SECTION 5 − INSTALLATION

NOTE

When facing the front panel, the Welder B controls and weld terminals are on the right and the Welder A controls and weld terminals are on the left.

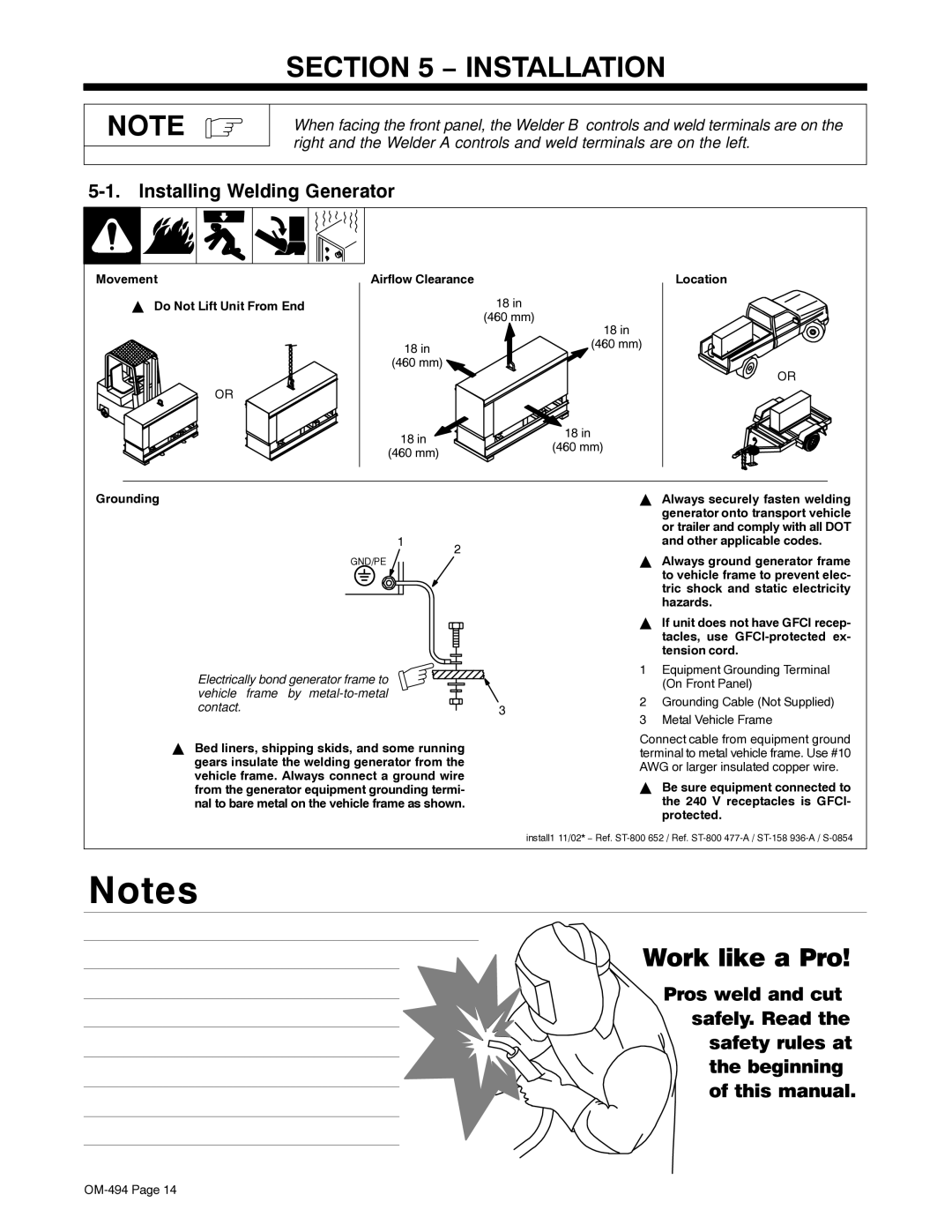

5-1. Installing Welding Generator

Movement

YDo Not Lift Unit From End

OR

Airflow Clearance

18in

(460 mm)

| 18 in | |

18 in | (460 mm) | |

| ||

(460 mm) |

| |

18 in | 18 in | |

(460 mm) | ||

(460 mm) | ||

|

Location

OR

Grounding |

|

| Y Always securely fasten welding | |

|

|

|

| generator onto transport vehicle |

|

|

|

| or trailer and comply with all DOT |

1 | 2 |

|

| and other applicable codes. |

GND/PE |

| Y | Always ground generator frame | |

|

| |||

|

|

|

| to vehicle frame to prevent elec- |

|

|

|

| tric shock and static electricity |

|

|

|

| hazards. |

|

|

| Y If unit does not have GFCI recep- | |

|

|

|

| tacles, use |

|

|

|

| tension cord. |

Electrically bond generator frame to |

|

| 1 | Equipment Grounding Terminal |

|

|

| (On Front Panel) | |

vehicle frame by |

|

|

| |

|

| 2 | Grounding Cable (Not Supplied) | |

contact. |

| 3 | ||

| 3 | Metal Vehicle Frame | ||

|

|

| ||

Y Bed liners, shipping skids, and some running |

| Connect cable from equipment ground | ||

| terminal to metal vehicle frame. Use #10 | |||

gears insulate the welding generator from the |

| |||

| AWG or larger insulated copper wire. | |||

vehicle frame. Always connect a ground wire |

| |||

|

| Be sure equipment connected to | ||

from the generator equipment grounding termi- |

| Y | ||

nal to bare metal on the vehicle frame as shown. |

|

| the 240 V receptacles is GFCI- | |

|

|

|

| protected. |

install1 11/02* − Ref.

Notes

Work like a Pro!

Pros weld and cut safely. Read the safety rules at the beginning of this manual.