11 | LEARNING TO WELD | 11 |

|

|

|

TROUBLESHOOTING WELDS

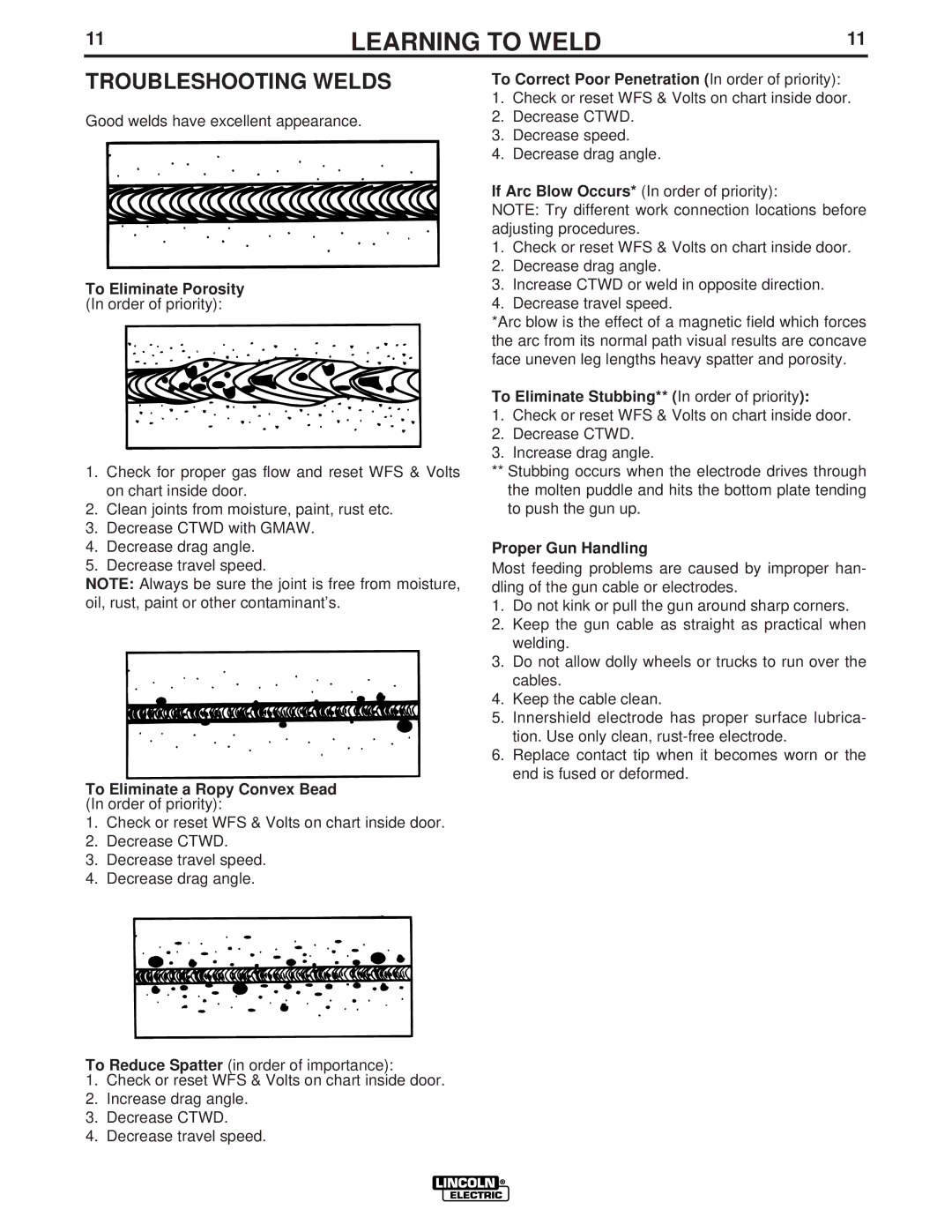

Good welds have excellent appearance.

To Eliminate Porosity (In order of priority):

1.Check for proper gas flow and reset WFS & Volts on chart inside door.

2.Clean joints from moisture, paint, rust etc.

3.Decrease CTWD with GMAW.

4.Decrease drag angle.

5.Decrease travel speed.

NOTE: Always be sure the joint is free from moisture, oil, rust, paint or other contaminant’s.

To Eliminate a Ropy Convex Bead (In order of priority):

1.Check or reset WFS & Volts on chart inside door.

2.Decrease CTWD.

3.Decrease travel speed.

4.Decrease drag angle.

To Reduce Spatter (in order of importance):

1.Check or reset WFS & Volts on chart inside door.

2.Increase drag angle.

3.Decrease CTWD.

4.Decrease travel speed.

To Correct Poor Penetration (In order of priority):

1.Check or reset WFS & Volts on chart inside door.

2.Decrease CTWD.

3.Decrease speed.

4.Decrease drag angle.

If Arc Blow Occurs* (In order of priority):

NOTE: Try different work connection locations before adjusting procedures.

1.Check or reset WFS & Volts on chart inside door.

2.Decrease drag angle.

3.Increase CTWD or weld in opposite direction.

4.Decrease travel speed.

*Arc blow is the effect of a magnetic field which forces the arc from its normal path visual results are concave face uneven leg lengths heavy spatter and porosity.

To Eliminate Stubbing** (In order of priority):

1.Check or reset WFS & Volts on chart inside door.

2.Decrease CTWD.

3.Increase drag angle.

**Stubbing occurs when the electrode drives through the molten puddle and hits the bottom plate tending to push the gun up.

Proper Gun Handling

Most feeding problems are caused by improper han- dling of the gun cable or electrodes.

1.Do not kink or pull the gun around sharp corners.

2.Keep the gun cable as straight as practical when welding.

3.Do not allow dolly wheels or trucks to run over the cables.

4.Keep the cable clean.

5.Innershield electrode has proper surface lubrica- tion. Use only clean,

6.Replace contact tip when it becomes worn or the end is fused or deformed.