Tools Needed:

3/4 in

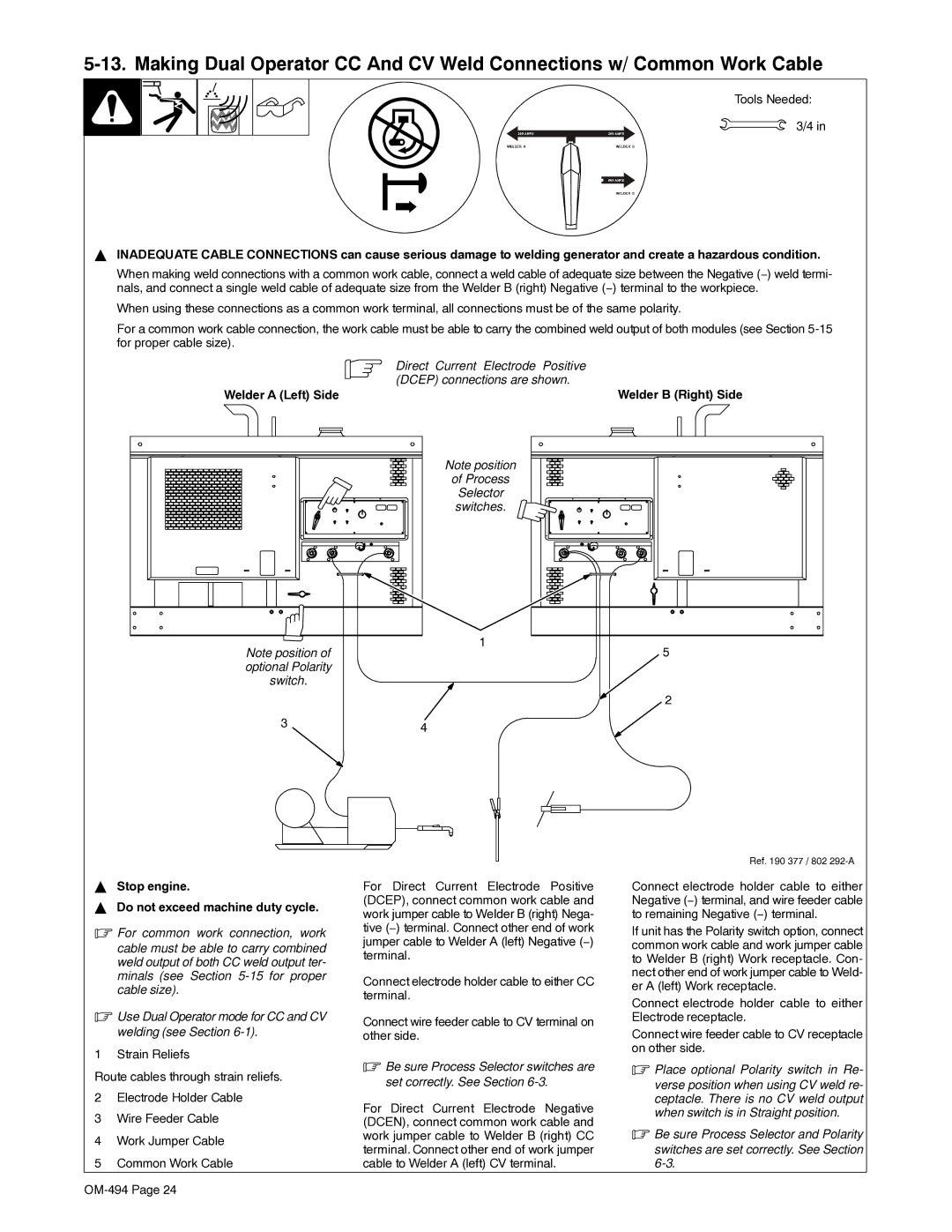

YINADEQUATE CABLE CONNECTIONS can cause serious damage to welding generator and create a hazardous condition.

When making weld connections with a common work cable, connect a weld cable of adequate size between the Negative (−) weld termi- nals, and connect a single weld cable of adequate size from the Welder B (right) Negative (−) terminal to the workpiece.

When using these connections as a common work terminal, all connections must be of the same polarity.

For a common work cable connection, the work cable must be able to carry the combined weld output of both modules (see Section

Direct Current | Electrode Positive |

(DCEP) connections are shown. | |

Welder A (Left) Side | Welder B (Right) Side |

Note position

of Process

Selector switches.

Note position of | 1 | 5 |

| ||

optional Polarity |

|

|

switch. |

|

|

|

| 2 |

3 | 4 |

|

|

|

YStop engine.

YDo not exceed machine duty cycle.

.For common work connection, work

cable must be able to carry combined weld output of both CC weld output ter- minals (see Section

.Use Dual Operator mode for CC and CV welding (see Section

1 Strain Reliefs

Route cables through strain reliefs.

2Electrode Holder Cable

3Wire Feeder Cable

4Work Jumper Cable

5Common Work Cable

For Direct Current Electrode Positive (DCEP), connect common work cable and work jumper cable to Welder B (right) Nega- tive (−) terminal. Connect other end of work jumper cable to Welder A (left) Negative (−) terminal.

Connect electrode holder cable to either CC terminal.

Connect wire feeder cable to CV terminal on other side.

.Be sure Process Selector switches are set correctly. See Section

For Direct Current Electrode Negative (DCEN), connect common work cable and work jumper cable to Welder B (right) CC terminal. Connect other end of work jumper cable to Welder A (left) CV terminal.

Ref. 190 377 / 802

Connect electrode holder cable to either Negative (−) terminal, and wire feeder cable to remaining Negative (−) terminal.

If unit has the Polarity switch option, connect common work cable and work jumper cable to Welder B (right) Work receptacle. Con- nect other end of work jumper cable to Weld- er A (left) Work receptacle.

Connect electrode holder cable to either Electrode receptacle.

Connect wire feeder cable to CV receptacle on other side.

.Place optional Polarity switch in Re-

verse position when using CV weld re- ceptacle. There is no CV weld output when switch is in Straight position.

.Be sure Process Selector and Polarity