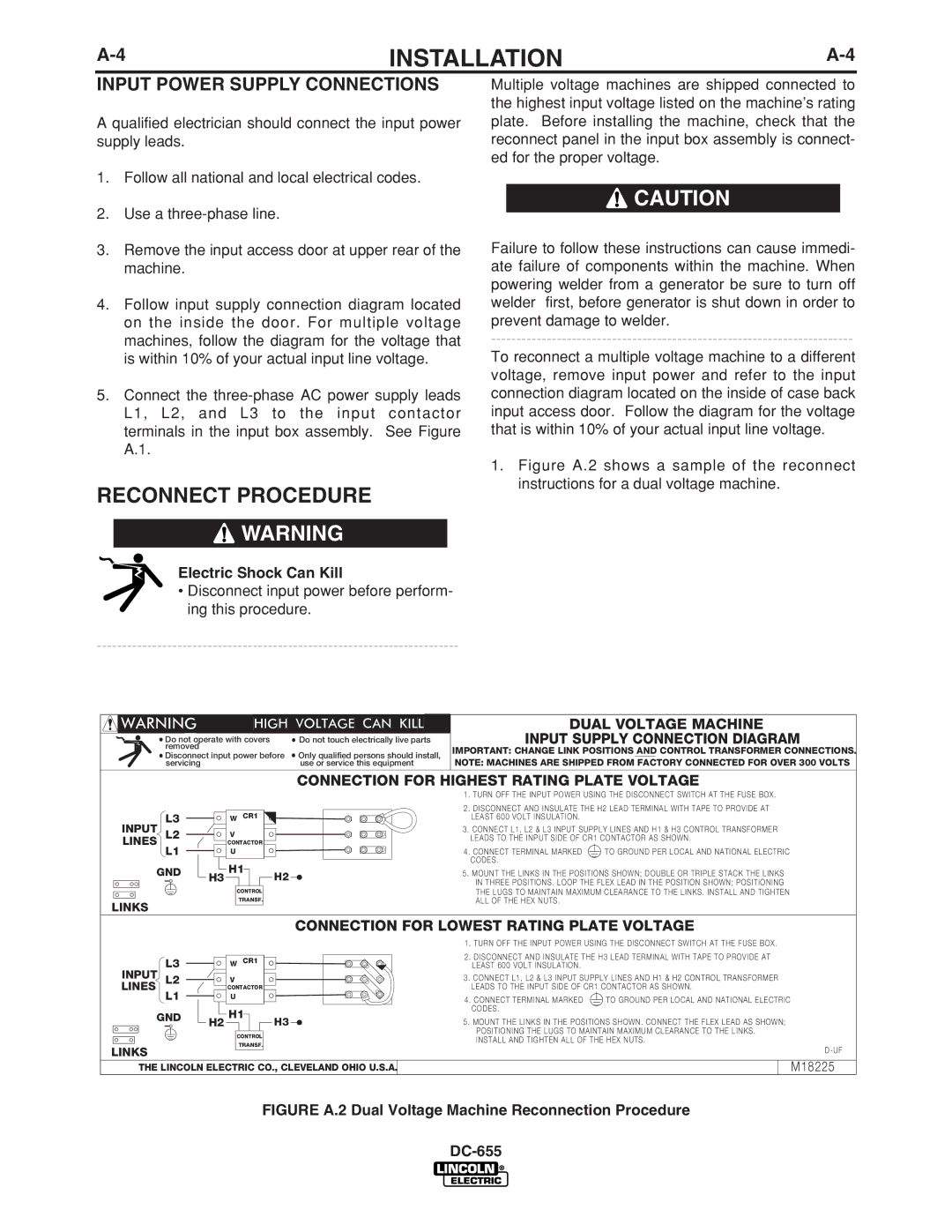

Multiple voltage machines are shipped connected to the highest input voltage listed on the machine’s rating plate. Before installing the machine, check that the reconnect panel in the input box assembly is connect- ed for the proper voltage.

![]() CAUTION

CAUTION

Failure to follow these instructions can cause immedi- ate failure of components within the machine. When powering welder from a generator be sure to turn off welder first, before generator is shut down in order to prevent damage to welder.

