4 | LEARNING TO WELD | 4 |

|

|

|

PROCESS SELECTION

By gaining knowledge of the differences between the two processes, you will be able to select the best process for the job you have at hand. In selecting a process, you should consider:

For GMAW (MIG) Process

1.Is most of my welding performed on 16 gauge and lighter materials?

2.Can I afford the extra expense, space, and lack of portability required for gas cylinders and gas sup- ply?

3.Do I require clean,

4.Base metal must be clean.

If you have answered yes to all the above questions GMAW may be the process for you. If you have answered no to any of the above questions, then you should consider using the FCAW process.

For FCAW (Innershield) Process

1.Do I want simplicity and portability?

2.Will welding be performed outdoors or under windy conditions?

3.Do I require good all position welding capability?

4.Will most welding be performed on 16 gauge and heavier, somewhat rusty or dirty materials?

5.Weld must be cleaned prior to painting.

6.Please note that your machine may or may not be set up to handle both FCAW and GMAW welding processes. Refer to your “Operators Manual” to determine Option Accessories are required to adapt to your machine.

COMMON METALS

Most metals found around the farm, small shop or home are low carbon steel, sometimes referred to as mild steel. Typical items made with this type of steel include most sheet metal, plate, pipe and rolled shapes such as channels and angle irons. This type of steel can usually be easily welded without special pre- cautions. Some steels, however, contain higher car- bon levels or other alloys and are more difficult to weld. Basically, if a magnet sticks to the metal and you can easily cut the metal with a file, chances are good that the metal is mild steel and that you will be able to weld the material. If you plan to weld on alu- minum, special drive rolls or aluminum Welding Kits may be required or highly recommended. Consult your machines Operators Manual. Pure Argon shield- ing gas and a spool of aluminum welding wire will also be required. For further information on identifying vari- ous types of steels and other metals, and for proper procedures for welding them, we again suggest you purchase a copy of “Metals and How to Weld Them”.

Regardless of the type of metal being welded, in order to get a quality weld, it is important that the metal is free of oil, paint, rust or other contaminant’s.

JOINT TYPES AND POSITIONS

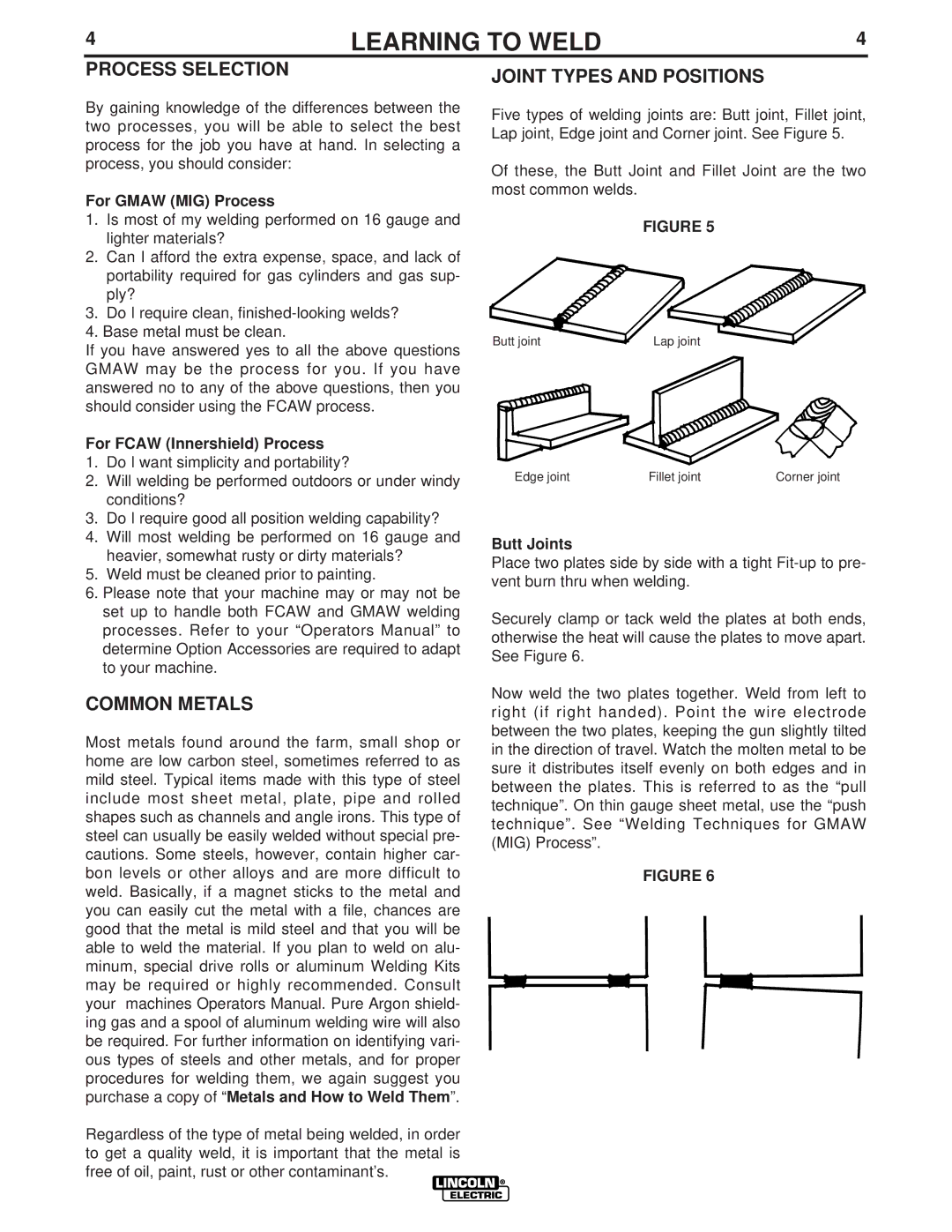

Five types of welding joints are: Butt joint, Fillet joint, Lap joint, Edge joint and Corner joint. See Figure 5.

Of these, the Butt Joint and Fillet Joint are the two most common welds.

FIGURE 5

Butt joint | Lap joint |

Edge joint | Fillet joint | Corner joint |

Butt Joints

Place two plates side by side with a tight

Securely clamp or tack weld the plates at both ends, otherwise the heat will cause the plates to move apart. See Figure 6.

Now weld the two plates together. Weld from left to right (if right handed). Point the wire electrode between the two plates, keeping the gun slightly tilted in the direction of travel. Watch the molten metal to be sure it distributes itself evenly on both edges and in between the plates. This is referred to as the “pull technique”. On thin gauge sheet metal, use the “push technique”. See “Welding Techniques for GMAW (MIG) Process”.

FIGURE 6