OPERATION |

CV MODE CURRENT-LIMITING

CV MIG and CV

As shipped, the

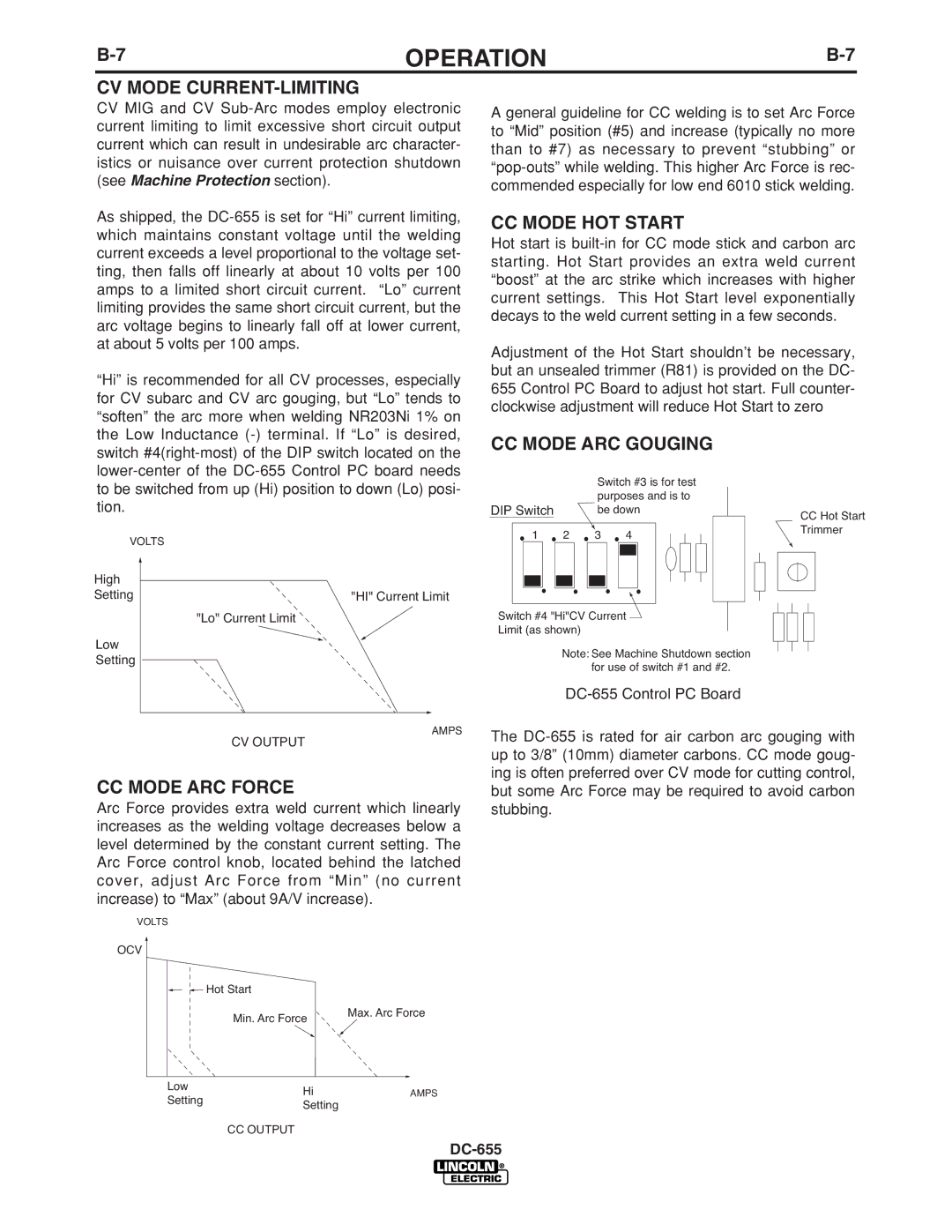

“Hi” is recommended for all CV processes, especially for CV subarc and CV arc gouging, but “Lo” tends to “soften” the arc more when welding NR203Ni 1% on the Low Inductance

A general guideline for CC welding is to set Arc Force to “Mid” position (#5) and increase (typically no more than to #7) as necessary to prevent “stubbing” or

CC MODE HOT START

Hot start is

Adjustment of the Hot Start shouldn’t be necessary, but an unsealed trimmer (R81) is provided on the DC- 655 Control PC Board to adjust hot start. Full counter- clockwise adjustment will reduce Hot Start to zero

switch

VOLTS |

|

High |

|

Setting | "HI" Current Limit |

| "Lo" Current Limit |

Low |

|

CC MODE ARC GOUGING

|

|

|

|

|

|

|

| Switch #3 is for test | |||||||||

|

|

|

|

|

|

|

| purposes and is to | |||||||||

DIP Switch |

|

|

| be down | |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

| 2 |

| 3 | 4 |

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Switch #4 "Hi"CV Current ![]()

Limit (as shown)

CCHot Start Trimmer

Setting |

AMPS |

CV OUTPUT

CC MODE ARC FORCE

Arc Force provides extra weld current which linearly increases as the welding voltage decreases below a level determined by the constant current setting. The Arc Force control knob, located behind the latched cover, adjust Arc Force from “Min” (no current increase) to “Max” (about 9A/V increase).

VOLTS |

|

| |

OCV |

|

| |

| Hot Start |

| |

| Min. Arc Force | Max. Arc Force | |

|

| ||

Low | Hi | AMPS | |

Setting | |||

Setting |

| ||

|

|

CC OUTPUT

Note: See Machine Shutdown section for use of switch #1 and #2.

The