7. Aligning the seams of the terminal and air terminal connector, |

place the terminal over the air terminal connector making sure |

the liner goes into the hole in the terminal. Secure with the three |

screws provided. Figure 22c |

8. Apply a heavy bead of |

flashing. NOTE: Maintain a minimum 2” space between the air |

inlet base and the storm collar. Install the storm collar around the |

air terminal connector and slide down to the caulking. Tighten to |

ensure that a |

connector and collar is achieved. |

9. Continue adding rigid venting sections, sealing and securing |

as above. Attach a 4" collapsed telescopic sleeve to the last |

15

4.When flexing any gas line, support the gas valve so that the lines are not bent or kinked.

5.Check for gas leaks by brushing on a soap and water solution.

Do not use open flame.

Purge all gas lines with the glass door of the stove removed. Assure that a continuous gas flow is at the burner before

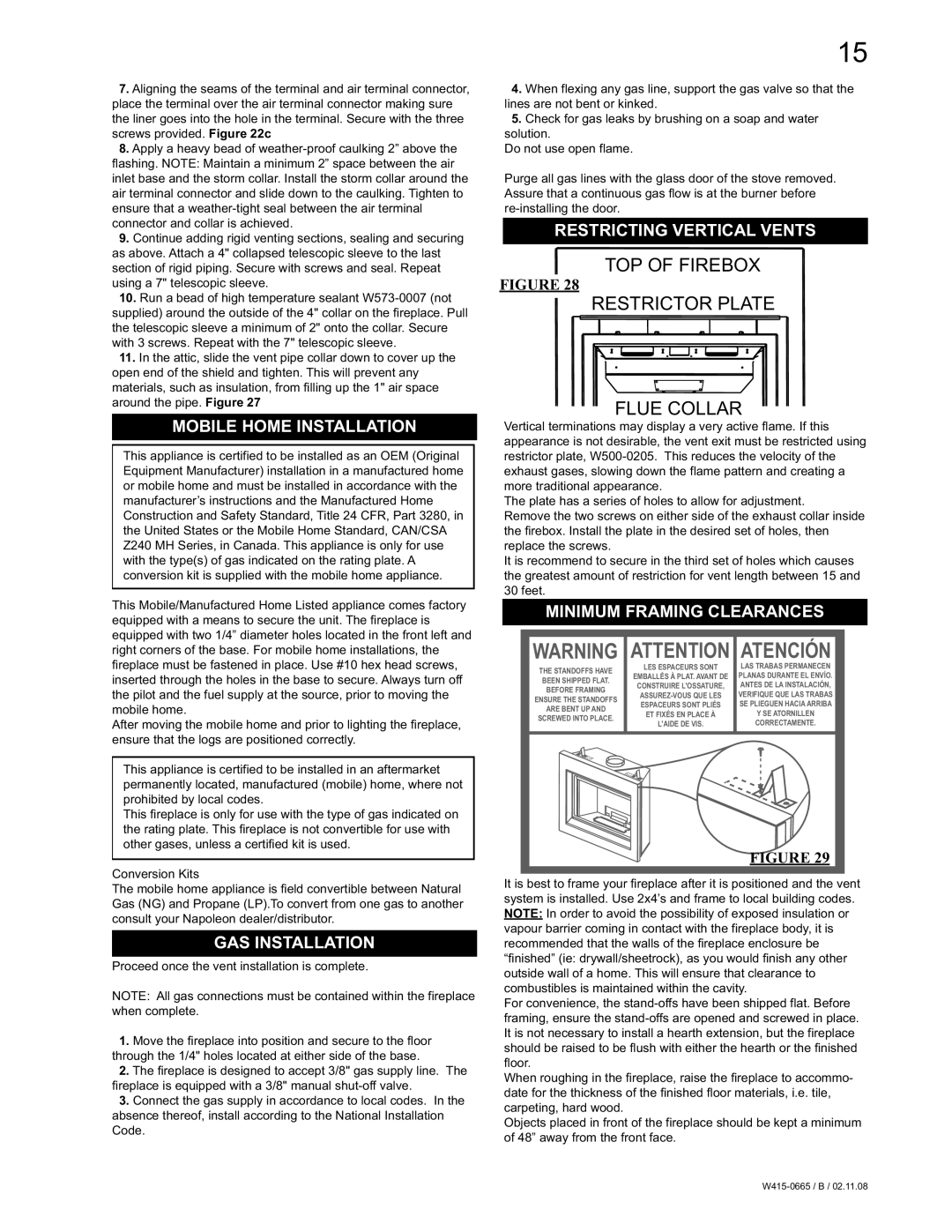

RESTRICTING VERTICAL VENTS

section of rigid piping. Secure with screws and seal. Repeat |

using a 7" telescopic sleeve. |

10. Run a bead of high temperature sealant |

supplied) around the outside of the 4" collar on the fireplace. Pull |

the telescopic sleeve a minimum of 2" onto the collar. Secure |

with 3 screws. Repeat with the 7" telescopic sleeve. |

11. In the attic, slide the vent pipe collar down to cover up the |

open end of the shield and tighten. This will prevent any |

materials, such as insulation, from filling up the 1" air space |

around the pipe. Figure 27 |

FIGURE 28

TOP OF FIREBOX RESTRICTOR PLATE

FLUE COLLAR

MOBILE HOME INSTALLATION

This appliance is certified to be installed as an OEM (Original Equipment Manufacturer) installation in a manufactured home or mobile home and must be installed in accordance with the manufacturer’s instructions and the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280, in the United States or the Mobile Home Standard, CAN/CSA Z240 MH Series, in Canada. This appliance is only for use with the type(s) of gas indicated on the rating plate. A conversion kit is supplied with the mobile home appliance.

This Mobile/Manufactured Home Listed appliance comes factory equipped with a means to secure the unit. The fireplace is equipped with two 1/4” diameter holes located in the front left and right corners of the base. For mobile home installations, the fireplace must be fastened in place. Use #10 hex head screws, inserted through the holes in the base to secure. Always turn off the pilot and the fuel supply at the source, prior to moving the mobile home.

After moving the mobile home and prior to lighting the fireplace, ensure that the logs are positioned correctly.

