LX-300 Maintenance

Overview | 23 |

Recommended Schedule | 23 |

Inspection and Maintenance Procedure | 23 |

Operational Testing | 24 |

Dust, heat, humidity and power surges are the most significant dangers to the system and its components. For best performance, the Matrix3 should be operated in a cool,

Overview

Skills Required

Visual inspection of hardware; tightening of connectors;

Required Tools and Components

•#2 Philips screwdriver.

•Soft cloth and glass cleaner.

Recommended Schedule

In most environments, a monthly inspection will be adequate.

Where conditions allow for extreme temperatures, humidity or dust infiltration; or where there is a possibility of water leakage; or where the system may be subjected to vibration, we recommend a weekly or even daily inspection.

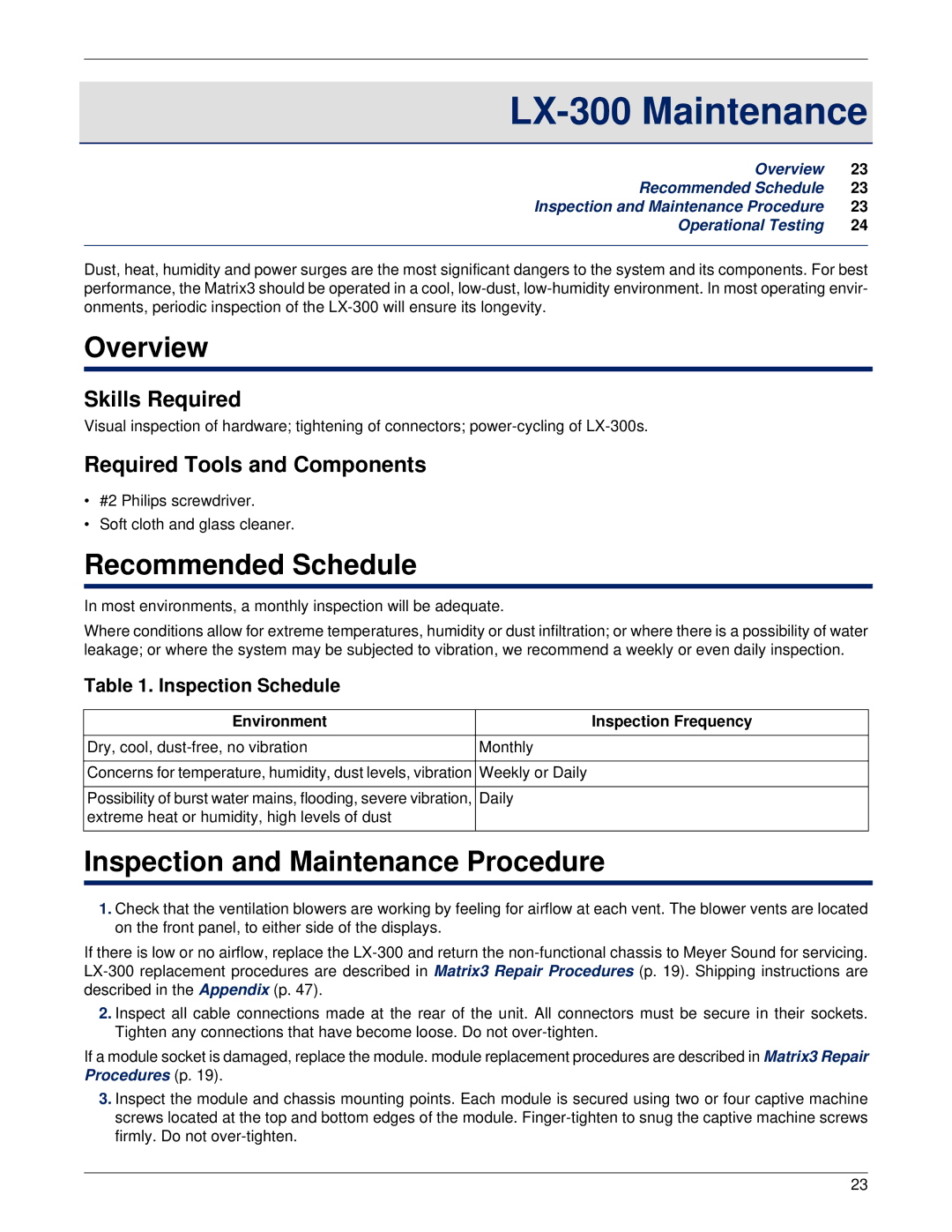

Table 1. Inspection Schedule

Environment | Inspection Frequency |

Dry, cool, | Monthly |

Concerns for temperature, humidity, dust levels, vibration ![]() Weekly or Daily

Weekly or Daily

Possibility of burst water mains, flooding, severe vibration, Daily extreme heat or humidity, high levels of dust

Inspection and Maintenance Procedure

1.Check that the ventilation blowers are working by feeling for airflow at each vent. The blower vents are located on the front panel, to either side of the displays.

If there is low or no airflow, replace the

2.Inspect all cable connections made at the rear of the unit. All connectors must be secure in their sockets. Tighten any connections that have become loose. Do not

If a module socket is damaged, replace the module. module replacement procedures are described in Matrix3 Repair Procedures (p. 19).

3.Inspect the module and chassis mounting points. Each module is secured using two or four captive machine screws located at the top and bottom edges of the module.

23