3-8. Circuit Breakers

1

2

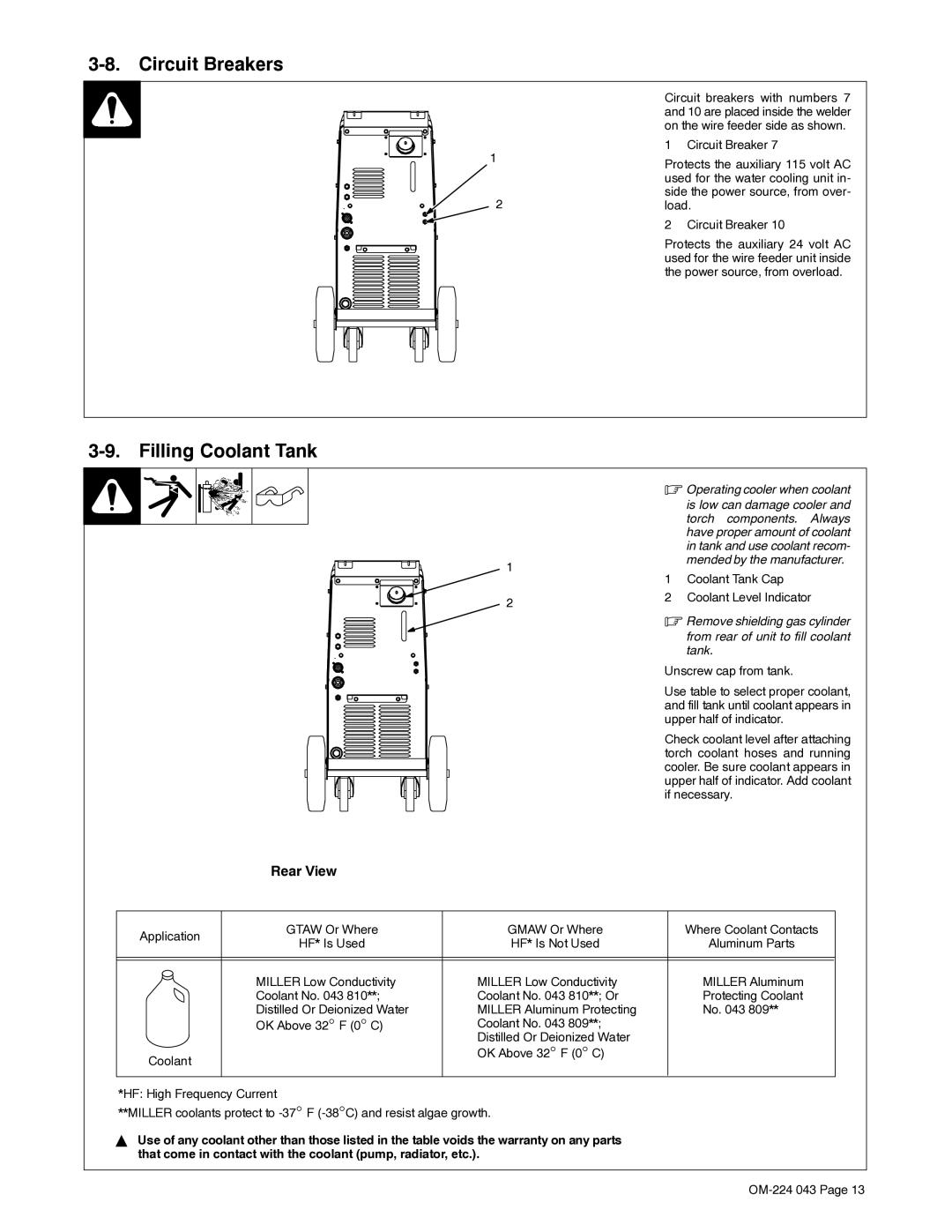

Circuit breakers with numbers 7 and 10 are placed inside the welder on the wire feeder side as shown.

1 Circuit Breaker 7

Protects the auxiliary 115 volt AC used for the water cooling unit in- side the power source, from over- load.

2 Circuit Breaker 10

Protects the auxiliary 24 volt AC used for the wire feeder unit inside the power source, from overload.

3-9. Filling Coolant Tank

1

2

.Operating cooler when coolant

is low can damage cooler and torch components. Always have proper amount of coolant in tank and use coolant recom- mended by the manufacturer.

1Coolant Tank Cap

2Coolant Level Indicator

.Remove shielding gas cylinder

from rear of unit to fill coolant tank.

Unscrew cap from tank.

Use table to select proper coolant, and fill tank until coolant appears in upper half of indicator.

Check coolant level after attaching torch coolant hoses and running cooler. Be sure coolant appears in upper half of indicator. Add coolant if necessary.

Rear View

Application | GTAW Or Where | GMAW Or Where | Where Coolant Contacts | ||

HF* Is Used | HF* Is Not Used | Aluminum Parts | |||

| |||||

|

|

|

| ||

| MILLER Low Conductivity | MILLER Low Conductivity | MILLER Aluminum | ||

| Coolant No. 043 810**; | Coolant No. 043 810**; Or | Protecting Coolant | ||

| Distilled Or Deionized Water | MILLER Aluminum Protecting | No. 043 809** | ||

| ° | ° | Coolant No. 043 809**; |

| |

| OK Above 32 | F (0 C) | Distilled Or Deionized Water |

| |

|

|

|

| ||

Coolant |

|

| OK Above 32° F (0° C) |

| |

|

|

|

| ||

|

|

|

|

| |

*HF: High Frequency Current

**MILLER coolants protect to

YUse of any coolant other than those listed in the table voids the warranty on any parts that come in contact with the coolant (pump, radiator, etc.).