7LEARNING TO WELD7

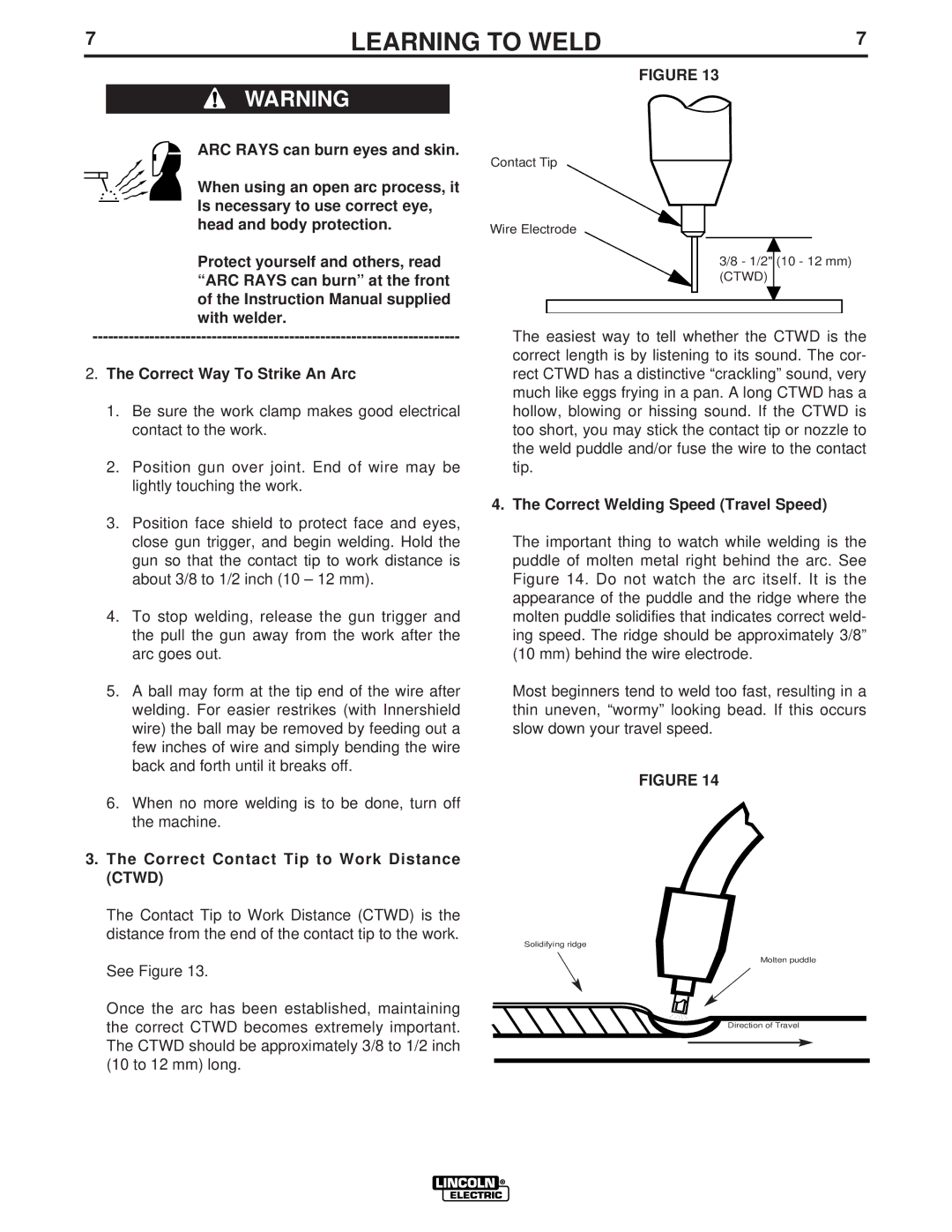

FIGURE 13

WARNING

ARC RAYS can burn eyes and skin.

When using an open arc process, it Is necessary to use correct eye, head and body protection.

Protect yourself and others, read “ARC RAYS can burn” at the front of the Instruction Manual supplied with welder.

2.The Correct Way To Strike An Arc

1.Be sure the work clamp makes good electrical contact to the work.

2.Position gun over joint. End of wire may be lightly touching the work.

3.Position face shield to protect face and eyes, close gun trigger, and begin welding. Hold the gun so that the contact tip to work distance is about 3/8 to 1/2 inch (10 – 12 mm).

4.To stop welding, release the gun trigger and the pull the gun away from the work after the arc goes out.

5.A ball may form at the tip end of the wire after welding. For easier restrikes (with Innershield wire) the ball may be removed by feeding out a few inches of wire and simply bending the wire back and forth until it breaks off.

6.When no more welding is to be done, turn off the machine.

3.The Correct Contact Tip to Work Distance (CTWD)

The Contact Tip to Work Distance (CTWD) is the distance from the end of the contact tip to the work.

See Figure 13.

Once the arc has been established, maintaining the correct CTWD becomes extremely important. The CTWD should be approximately 3/8 to 1/2 inch (10 to 12 mm) long.

Contact Tip

Wire Electrode

3/8 - 1/2" (10 - 12 mm) (CTWD)

The easiest way to tell whether the CTWD is the correct length is by listening to its sound. The cor- rect CTWD has a distinctive “crackling” sound, very much like eggs frying in a pan. A long CTWD has a hollow, blowing or hissing sound. If the CTWD is too short, you may stick the contact tip or nozzle to the weld puddle and/or fuse the wire to the contact tip.

4.The Correct Welding Speed (Travel Speed)

The important thing to watch while welding is the puddle of molten metal right behind the arc. See Figure 14. Do not watch the arc itself. It is the appearance of the puddle and the ridge where the molten puddle solidifies that indicates correct weld- ing speed. The ridge should be approximately 3/8” (10 mm) behind the wire electrode.

Most beginners tend to weld too fast, resulting in a thin uneven, “wormy” looking bead. If this occurs slow down your travel speed.

FIGURE 14

Solidifying ridge

Molten puddle

Direction of Travel