Model SLD Maintenance

Battery Maintenance

The

DC Motor Brush Replacement

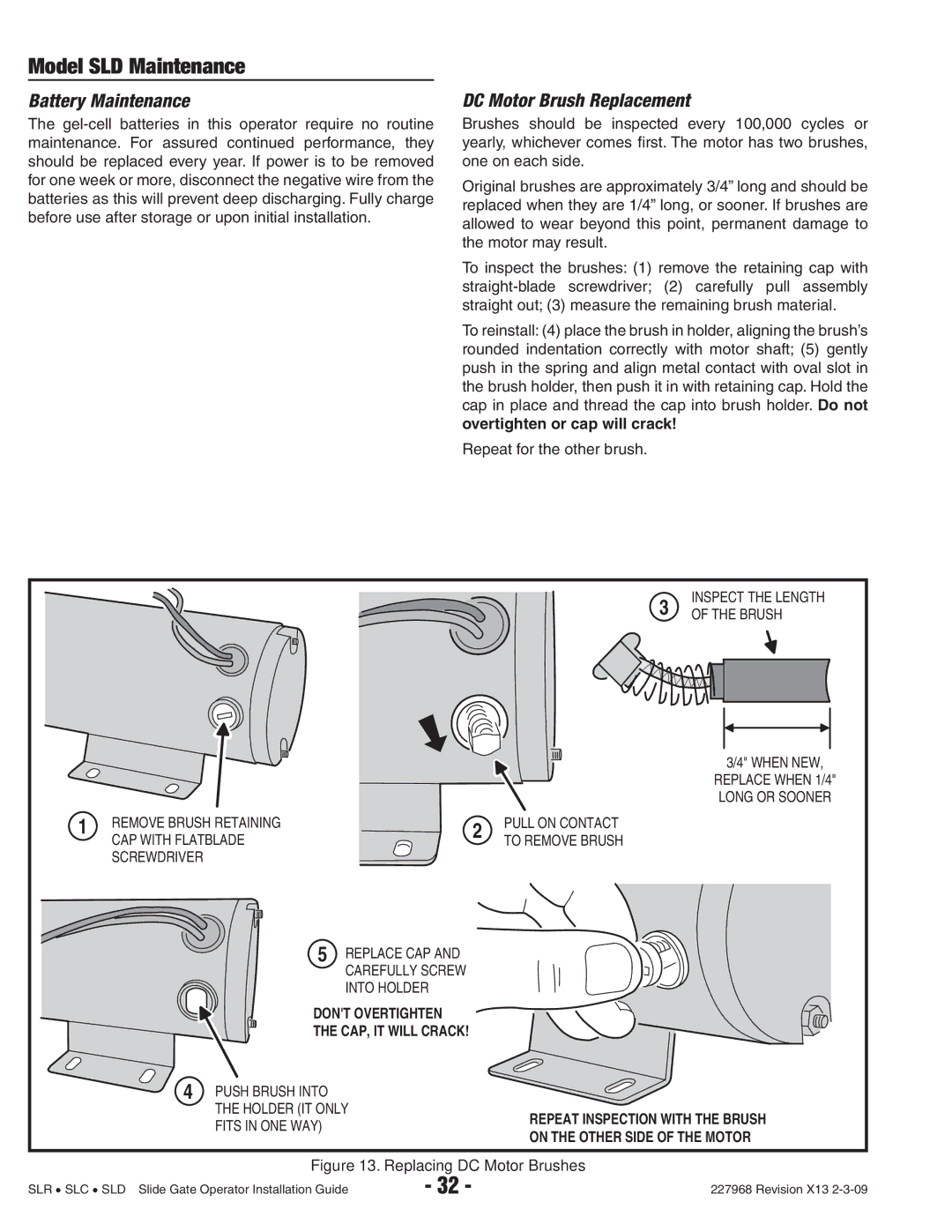

Brushes should be inspected every 100,000 cycles or yearly, whichever comes first.. The motor has two brushes, one on each side..

Original brushes are approximately 3/4” long and should be replaced when they are 1/4” long, or sooner.. If brushes are allowed to wear beyond this point, permanent damage to the motor may result..

To inspect the brushes: (1) remove the retaining cap with

To reinstall: (4) place the brush in holder, aligning the brush’s rounded indentation correctly with motor shaft; (5) gently push in the spring and align metal contact with oval slot in the brush holder, then push it in with retaining cap.. Hold the cap in place and thread the cap into brush holder.. Do not overtighten or cap will crack!

Repeat for the other brush..

3 | INSPECT THE LENGTH |

OF THE BRUSH |

3/4" WHEN NEW,

REPLACE WHEN 1/4"

LONG OR SOONER

1 | REMOVE BRUSH RETAINING | 2 | PULL ON CONTACT |

|

| ||

| CAP WITH FLATBLADE |

| TO REMOVE BRUSH |

| SCREWDRIVER |

|

|

5 REPLACE CAP AND CAREFULLY SCREW INTO HOLDER

DON'T OVERTIGHTEN

THE CAP, IT WILL CRACK!

4 PUSH BRUSH INTO THE HOLDER (IT ONLY FITS IN ONE WAY)

REPEAT INSPECTION WITH THE BRUSH ON THE OTHER SIDE OF THE MOTOR

Figure 13. Replacing DC Motor Brushes

SLR • SLC • SLD Slide Gate Operator Installation Guide | - 32 - | 227968 Revision X13 |