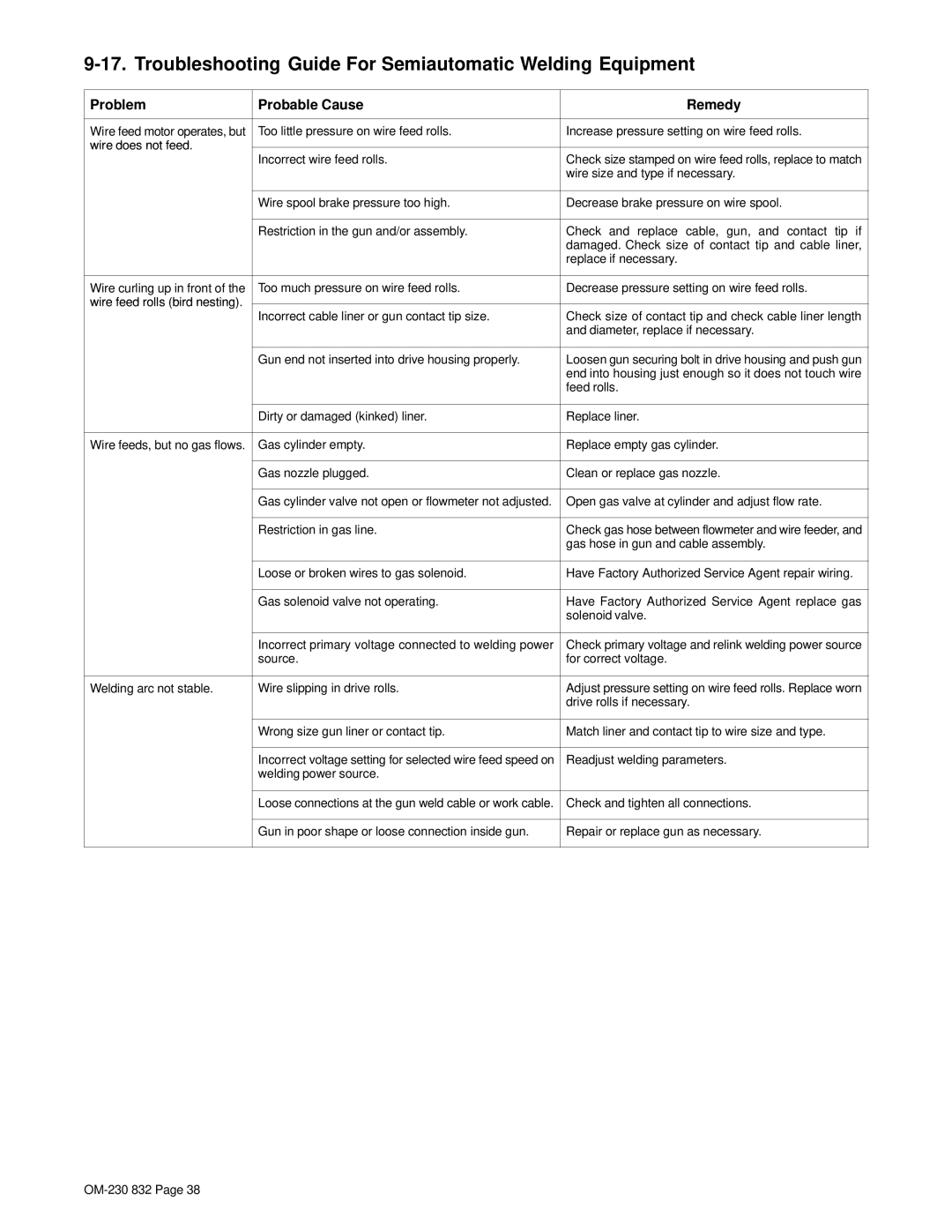

9-17. Troubleshooting Guide For Semiautomatic Welding Equipment

Problem | Probable Cause | Remedy | |

|

|

| |

Wire feed motor operates, but | Too little pressure on wire feed rolls. | Increase pressure setting on wire feed rolls. | |

wire does not feed. |

|

| |

Incorrect wire feed rolls. | Check size stamped on wire feed rolls, replace to match | ||

| |||

|

| wire size and type if necessary. | |

|

|

| |

| Wire spool brake pressure too high. | Decrease brake pressure on wire spool. | |

|

|

| |

| Restriction in the gun and/or assembly. | Check and replace cable, gun, and contact tip if | |

|

| damaged. Check size of contact tip and cable liner, | |

|

| replace if necessary. | |

|

|

| |

Wire curling up in front of the | Too much pressure on wire feed rolls. | Decrease pressure setting on wire feed rolls. | |

wire feed rolls (bird nesting). |

|

| |

Incorrect cable liner or gun contact tip size. | Check size of contact tip and check cable liner length | ||

| |||

|

| and diameter, replace if necessary. | |

|

|

| |

| Gun end not inserted into drive housing properly. | Loosen gun securing bolt in drive housing and push gun | |

|

| end into housing just enough so it does not touch wire | |

|

| feed rolls. | |

|

|

| |

| Dirty or damaged (kinked) liner. | Replace liner. | |

|

|

| |

Wire feeds, but no gas flows. | Gas cylinder empty. | Replace empty gas cylinder. | |

|

|

| |

| Gas nozzle plugged. | Clean or replace gas nozzle. | |

|

|

| |

| Gas cylinder valve not open or flowmeter not adjusted. | Open gas valve at cylinder and adjust flow rate. | |

|

|

| |

| Restriction in gas line. | Check gas hose between flowmeter and wire feeder, and | |

|

| gas hose in gun and cable assembly. | |

|

|

| |

| Loose or broken wires to gas solenoid. | Have Factory Authorized Service Agent repair wiring. | |

|

|

| |

| Gas solenoid valve not operating. | Have Factory Authorized Service Agent replace gas | |

|

| solenoid valve. | |

|

|

| |

| Incorrect primary voltage connected to welding power | Check primary voltage and relink welding power source | |

| source. | for correct voltage. | |

|

|

| |

Welding arc not stable. | Wire slipping in drive rolls. | Adjust pressure setting on wire feed rolls. Replace worn | |

|

| drive rolls if necessary. | |

|

|

| |

| Wrong size gun liner or contact tip. | Match liner and contact tip to wire size and type. | |

|

|

| |

| Incorrect voltage setting for selected wire feed speed on | Readjust welding parameters. | |

| welding power source. |

| |

|

|

| |

| Loose connections at the gun weld cable or work cable. | Check and tighten all connections. | |

|

|

| |

| Gun in poor shape or loose connection inside gun. | Repair or replace gun as necessary. | |

|

|

|