.A complete Parts List is available at www.MillerWelds.com

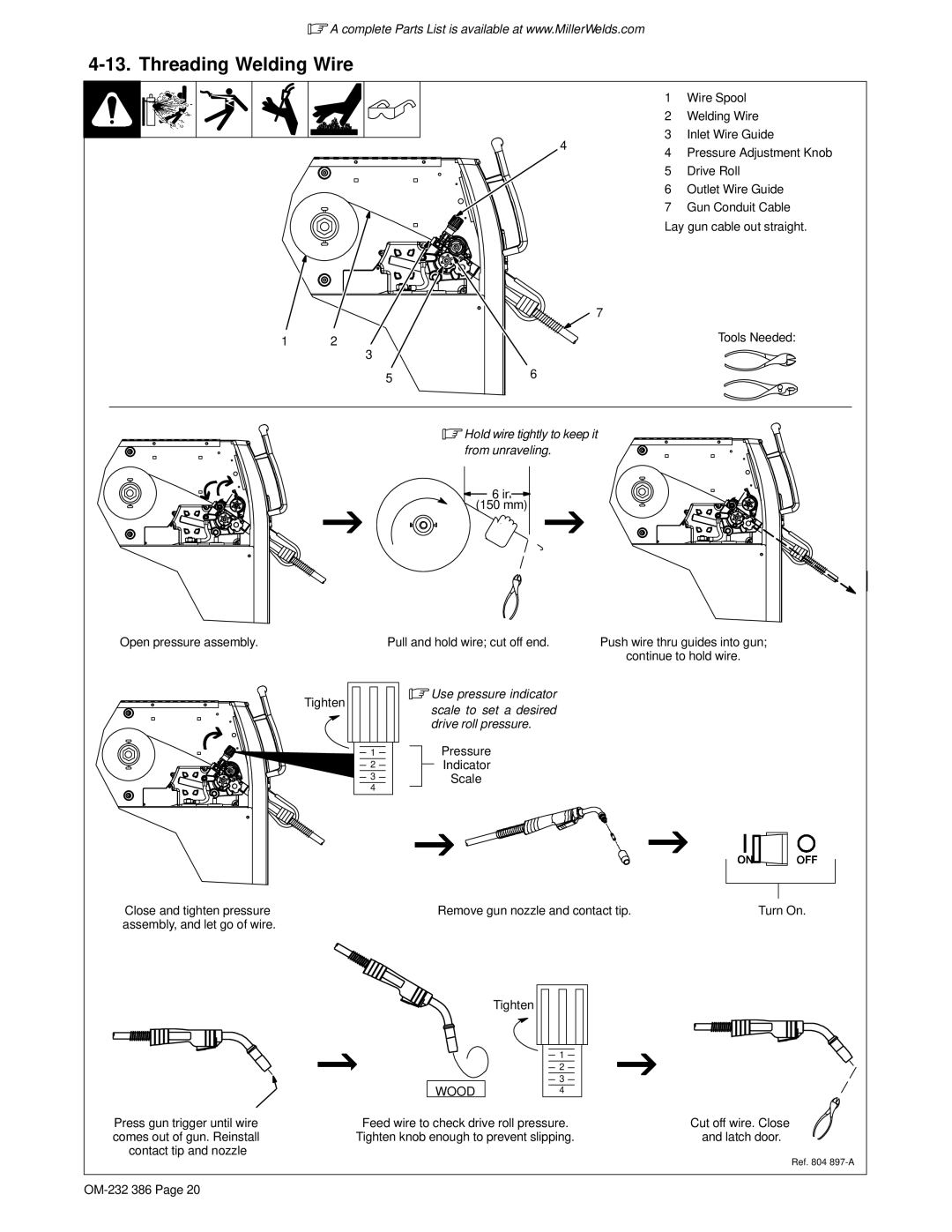

4-13. Threading Welding Wire

4

1Wire Spool

2Welding Wire

3Inlet Wire Guide

4 Pressure Adjustment Knob

5 Drive Roll

6 Outlet Wire Guide

7 Gun Conduit Cable Lay gun cable out straight.

1 2

3

56

7

Tools Needed:

.Hold wire tightly to keep it from unraveling.

![]() 6 in

6 in![]() (150 mm)

(150 mm)

Open pressure assembly.

Tighten

Pull and hold wire; cut off end. | Push wire thru guides into gun; |

| continue to hold wire. |

.Use pressure indicator scale to set a desired drive roll pressure.

1Pressure

| 2 |

|

|

|

|

| Indicator | |

|

|

|

|

|

| |||

| 3 |

|

|

|

|

|

| Scale |

|

|

|

|

|

|

| ||

4 |

|

|

|

|

|

|

| |

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Close and tighten pressure assembly, and let go of wire.

Press gun trigger until wire comes out of gun. Reinstall contact tip and nozzle

Remove gun nozzle and contact tip. | Turn On. |

Tighten

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

| 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

WOOD |

|

| 3 |

|

|

|

|

|

| |

|

|

|

|

|

|

| ||||

| 4 |

|

|

|

|

|

| |||

Feed wire to check drive roll pressure. |

| Cut off wire. Close | ||||||||

Tighten knob enough to prevent slipping. |

| and latch door. | ||||||||

Ref. 804