Service Manual

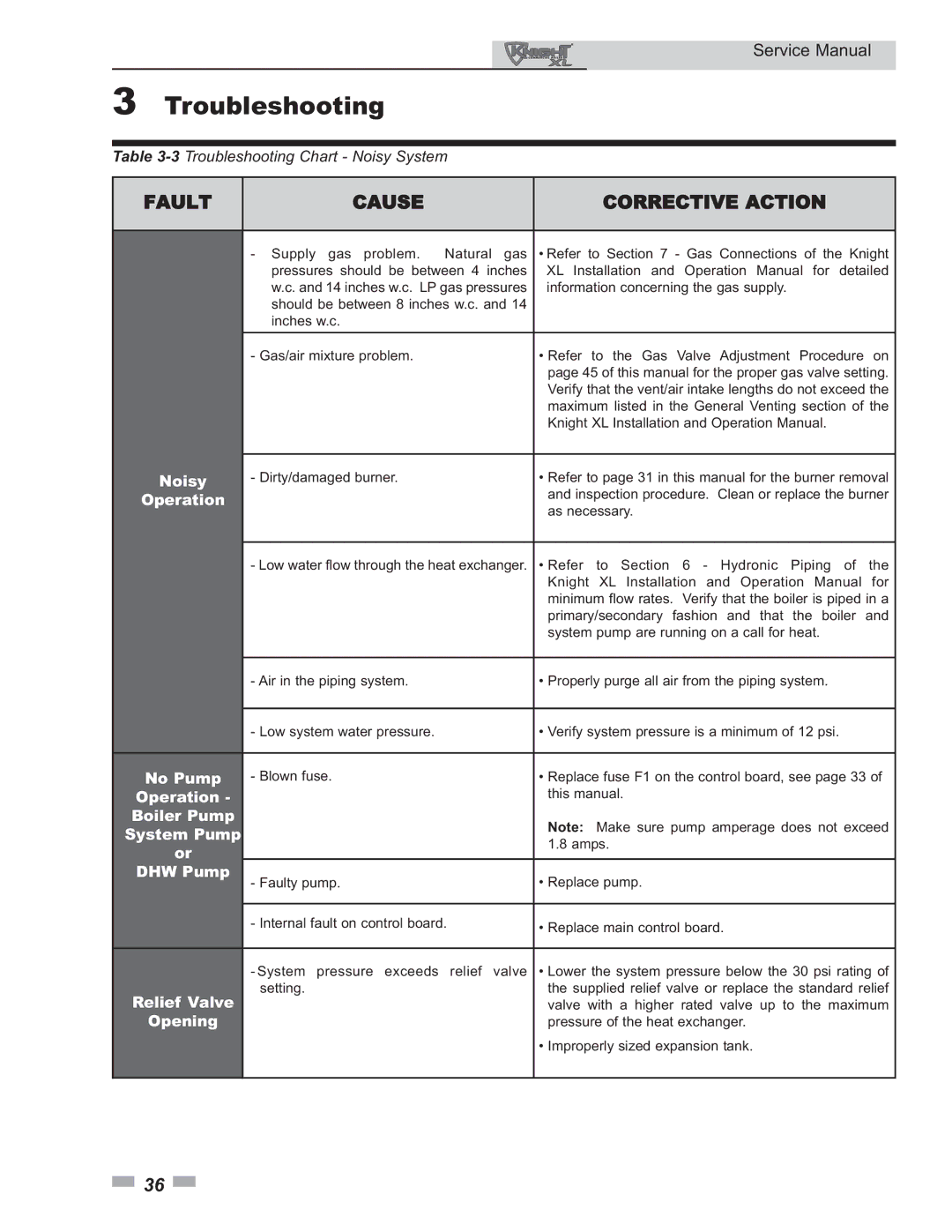

3Troubleshooting

Table

FAULT | CAUSE |

| CORRECTIVE ACTION |

|

|

|

|

| |

| - Supply gas problem. | Natural gas | • Refer to Section 7 - Gas Connections of the Knight | |

| pressures should be between 4 inches | XL Installation and Operation Manual for detailed | ||

| w.c. and 14 inches w.c. LP gas pressures | information concerning the gas supply. |

| |

| should be between 8 inches w.c. and 14 |

|

| |

| inches w.c. |

|

|

|

|

|

|

|

|

| - Gas/air mixture problem. |

| • Refer to the Gas Valve Adjustment Procedure | on |

|

|

| page 45 of this manual for the proper gas valve setting. | |

|

|

| Verify that the vent/air intake lengths do not exceed the | |

|

|

| maximum listed in the General Venting section of the | |

|

|

| Knight XL Installation and Operation Manual. |

|

Noisy |

|

|

| |

- Dirty/damaged burner. |

| • Refer to page 31 in this manual for the burner removal | ||

Operation |

|

| and inspection procedure. Clean or replace the burner | |

|

| as necessary. |

| |

|

|

|

| |

|

|

|

| |

| - Low water flow through the heat exchanger. | • Refer to Section 6 - Hydronic Piping of | the | |

|

|

| Knight XL Installation and Operation Manual for | |

|

|

| minimum flow rates. Verify that the boiler is piped in a | |

|

|

| primary/secondary fashion and that the boiler and | |

|

|

| system pump are running on a call for heat. |

|

|

|

|

|

|

| - Air in the piping system. |

| • Properly purge all air from the piping system. |

|

|

|

|

|

|

| - Low system water pressure. |

| • Verify system pressure is a minimum of 12 psi. |

|

|

|

|

| |

No Pump | - Blown fuse. |

| • Replace fuse F1 on the control board, see page 33 of | |

Operation - |

|

| this manual. |

|

Boiler Pump |

|

| Note: Make sure pump amperage does not exceed | |

System Pump |

|

| ||

|

| 1.8 amps. |

| |

or |

|

|

| |

|

|

|

| |

DHW Pump | - Faulty pump. |

| • Replace pump. |

|

|

|

| ||

|

|

|

| |

| - Internal fault on control board. | • Replace main control board. |

| |

|

|

|

| |

|

|

| ||

| - System pressure exceeds relief valve | • Lower the system pressure below the 30 psi rating of | ||

Relief Valve | setting. |

| the supplied relief valve or replace the standard relief | |

|

| valve with a higher rated valve up to the maximum | ||

Opening |

|

| pressure of the heat exchanger. |

|

|

|

| • Improperly sized expansion tank. |

|

|

|

|

|

|

![]() 36

36 ![]()