.A complete Parts List is available at www.MillerWelds.com

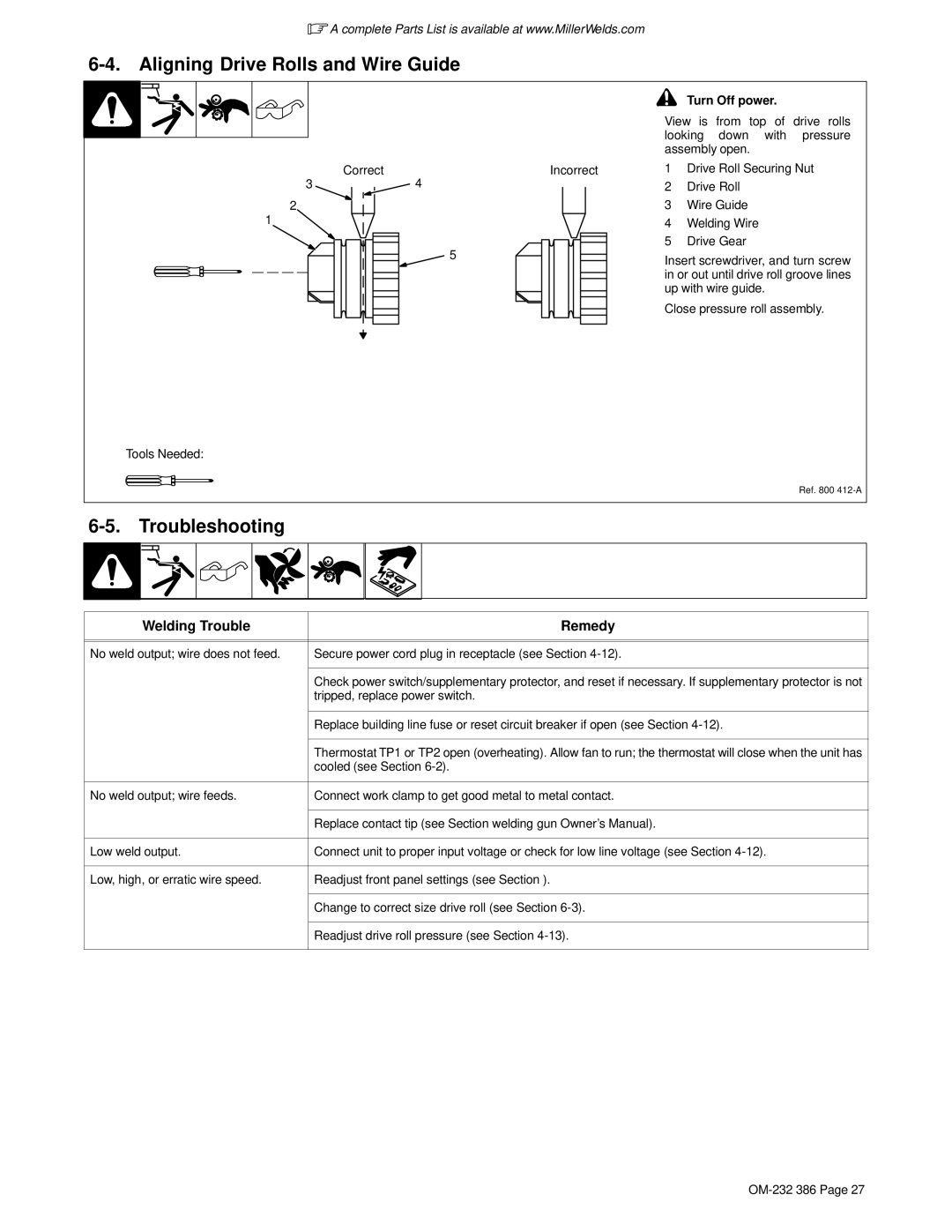

6-4. Aligning Drive Rolls and Wire Guide

! Turn Off power.

|

|

| View is from top of drive rolls | |

|

|

| looking down with pressure | |

|

|

| assembly open. | |

| Correct | Incorrect | 1 | Drive Roll Securing Nut |

3 | 4 |

| 2 | Drive Roll |

2 |

|

| 3 | Wire Guide |

1 |

|

| 4 | Welding Wire |

|

| 5 | 5 | Drive Gear |

|

| Insert screwdriver, and turn screw | ||

|

|

| ||

in or out until drive roll groove lines up with wire guide.

Close pressure roll assembly.

Tools Needed:

Ref. 800

6-5. Troubleshooting

|

|

|

|

|

|

|

|

|

|

| Welding Trouble |

|

| Remedy |

|

| |||

|

| |||

No weld output; wire does not feed. | Secure power cord plug in receptacle (see Section | |||

|

|

| ||

|

| Check power switch/supplementary protector, and reset if necessary. If supplementary protector is not | ||

|

| tripped, replace power switch. | ||

|

|

| ||

|

| Replace building line fuse or reset circuit breaker if open (see Section | ||

|

|

| ||

|

| Thermostat TP1 or TP2 open (overheating). Allow fan to run; the thermostat will close when the unit has | ||

|

| cooled (see Section | ||

|

| |||

No weld output; wire feeds. | Connect work clamp to get good metal to metal contact. | |||

|

|

| ||

|

| Replace contact tip (see Section welding gun Owner’s Manual). | ||

|

| |||

Low weld output. | Connect unit to proper input voltage or check for low line voltage (see Section | |||

|

| |||

Low, high, or erratic wire speed. | Readjust front panel settings (see Section ). | |||

|

|

| ||

|

| Change to correct size drive roll (see Section | ||

|

|

| ||

|

| Readjust drive roll pressure (see Section | ||

|

|

|

|

|