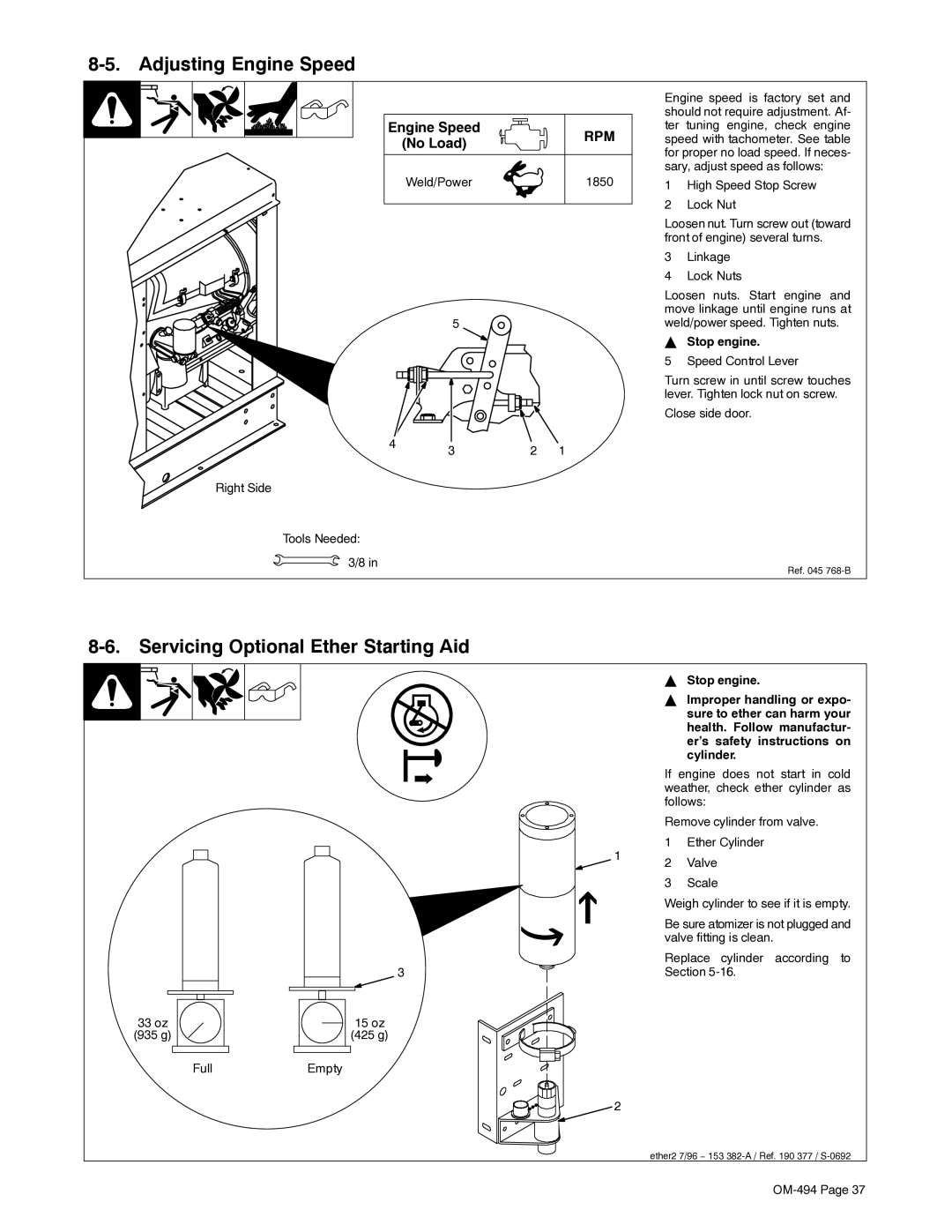

8-5. Adjusting Engine Speed

Engine Speed | RPM | |

(No Load) | ||

| ||

Weld/Power | 1850 |

5

4 | 3 | 2 | 1 |

|

Right Side

Tools Needed: 3/8 in

Engine speed is factory set and should not require adjustment. Af- ter tuning engine, check engine speed with tachometer. See table for proper no load speed. If neces- sary, adjust speed as follows:

1High Speed Stop Screw

2Lock Nut

Loosen nut. Turn screw out (toward front of engine) several turns.

3Linkage

4Lock Nuts

Loosen nuts. Start engine and move linkage until engine runs at weld/power speed. Tighten nuts.

YStop engine.

5 Speed Control Lever

Turn screw in until screw touches lever. Tighten lock nut on screw.

Close side door.

Ref. 045

8-6. Servicing Optional Ether Starting Aid

3

33 oz | 15 oz |

(935 g) | (425 g) |

Full | Empty |

| Y | Stop engine. | |

| Y Improper handling or expo- | ||

|

| sure to ether can harm your | |

|

| health. Follow manufactur- | |

|

| er’s safety instructions on | |

|

| cylinder. | |

| If engine does not start in cold | ||

| weather, check ether cylinder as | ||

| follows: | ||

| Remove cylinder from valve. | ||

1 | 1 | Ether Cylinder | |

2 | Valve | ||

| |||

| 3 | Scale | |

| Weigh cylinder to see if it is empty. | ||

Be sure atomizer is not plugged and valve fitting is clean.

Replace cylinder according to Section

2

ether2 7/96 − 153