Service Manual

3Troubleshooting (continued)

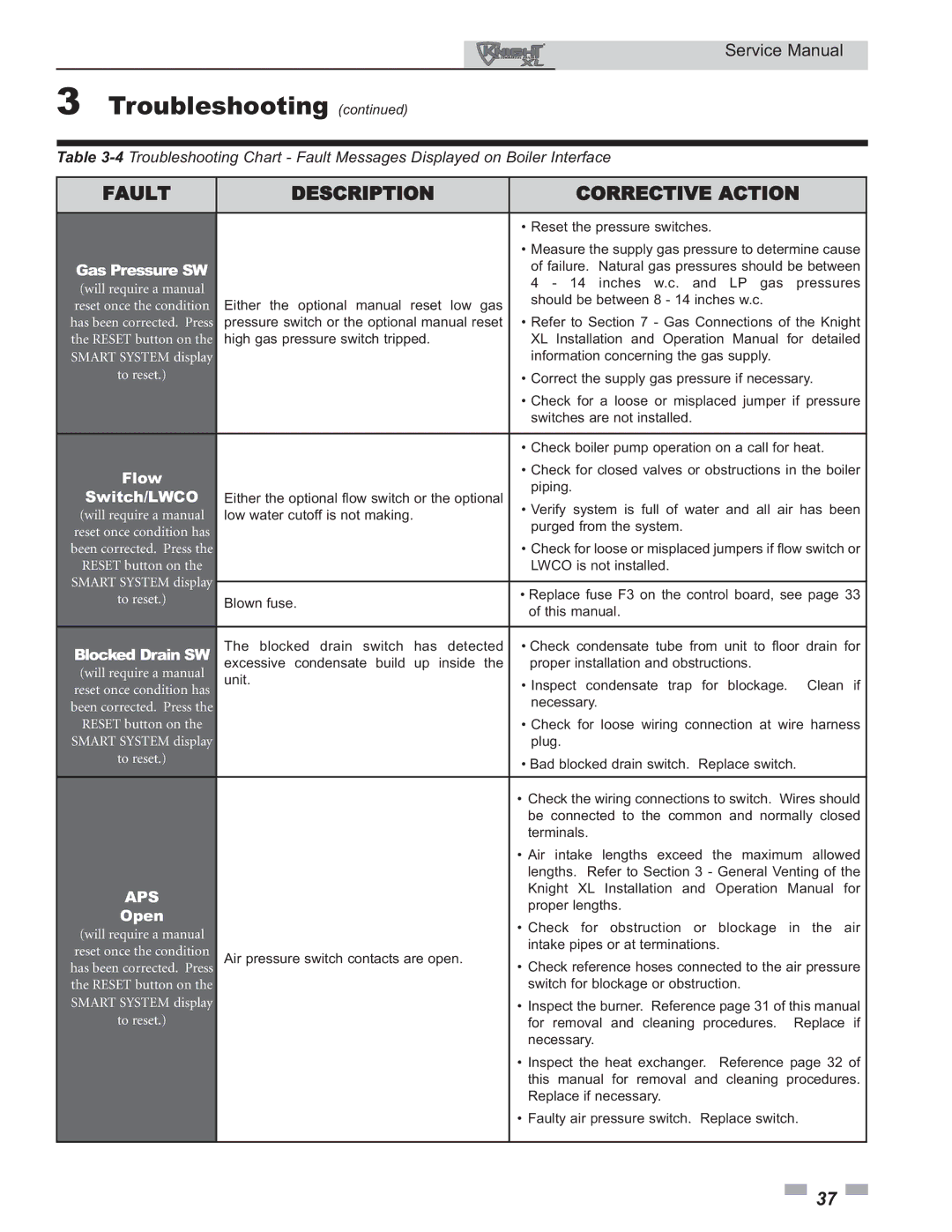

Table

FAULT | DESCRIPTION |

| CORRECTIVE ACTION |

| |||||||

|

|

|

|

|

|

| |||||

|

| • Reset the pressure switches. |

|

|

|

| |||||

|

| • Measure the supply gas pressure to determine cause | |||||||||

Gas Pressure SW |

| of failure. Natural gas pressures should be between | |||||||||

| 4 - | 14 | inches | w.c. | and | LP gas | pressures | ||||

(will require a manual |

| ||||||||||

| should be between 8 - 14 inches w.c. |

|

| ||||||||

reset once the condition | Either the optional manual reset low gas |

|

| ||||||||

|

|

|

|

|

|

|

|

| |||

has been corrected. Press | pressure switch or the optional manual reset | • Refer to Section 7 - Gas Connections of the Knight | |||||||||

the RESET button on the | high gas pressure switch tripped. | XL Installation and Operation Manual for detailed | |||||||||

