Troubleshooting − Excessive Spatter | ||

|

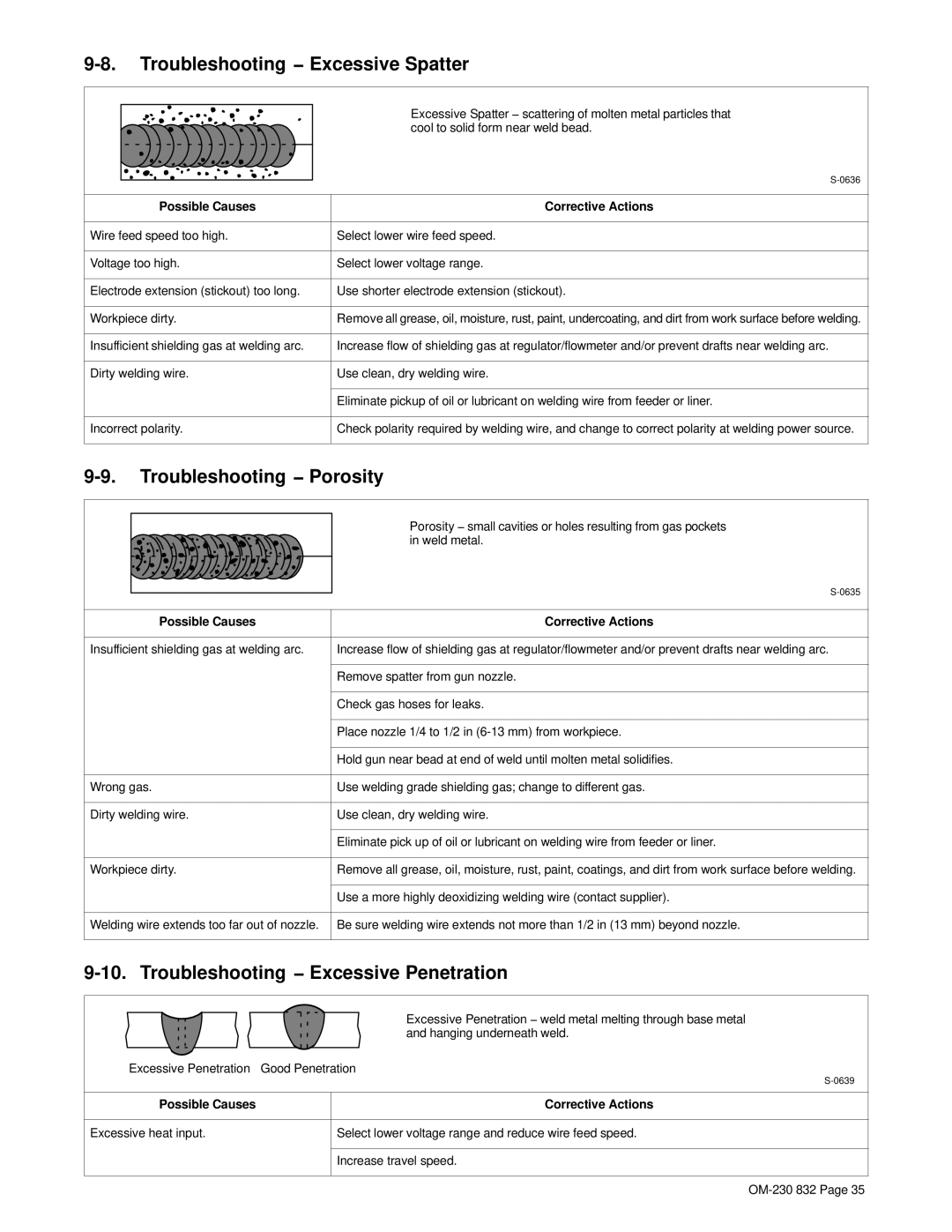

| Excessive Spatter − scattering of molten metal particles that |

|

| cool to solid form near weld bead. |

|

| |

| Possible Causes | Corrective Actions |

Wire feed speed too high. | Select lower wire feed speed. | |

Voltage too high. | Select lower voltage range. | |

Electrode extension (stickout) too long. | Use shorter electrode extension (stickout). | |

Workpiece dirty. | Remove all grease, oil, moisture, rust, paint, undercoating, and dirt from work surface before welding. | |

Insufficient shielding gas at welding arc. | Increase flow of shielding gas at regulator/flowmeter and/or prevent drafts near welding arc. | |

Dirty welding wire. | Use clean, dry welding wire. | |

|

| Eliminate pickup of oil or lubricant on welding wire from feeder or liner. |

Incorrect polarity. | Check polarity required by welding wire, and change to correct polarity at welding power source. | |

Troubleshooting − Porosity | ||

|

| Porosity − small cavities or holes resulting from gas pockets |

|

| in weld metal. |

|

| |

| Possible Causes | Corrective Actions |

Insufficient shielding gas at welding arc. | Increase flow of shielding gas at regulator/flowmeter and/or prevent drafts near welding arc. | |

|

| Remove spatter from gun nozzle. |

|

| Check gas hoses for leaks. |

|

| Place nozzle 1/4 to 1/2 in |

|

| Hold gun near bead at end of weld until molten metal solidifies. |

Wrong gas. | Use welding grade shielding gas; change to different gas. | |

Dirty welding wire. | Use clean, dry welding wire. | |

|

| Eliminate pick up of oil or lubricant on welding wire from feeder or liner. |

Workpiece dirty. | Remove all grease, oil, moisture, rust, paint, coatings, and dirt from work surface before welding. | |

|

| Use a more highly deoxidizing welding wire (contact supplier). |

Welding wire extends too far out of nozzle. | Be sure welding wire extends not more than 1/2 in (13 mm) beyond nozzle. | |

9-10. Troubleshooting − Excessive Penetration

Excessive Penetration − weld metal melting through base metal and hanging underneath weld.

Excessive Penetration Good Penetration

Possible Causes | Corrective Actions |

|

|

Excessive heat input. | Select lower voltage range and reduce wire feed speed. |

|

|

| Increase travel speed. |

|

|