TROUBLESHOOTING | ||

|

|

|

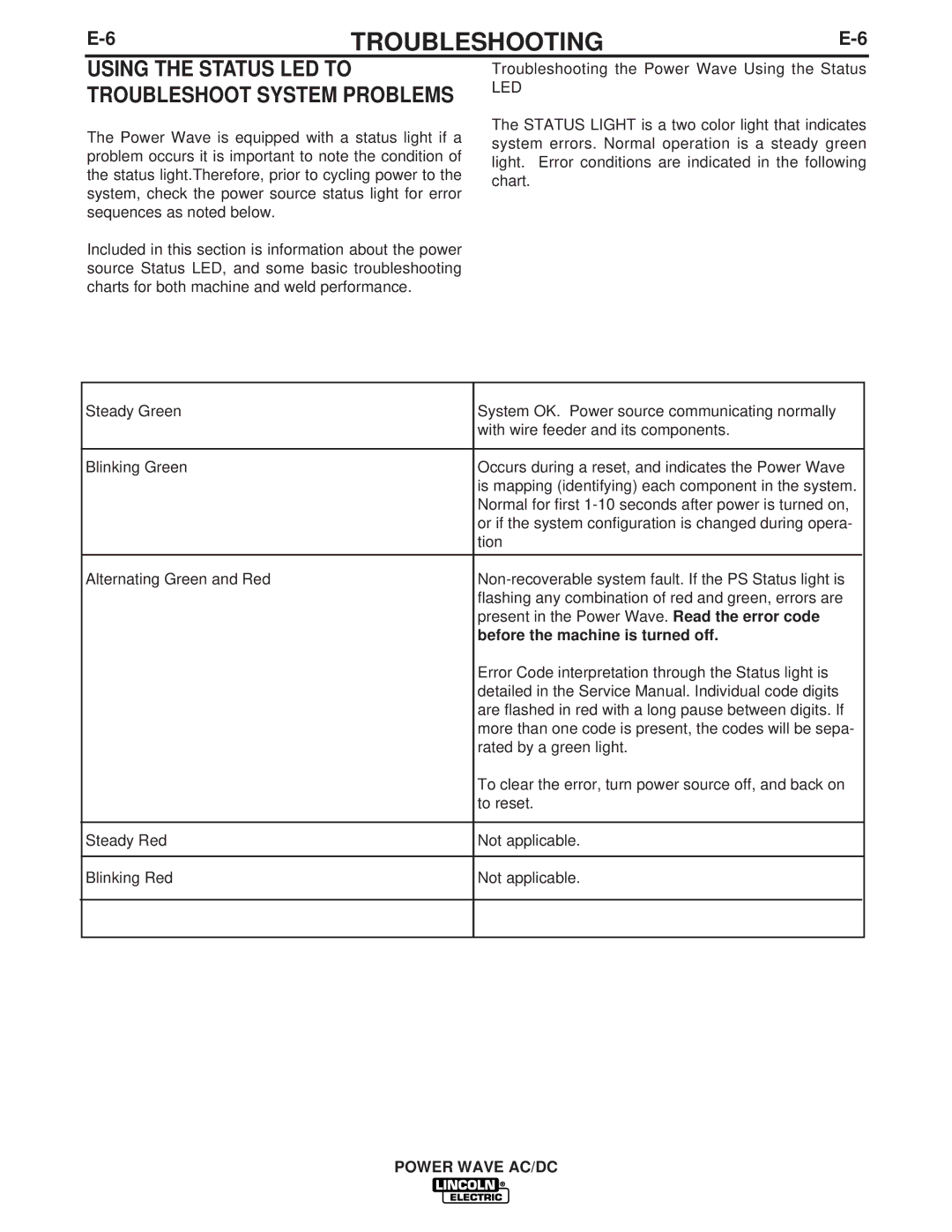

USING THE STATUS LED TO TROUBLESHOOT SYSTEM PROBLEMS

The Power Wave is equipped with a status light if a problem occurs it is important to note the condition of the status light.Therefore, prior to cycling power to the system, check the power source status light for error sequences as noted below.

Included in this section is information about the power source Status LED, and some basic troubleshooting charts for both machine and weld performance.

Troubleshooting the Power Wave Using the Status

LED

The STATUS LIGHT is a two color light that indicates system errors. Normal operation is a steady green light. Error conditions are indicated in the following chart.

Steady Green | System OK. Power source communicating normally |

| with wire feeder and its components. |

|

|

Blinking Green | Occurs during a reset, and indicates the Power Wave |

| is mapping (identifying) each component in the system. |

| Normal for first |

| or if the system configuration is changed during opera- |

| tion |

|

|

Alternating Green and Red | |

| flashing any combination of red and green, errors are |

| present in the Power Wave. Read the error code |

| before the machine is turned off. |

| Error Code interpretation through the Status light is |

| detailed in the Service Manual. Individual code digits |

| are flashed in red with a long pause between digits. If |

| more than one code is present, the codes will be sepa- |

| rated by a green light. |

| To clear the error, turn power source off, and back on |

| to reset. |

|

|

Steady Red | Not applicable. |

|

|

Blinking Red | Not applicable. |

|

|

|

|