To reconnect a multiple voltage machine to a different voltage, remove input power and refer to the input connection diagram located on the inside of case back input access door. Follow the diagram for the voltage that is within 10% of your actual input line voltage.

1.Figure A.2 shows a sample of the reconnect instructions for a dual voltage machine.

Do not operate with covers | Do not touch electrically live parts |

removed | Only qualified persons should install, |

Disconnect input power before | |

servicing | use or service this equipment |

DUAL VOLTAGE MACHINE

INPUT SUPPLY CONNECTION DIAGRAM

IMPORTANT: CHANGE LINK POSITIONS AND CONTROL TRANSFORMER CONNECTIONS. NOTE: MACHINES ARE SHIPPED FROM FACTORY CONNECTED FOR OVER 300 VOLTS

L3 | W CR1 | |

INPUT | V | |

LINES L2 | ||

CONTACTOR | ||

L1 | U | |

GND | H1 | |

| H3 | |

| CONTROL | |

| TRANSF. |

LINKS

CONNECTION FOR HIGHEST RATING PLATE VOLTAGE

| 1 | . TURN OFF THE INPUT POWER USING THE DISCONNECT SWITCH AT THE FUSE BOX. | |

| 2 | . DISCONNECT AND INSULATE THE H2 LEAD TERMINAL WITH TAPE TO PROVIDE AT | |

|

| LEAST 600 VOLT INSULATION. |

|

| 3. CONNECT L1, L2 & L3 INPUT SUPPLY LINES AND H1 & H3 CONTROL TRANSFORMER | ||

|

| LEADS TO THE INPUT SIDE OF CR1 CONTACTOR AS SHOWN. | |

| 4 | . CONNECT TERMINAL MARKED | TO GROUND PER LOCAL AND NATIONAL ELECTRIC |

|

| CODES. |

|

H2 | 5. MOUNT THE LINKS IN THE POSITIONS SHOWN; DOUBLE OR TRIPLE STACK THE LINKS | ||

| IN THREE POSITIONS. LOOP THE FLEX LEAD IN THE POSITION SHOWN; POSITIONING | ||

|

| ||

|

| THE LUGS TO MAINTAIN MAXIMUM CLEARANCE TO THE LINKS. INSTALL AND TIGHTEN | |

|

| ALL OF THE HEX NUTS. |

|

|

|

|

| CONNECTION FOR LOWEST RATING PLATE VOLTAGE | ||

|

|

|

|

| 1. TURN OFF THE INPUT POWER USING THE DISCONNECT SWITCH AT THE FUSE BOX. | |

|

| L3 |

| W CR1 | 2. DISCONNECT AND INSULATE THE H3 LEAD TERMINAL WITH TAPE TO PROVIDE AT | |

INPUT |

| LEAST 600 VOLT INSULATION. |

| |||

L2 |

| V | 3. CONNECT L1, L2 & L3 INPUT SUPPLY LINES AND H1 & H2 CONTROL TRANSFORMER | |||

LINES |

|

| CONTACTOR | LEADS TO THE INPUT SIDE OF CR1 CONTACTOR AS SHOWN. | ||

|

| L1 |

| U | 4. CONNECT TERMINAL MARKED | TO GROUND PER LOCAL AND NATIONAL ELECTRIC |

| GND |

| H1 | CODES. |

| |

| H2 | 5. MOUNT THE LINKS IN THE POSITIONS SHOWN. CONNECT THE FLEX LEAD AS SHOWN; | ||||

|

|

| H3 | |||

|

|

|

| CONTROL | POSITIONING THE LUGS TO MAINTAIN MAXIMUM CLEARANCE TO THE LINKS. | |

|

|

|

| INSTALL AND TIGHTEN ALL OF THE HEX NUTS. | ||

|

|

|

| TRANSF. | ||

LINKS |

|

|

|

| ||

|

|

|

|

| ||

THE LINCOLN ELECTRIC CO., CLEVELAND OHIO U.S.A. |

| M18225 | ||||