9 | LEARNING TO STICK WELD | 9 |

After welding Cast Iron, protect the casting against fast cooling. Put it in a sand (or lime) box.

If sand or lime is not available, cover it with sheet metal or any other

Cast Iron Plate Preparation

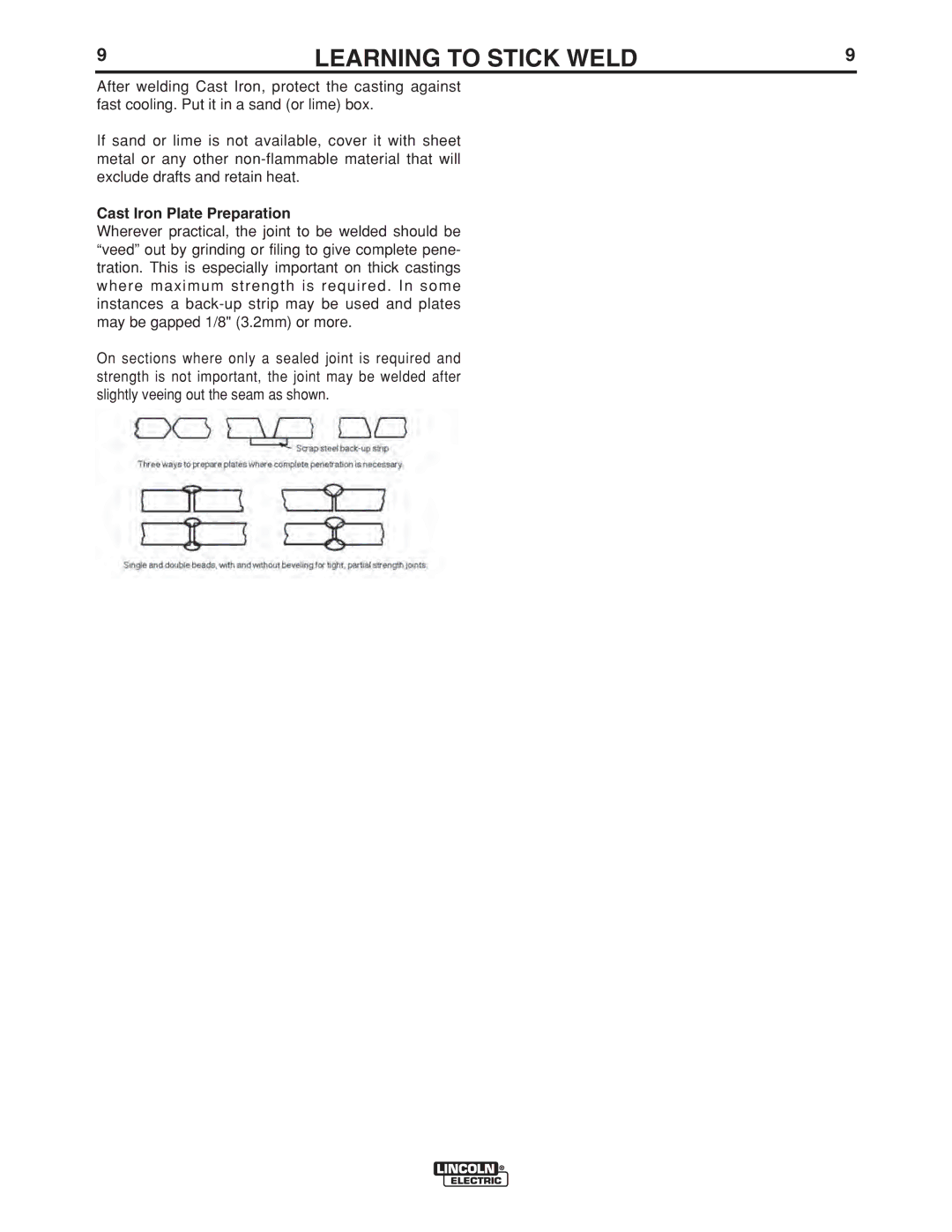

Wherever practical, the joint to be welded should be “veed” out by grinding or filing to give complete pene- tration. This is especially important on thick castings where maximum strength is required . In some instances a

On sections where only a sealed joint is required and strength is not important, the joint may be welded after slightly veeing out the seam as shown.