Service Manual

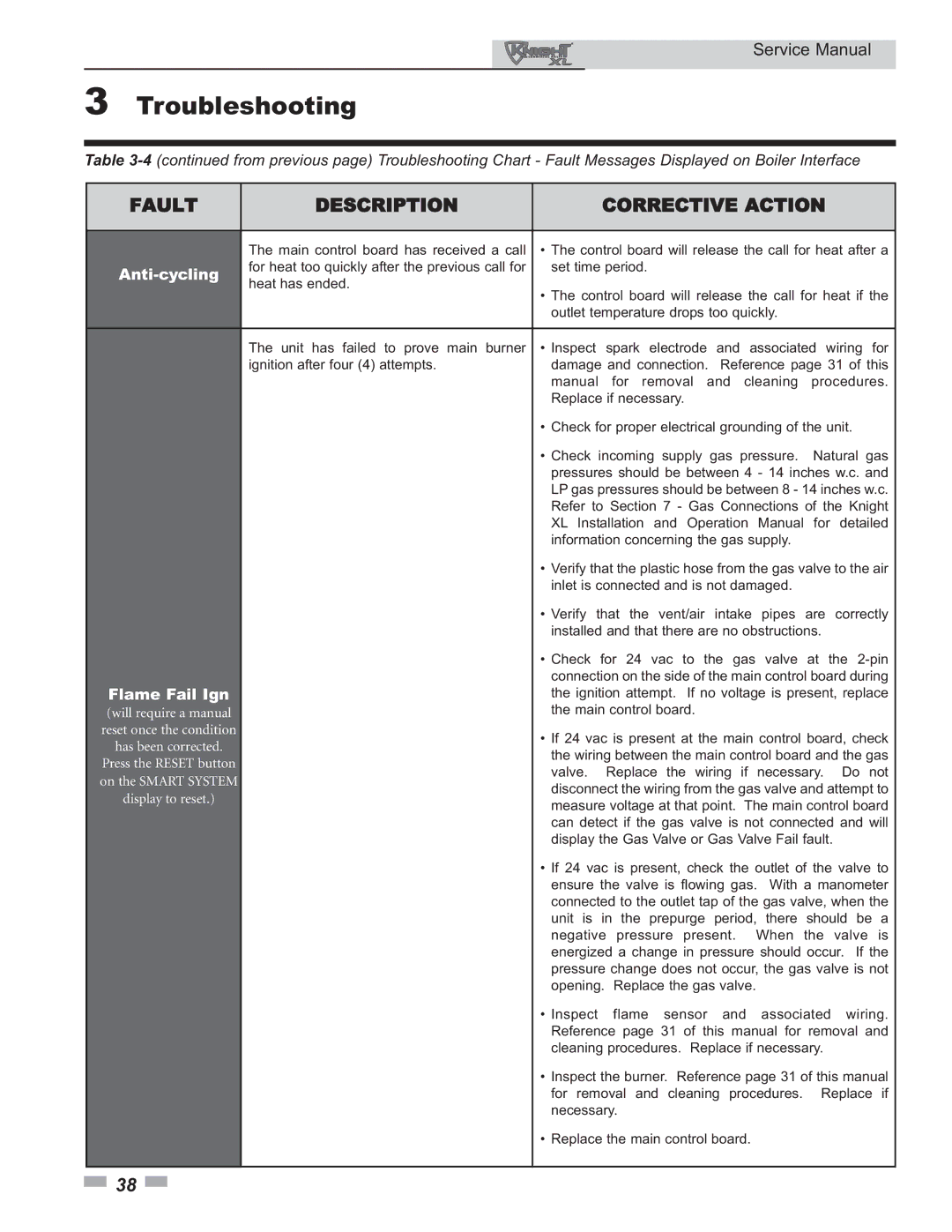

3Troubleshooting

Table

FAULT | DESCRIPTION | CORRECTIVE ACTION |

|

|

|

| The main control board has received a call | • The control board will release the call for heat after a |

| for heat too quickly after the previous call for | set time period. |

heat has ended. |

| |

| • The control board will release the call for heat if the | |

|

| |

|

| outlet temperature drops too quickly. |

|

|

|

| The unit has failed to prove main burner | • Inspect spark electrode and associated wiring for |

| ignition after four (4) attempts. | damage and connection. Reference page 31 of this |

|

| manual for removal and cleaning procedures. |

|

| Replace if necessary. |

|

| • Check for proper electrical grounding of the unit. |

|

| • Check incoming supply gas pressure. Natural gas |

|

| pressures should be between 4 - 14 inches w.c. and |

|

| LP gas pressures should be between 8 - 14 inches w.c. |

|

| Refer to Section 7 - Gas Connections of the Knight |

|

| XL Installation and Operation Manual for detailed |

|

| information concerning the gas supply. |

|

| • Verify that the plastic hose from the gas valve to the air |

|

| inlet is connected and is not damaged. |

|

| • Verify that the vent/air intake pipes are correctly |

|

| installed and that there are no obstructions. |

|

| • Check for 24 vac to the gas valve at the |

Flame Fail Ign |

| connection on the side of the main control board during |

| the ignition attempt. If no voltage is present, replace | |

(will require a manual |

| the main control board. |

reset once the condition |

| • If 24 vac is present at the main control board, check |

has been corrected. |

| |

| the wiring between the main control board and the gas | |

Press the RESET button |

| |

| valve. Replace the wiring if necessary. Do not | |

on the SMART SYSTEM |

| |

| disconnect the wiring from the gas valve and attempt to | |

display to reset.) |

| |

| measure voltage at that point. The main control board | |

|

| |

|

| can detect if the gas valve is not connected and will |

|

| display the Gas Valve or Gas Valve Fail fault. |

|

| • If 24 vac is present, check the outlet of the valve to |

|

| ensure the valve is flowing gas. With a manometer |

|

| connected to the outlet tap of the gas valve, when the |

|

| unit is in the prepurge period, there should be a |

|

| negative pressure present. When the valve is |

|

| energized a change in pressure should occur. If the |

|

| pressure change does not occur, the gas valve is not |

|

| opening. Replace the gas valve. |

|

| • Inspect flame sensor and associated wiring. |

|

| Reference page 31 of this manual for removal and |

|

| cleaning procedures. Replace if necessary. |

|

| • Inspect the burner. Reference page 31 of this manual |

|

| for removal and cleaning procedures. Replace if |

|

| necessary. |

|

| • Replace the main control board. |

|

|

|

![]() 38

38 ![]()