This appliance is certified to be installed in an aftermarket permanently located, manufactured (mobile) home, where not prohibited by local codes.

This fireplace is only for use with the type of gas indicated on the rating plate. This fireplace is not convertible for use with other gases, unless a certified kit is used.

Conversion Kits

The mobile home appliance is field convertible between Natural Gas (NG) and Propane (LP).To convert from one gas to another consult your Napoleon dealer/distributor.

GAS INSTALLATION

Proceed once the vent installation is complete.

NOTE: All gas connections must be contained within the fireplace when complete.

1.Move the fireplace into position and secure to the floor through the 1/4" holes located at either side of the base.

2.The fireplace is designed to accept 3/8" gas supply line. The fireplace is equipped with a 3/8" manual

3.Connect the gas supply in accordance to local codes. In the absence thereof, install according to the National Installation Code.

Vertical terminations may display a very active flame. If this appearance is not desirable, the vent exit must be restricted using restrictor plate,

The plate has a series of holes to allow for adjustment.

Remove the two screws on either side of the exhaust collar inside the firebox. Install the plate in the desired set of holes, then replace the screws.

It is recommend to secure in the third set of holes which causes the greatest amount of restriction for vent length between 15 and 30 feet.

MINIMUM FRAMING CLEARANCES

WARNING | ATTENTION | ATENCIÓN | |

THE STANDOFFS HAVE | LES ESPACEURS SONT | LAS TRABAS PERMANECEN | |

EMBALLÉS À PLAT. AVANT DE | PLANAS DURANTE EL ENVÍO. | ||

BEEN SHIPPED FLAT. | |||

CONSTRUIRE L'OSSATURE, | ANTES DE LA INSTALACIÓN, | ||

BEFORE FRAMING | |||

VERIFIQUE QUE LAS TRABAS | |||

ENSURE THE STANDOFFS | |||

ESPACEURS SONT PLIÉS | SE PLIEGUEN HACIA ARRIBA | ||

ARE BENT UP AND | |||

ET FIXÉS EN PLACE À | Y SE ATORNILLEN | ||

SCREWED INTO PLACE. | |||

L'AIDE DE VIS. | CORRECTAMENTE. | ||

| |||

|

|

|

FIGURE 29

It is best to frame your fireplace after it is positioned and the vent system is installed. Use 2x4’s and frame to local building codes. NOTE: In order to avoid the possibility of exposed insulation or vapour barrier coming in contact with the fireplace body, it is recommended that the walls of the fireplace enclosure be “finished” (ie: drywall/sheetrock), as you would finish any other outside wall of a home. This will ensure that clearance to combustibles is maintained within the cavity.

For convenience, the

When roughing in the fireplace, raise the fireplace to accommo- date for the thickness of the finished floor materials, i.e. tile, carpeting, hard wood.

Objects placed in front of the fireplace should be kept a minimum of 48” away from the front face.