.A complete Parts List is available at www.MillerWelds.com

SECTION 6 − MAINTENANCE &TROUBLESHOOTING

6-1. Routine Maintenance

! | Disconnect power | .Maintain more often |

| before maintaining. | during severe conditions. |

n = Check | Z = Change | ~ = Clean | l = Replace |

* To be done by Factory Authorized Service Agent |

| ||

Every

3 Months

| l Unreadable Labels | ~ Weld Terminals | nl Weld Cables |

Every |

|

|

|

6 | OR |

|

|

Months |

|

| |

|

|

| |

| ~ Inside Unit | n Apply Light Coat Of Oil |

|

|

| Or Grease To Drive Motor |

|

|

| Shaft |

|

Reference

6-2. Unit Overload

Thermostats TP1 in rectifier SR1 and TP2 in stabilizer Z1 protect the unit from damage due to overheating. If TP1 and/or TP2 opens welding output will shut off, and the Over Temp light will turn on. Wait until Over Temp light turns off before trying to weld.

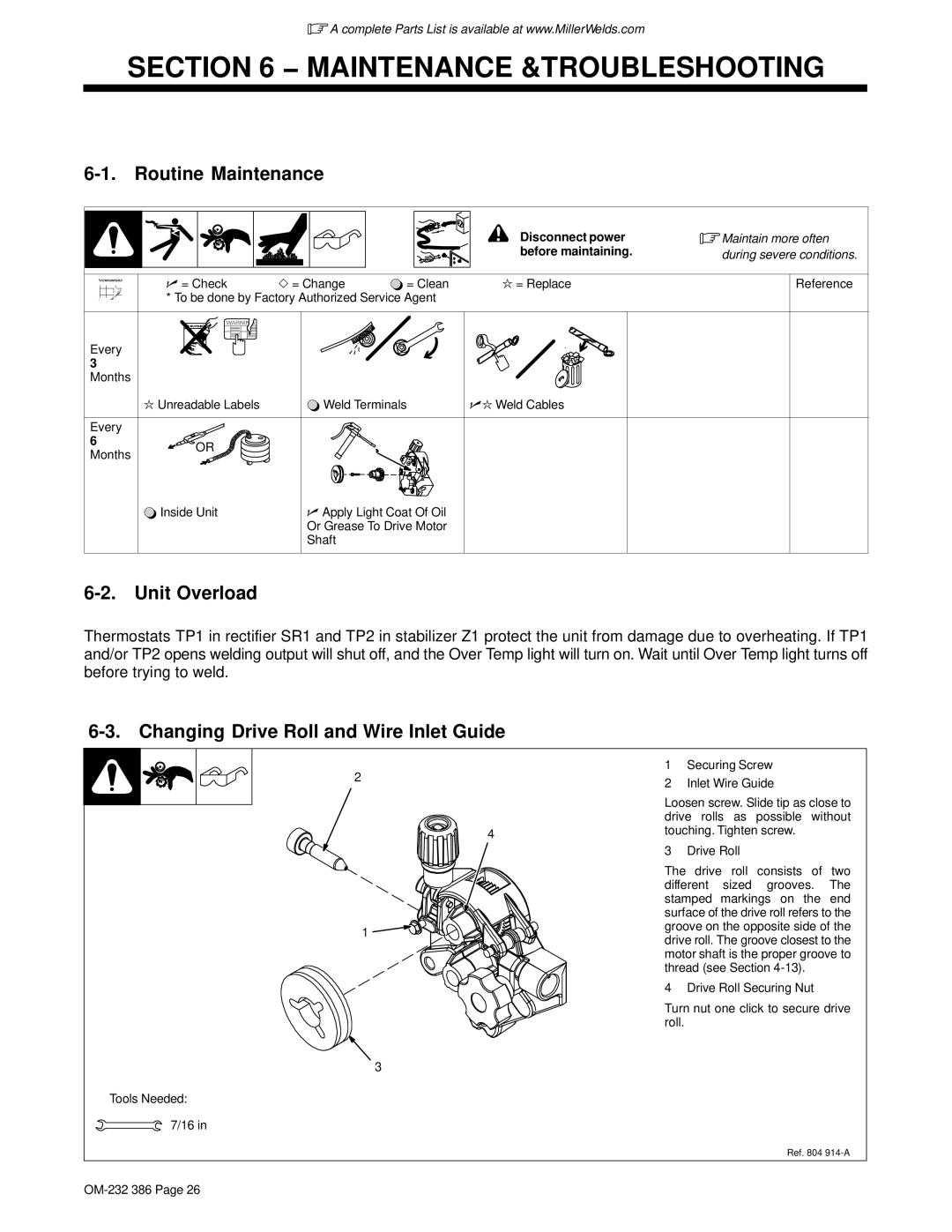

6-3. Changing Drive Roll and Wire Inlet Guide

2 |

|

| 1 | Securing Screw |

|

| 2 | Inlet Wire Guide | |

|

|

| ||

|

|

| Loosen screw. Slide tip as close to | |

|

|

| drive rolls as possible without | |

|

| 4 | touching. Tighten screw. | |

|

|

|

| |

|

|

| 3 | Drive Roll |

|

|

| The drive roll consists of two | |

|

|

| different sized grooves. The | |

|

|

| stamped markings on the end | |

|

|

| surface of the drive roll refers to the | |

| 1 |

| groove on the opposite side of the | |

|

| drive roll. The groove closest to the | ||

|

|

| ||

|

|

| motor shaft is the proper groove to | |

|

|

| thread (see Section | |

|

|

| 4 Drive Roll Securing Nut | |

|

|

| Turn nut one click to secure drive | |

|

|

| roll. |

|

|

| 3 |

|

|

Tools Needed: 7/16 in

Ref. 804