OPERATION | ||

|

|

|

CASE FRONT CONTROLS

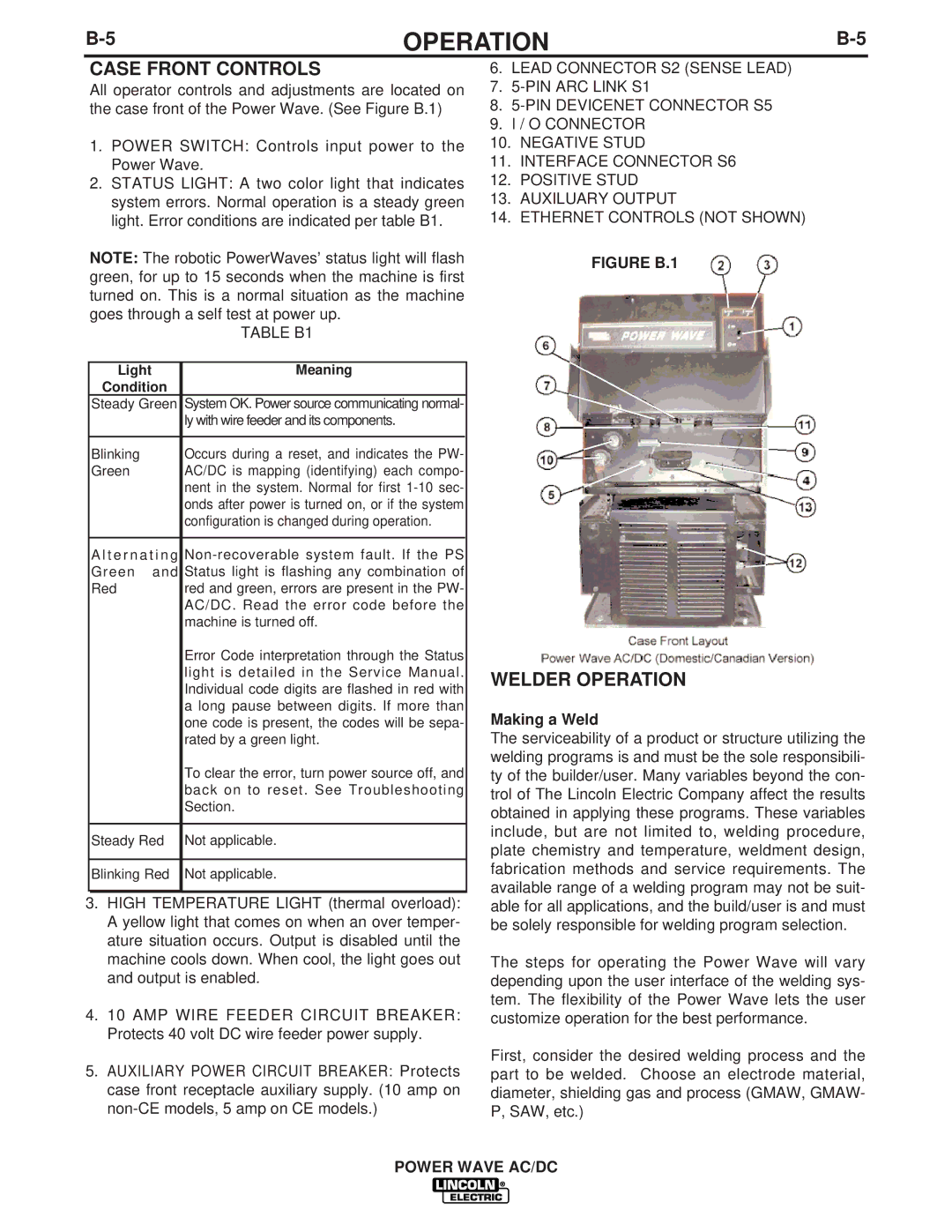

All operator controls and adjustments are located on the case front of the Power Wave. (See Figure B.1)

1.POWER SWITCH: Controls input power to the Power Wave.

2.STATUS LIGHT: A two color light that indicates system errors. Normal operation is a steady green light. Error conditions are indicated per table B1.

NOTE: The robotic PowerWaves’ status light will flash green, for up to 15 seconds when the machine is first turned on. This is a normal situation as the machine goes through a self test at power up.

TABLE B1

Light | Meaning |

Condition |

|

Steady Green | System OK. Power source communicating normal- |

| ly with wire feeder and its components. |

|

|

Blinking | Occurs during a reset, and indicates the PW- |

Green | AC/DC is mapping (identifying) each compo- |

| nent in the system. Normal for first |

| onds after power is turned on, or if the system |

| configuration is changed during operation. |

|

|

A l t e r n a t i n g | |

Green and | Status light is flashing any combination of |

Red | red and green, errors are present in the PW- |

| AC/DC. Read the error code before the |

| machine is turned off. |

| Error Code interpretation through the Status |

| light is detailed in the Service Manual. |

| Individual code digits are flashed in red with |

| a long pause between digits. If more than |

| one code is present, the codes will be sepa- |

| rated by a green light. |

| To clear the error, turn power source off, and |

| back on to reset. See Troubleshooting |

| Section. |

|

|

Steady Red | Not applicable. |

|

|

Blinking Red | Not applicable. |

|

|

3.HIGH TEMPERATURE LIGHT (thermal overload): A yellow light that comes on when an over temper- ature situation occurs. Output is disabled until the machine cools down. When cool, the light goes out and output is enabled.

4.10 AMP WIRE FEEDER CIRCUIT BREAKER: Protects 40 volt DC wire feeder power supply.

5.AUXILIARY POWER CIRCUIT BREAKER: Protects case front receptacle auxiliary supply. (10 amp on

6.LEAD CONNECTOR S2 (SENSE LEAD)

7.

8.

9.I / O CONNECTOR

10.NEGATIVE STUD

11.INTERFACE CONNECTOR S6

12.POSITIVE STUD

13.AUXILUARY OUTPUT

14.ETHERNET CONTROLS (NOT SHOWN)

FIGURE B.1

WELDER OPERATION

Making a Weld

The serviceability of a product or structure utilizing the welding programs is and must be the sole responsibili- ty of the builder/user. Many variables beyond the con- trol of The Lincoln Electric Company affect the results obtained in applying these programs. These variables include, but are not limited to, welding procedure, plate chemistry and temperature, weldment design, fabrication methods and service requirements. The available range of a welding program may not be suit- able for all applications, and the build/user is and must be solely responsible for welding program selection.

The steps for operating the Power Wave will vary depending upon the user interface of the welding sys- tem. The flexibility of the Power Wave lets the user customize operation for the best performance.

First, consider the desired welding process and the part to be welded. Choose an electrode material, diameter, shielding gas and process (GMAW, GMAW- P, SAW, etc.)