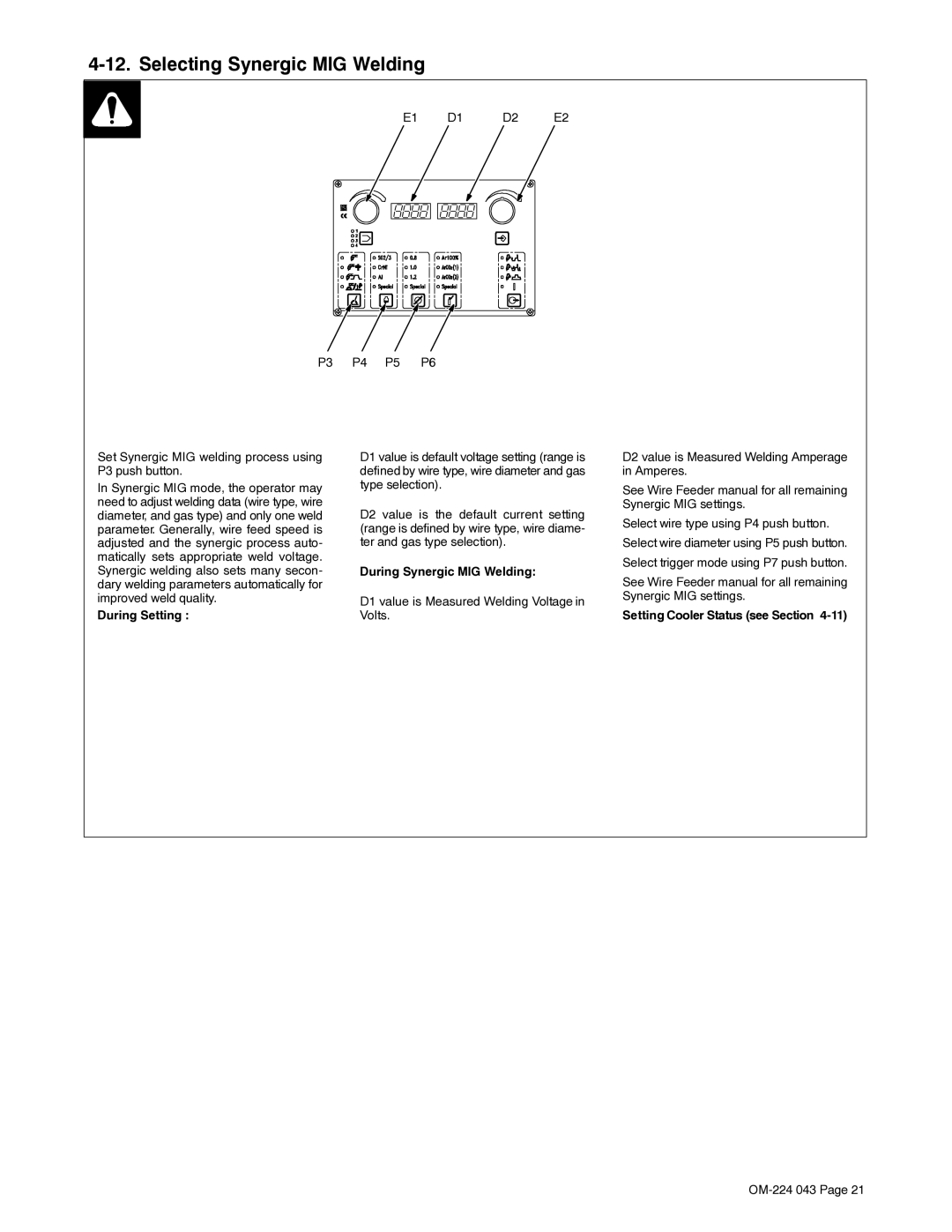

4-12. Selecting Synergic MIG Welding

| E1 | D1 | D2 | E2 |

|

|

|

|

|

P3 P4 P5 P6

Set Synergic MIG welding process using P3 push button.

In Synergic MIG mode, the operator may need to adjust welding data (wire type, wire diameter, and gas type) and only one weld parameter. Generally, wire feed speed is adjusted and the synergic process auto- matically sets appropriate weld voltage. Synergic welding also sets many secon- dary welding parameters automatically for improved weld quality.

During Setting :

D1 value is default voltage setting (range is defined by wire type, wire diameter and gas type selection).

D2 value is the default current setting (range is defined by wire type, wire diame- ter and gas type selection).

During Synergic MIG Welding:

D1 value is Measured Welding Voltage in Volts.

D2 value is Measured Welding Amperage in Amperes.

See Wire Feeder manual for all remaining Synergic MIG settings.

Select wire type using P4 push button. Select wire diameter using P5 push button. Select trigger mode using P7 push button.

See Wire Feeder manual for all remaining Synergic MIG settings.