MAINTENANCE |

Return to Section TOC

TOC

CAUTION

Excessive pressure at the start may cause the dirt to form a plug.

Flex the cable over its entire length and again blow out the cable. Repeat this procedure until no further dirt comes out. If this has been done and feed problems are experienced, try liner replacement, and refer to the trouble shooting section on rough wire feeding.

LINER REMOVAL AND REPLACE- MENT

NOTE: Changing the liner for a different wire size requires replacement of the gas diffuser per Table D.1 to properly secure the different liner.

4.Insert a new untrimmed liner into the connector end of the cable. Be sure the liner bushing is stencilled appropriately for the wire size bing used.

5.Fully seat the liner bushing into the connector. tight- en the set screw on the brass cable connector. the gas diffuser, at this time, should not be installed onto the end of the gun tube.

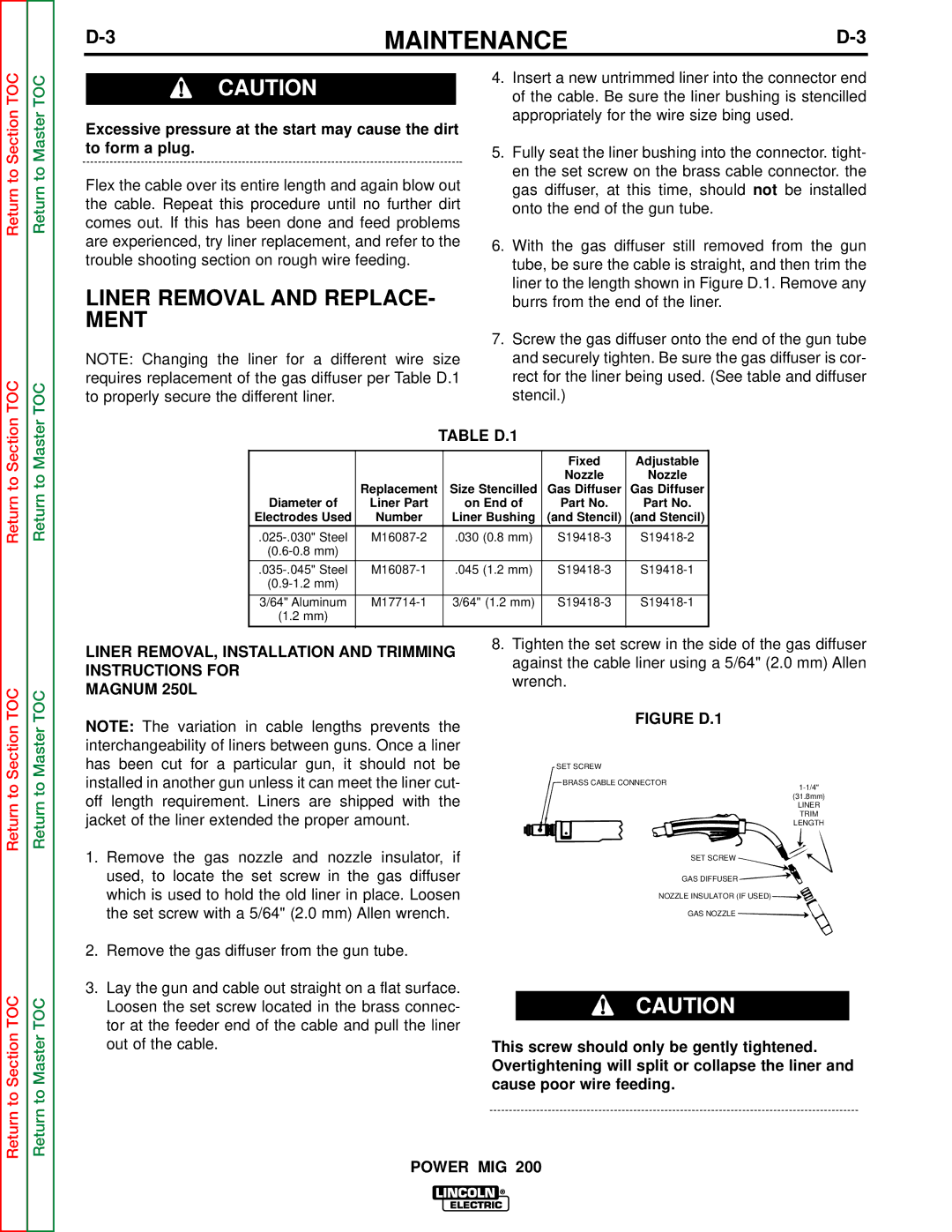

6.With the gas diffuser still removed from the gun tube, be sure the cable is straight, and then trim the liner to the length shown in Figure D.1. Remove any burrs from the end of the liner.

7.Screw the gas diffuser onto the end of the gun tube and securely tighten. Be sure the gas diffuser is cor- rect for the liner being used. (See table and diffuser stencil.)

TABLE D.1

|

|

| Fixed | Adjustable |

|

|

| Nozzle | Nozzle |

| Replacement | Size Stencilled | Gas Diffuser | Gas Diffuser |

Diameter of | Liner Part | on End of | Part No. | Part No. |

Electrodes Used | Number | Liner Bushing | (and Stencil) | (and Stencil) |

.030 (0.8 mm) | ||||

|

|

|

| |

.045 (1.2 mm) | ||||

|

|

|

| |

3/64" Aluminum | 3/64" (1.2 mm) | |||

(1.2 mm) |

|

|

|

|

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

LINER REMOVAL, INSTALLATION AND TRIMMING INSTRUCTIONS FOR

MAGNUM 250L

NOTE: The variation in cable lengths prevents the interchangeability of liners between guns. Once a liner has been cut for a particular gun, it should not be installed in another gun unless it can meet the liner cut- off length requirement. Liners are shipped with the jacket of the liner extended the proper amount.

1.Remove the gas nozzle and nozzle insulator, if used, to locate the set screw in the gas diffuser which is used to hold the old liner in place. Loosen the set screw with a 5/64" (2.0 mm) Allen wrench.

8.Tighten the set screw in the side of the gas diffuser against the cable liner using a 5/64" (2.0 mm) Allen wrench.

FIGURE D.1

SET SCREW

BRASS CABLE CONNECTOR

(31.8mm)

LINER

TRIM

LENGTH

SET SCREW

GAS DIFFUSER ![]()

NOZZLE INSULATOR (IF USED) ![]()

![]()

GAS NOZZLE ![]()

Return to Section TOC

Return to Master TOC

2.Remove the gas diffuser from the gun tube.

3.Lay the gun and cable out straight on a flat surface.

Loosen the set screw located in the brass connec- |

|

| CAUTION |

tor at the feeder end of the cable and pull the liner |

|

|

|

out of the cable. | This screw should only be gently tightened. | ||

| Overtightening will split or collapse the liner and | ||

| cause poor wire feeding. | ||