SMART SYSTEM display |

| information concerning the gas supply. |

|

| |||||||

to reset.) |

| • Correct the supply gas pressure if necessary. |

| ||||||||

|

|

| |||||||||

|

| • Check for a loose or misplaced jumper if pressure | |||||||||

|

| switches are not installed. |

|

|

|

| |||||

|

|

|

| ||||||||

|

| • Check boiler pump operation on a call for heat. |

| ||||||||

Flow |

| • Check for closed valves or obstructions in the boiler | |||||||||

| piping. |

|

|

|

|

|

|

| |||

Switch/LWCO | Either the optional flow switch or the optional |

|

|

|

|

|

|

| |||

• Verify | system is | full of | water | and all air has been | |||||||

(will require a manual | low water cutoff is not making. | ||||||||||

purged from the system. |

|

|

|

| |||||||

reset once condition has |

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

| ||

been corrected. Press the |

| • Check for loose or misplaced jumpers if flow switch or | |||||||||

RESET button on the |

| LWCO is not installed. |

|

|

|

|

| ||||

SMART SYSTEM display |

|

|

|

|

|

|

|

|

|

| |

| • Replace fuse F3 on the control board, see page 33 | ||||||||||

to reset.) | Blown fuse. | ||||||||||

| of this manual. |

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| ||||

|

|

| |||||||||

Blocked Drain SW | The blocked drain switch has detected | • Check condensate tube from unit to floor drain for | |||||||||

(will require a manual | excessive condensate build up inside the | proper installation and obstructions. |

|

| |||||||

unit. | • Inspect condensate trap for blockage. | Clean | if | ||||||||

reset once condition has | |||||||||||

been corrected. Press the |

| necessary. |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| ||

RESET button on the |

| • Check for loose wiring connection at wire harness | |||||||||

SMART SYSTEM display |

| plug. |

|

|

|

|

|

|

|

| |

to reset.) |

| • Bad blocked drain switch. Replace switch. |

| ||||||||

|

|

| |||||||||

|

|

| |||||||||

|

| • Check the wiring connections to switch. Wires should | |||||||||

|

| be connected to the common and normally closed | |||||||||

|

| terminals. |

|

|

|

|

|

|

| ||

|

| • Air intake lengths exceed the maximum allowed | |||||||||

|

| lengths. Refer to Section 3 - General Venting of the | |||||||||

APS |

| Knight | XL | Installation | and | Operation | Manual | for | |||

| proper lengths. |

|

|

|

|

|

| ||||

Open |

|

|

|

|

|

|

| ||||

| • Check | for | obstruction | or | blockage | in the | air | ||||

(will require a manual |

| ||||||||||

| intake pipes or at terminations. |

|

|

| |||||||

reset once the condition |

|

|

|

| |||||||

Air pressure switch contacts are open. | • Check reference hoses connected to the air pressure | ||||||||||

has been corrected. Press |

| ||||||||||

the RESET button on the |

| switch for blockage or obstruction. |

|

| |||||||

SMART SYSTEM display |

| • Inspect the burner. Reference page 31 of this manual | |||||||||

to reset.) |

| ||||||||||

| for removal and cleaning procedures. | Replace if | |||||||||

|

| necessary. |

|

|

|

|

|

|

| ||

|

| • Inspect the heat exchanger. Reference page 32 of | |||||||||

|

| this manual for removal and cleaning procedures. | |||||||||

|

| Replace if necessary. |

|

|

|

|

| ||||

|

| • Faulty air pressure switch. Replace switch. |

| ||||||||

|

|

|

|

|

|

|

|

|

|

| |

37