.A complete Parts List is available at www.MillerWelds.com

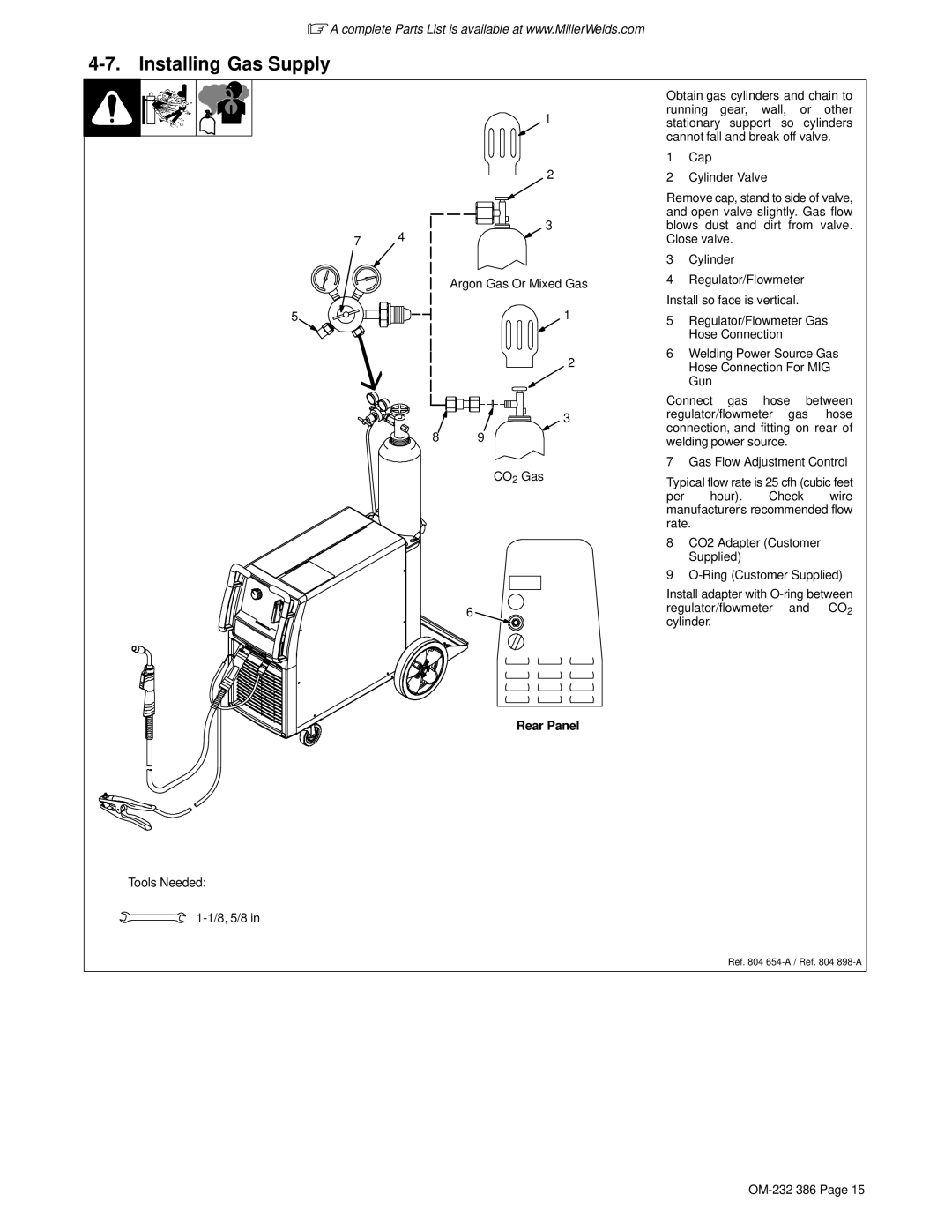

4-7. Installing Gas Supply

1

2

3

7 4

Argon Gas Or Mixed Gas

5 | 1 |

2

3

8 9

CO2 Gas

6 ![]()

Obtain gas cylinders and chain to running gear, wall, or other stationary support so cylinders cannot fall and break off valve.

1Cap

2Cylinder Valve

Remove cap, stand to side of valve, and open valve slightly. Gas flow blows dust and dirt from valve. Close valve.

3Cylinder

4Regulator/Flowmeter

Install so face is vertical.

5Regulator/Flowmeter Gas Hose Connection

6Welding Power Source Gas Hose Connection For MIG Gun

Connect gas hose between regulator/flowmeter gas hose connection, and fitting on rear of welding power source.

7 Gas Flow Adjustment Control

Typical flow rate is 25 cfh (cubic feet

per hour). Check wire manufacturer’s recommended flow rate.

8CO2 Adapter (Customer Supplied)

9

Install adapter with

Rear Panel

Tools Needed:

1-1/8, 5/8 in

Ref. 804