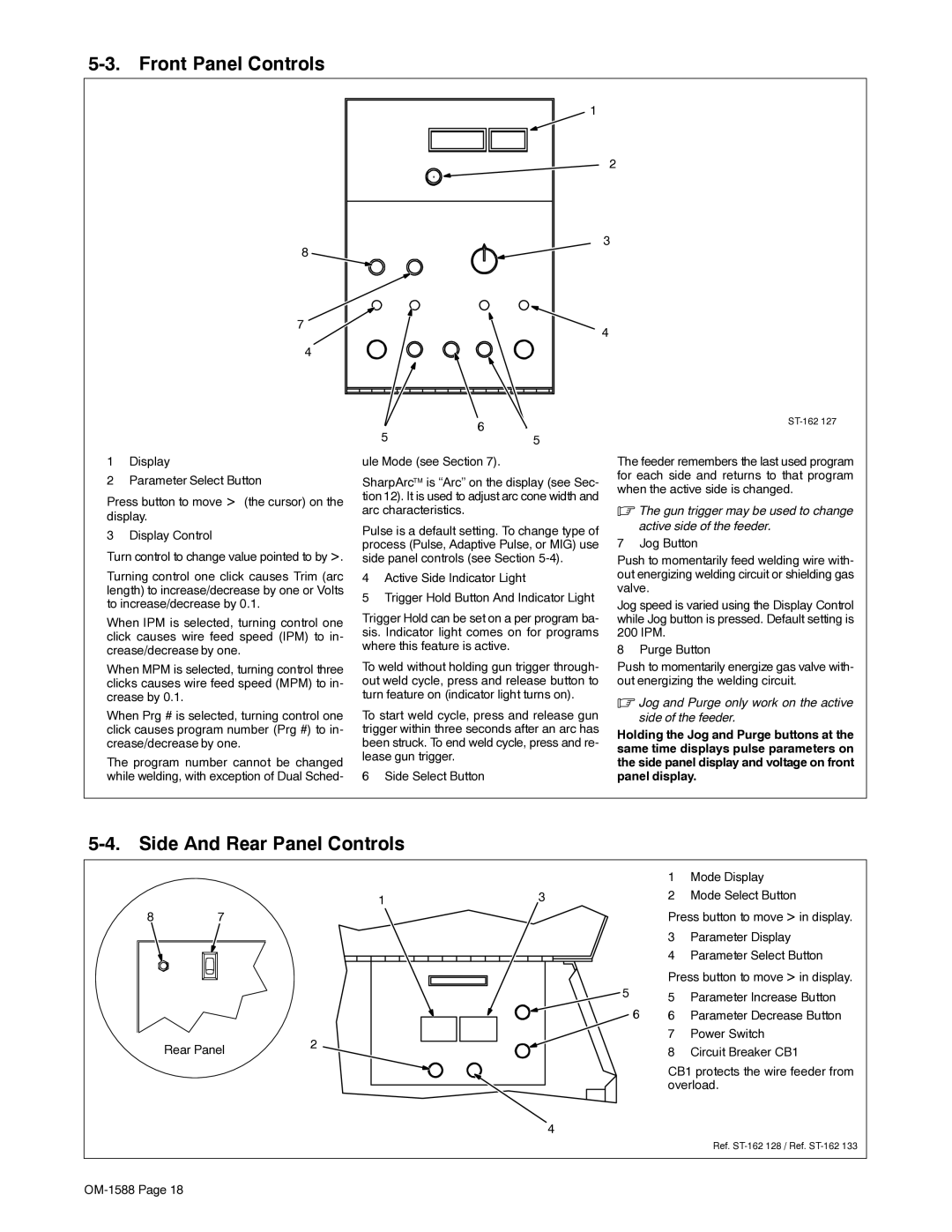

5-3. Front Panel Controls

1

8

2

3

7

4

4

| 6 | ||

5 | 5 | ||

|

1Display

2Parameter Select Button

Press button to move > (the cursor) on the display.

3 Display Control

Turn control to change value pointed to by >.

Turning control one click causes Trim (arc length) to increase/decrease by one or Volts to increase/decrease by 0.1.

When IPM is selected, turning control one click causes wire feed speed (IPM) to in- crease/decrease by one.

When MPM is selected, turning control three clicks causes wire feed speed (MPM) to in- crease by 0.1.

When Prg # is selected, turning control one click causes program number (Prg #) to in- crease/decrease by one.

The program number cannot be changed while welding, with exception of Dual Sched-

ule Mode (see Section 7).

SharpArc™ is “Arc” on the display (see Sec- tion12). It is used to adjust arc cone width and arc characteristics.

Pulse is a default setting. To change type of process (Pulse, Adaptive Pulse, or MIG) use side panel controls (see Section

4Active Side Indicator Light

5Trigger Hold Button And Indicator Light

Trigger Hold can be set on a per program ba- sis. Indicator light comes on for programs where this feature is active.

To weld without holding gun trigger through- out weld cycle, press and release button to turn feature on (indicator light turns on).

To start weld cycle, press and release gun trigger within three seconds after an arc has been struck. To end weld cycle, press and re- lease gun trigger.

6 Side Select Button

The feeder remembers the last used program for each side and returns to that program when the active side is changed.

.The gun trigger may be used to change active side of the feeder.

7 Jog Button

Push to momentarily feed welding wire with- out energizing welding circuit or shielding gas valve.

Jog speed is varied using the Display Control while Jog button is pressed. Default setting is 200 IPM.

8 Purge Button

Push to momentarily energize gas valve with- out energizing the welding circuit.

.Jog and Purge only work on the active side of the feeder.

Holding the Jog and Purge buttons at the same time displays pulse parameters on the side panel display and voltage on front panel display.

5-4. Side And Rear Panel Controls

13

8 7

5

6

Rear Panel | 2 |

|

4

1Mode Display

2Mode Select Button

Press button to move > in display.

3Parameter Display

4Parameter Select Button

Press button to move > in display.

5Parameter Increase Button

6Parameter Decrease Button

7Power Switch

8Circuit Breaker CB1

CB1 protects the wire feeder from overload.

Ref.