Chapter 2

Installation and Wiring

The linearity and accuracy of the

2.1 Location of Fitting

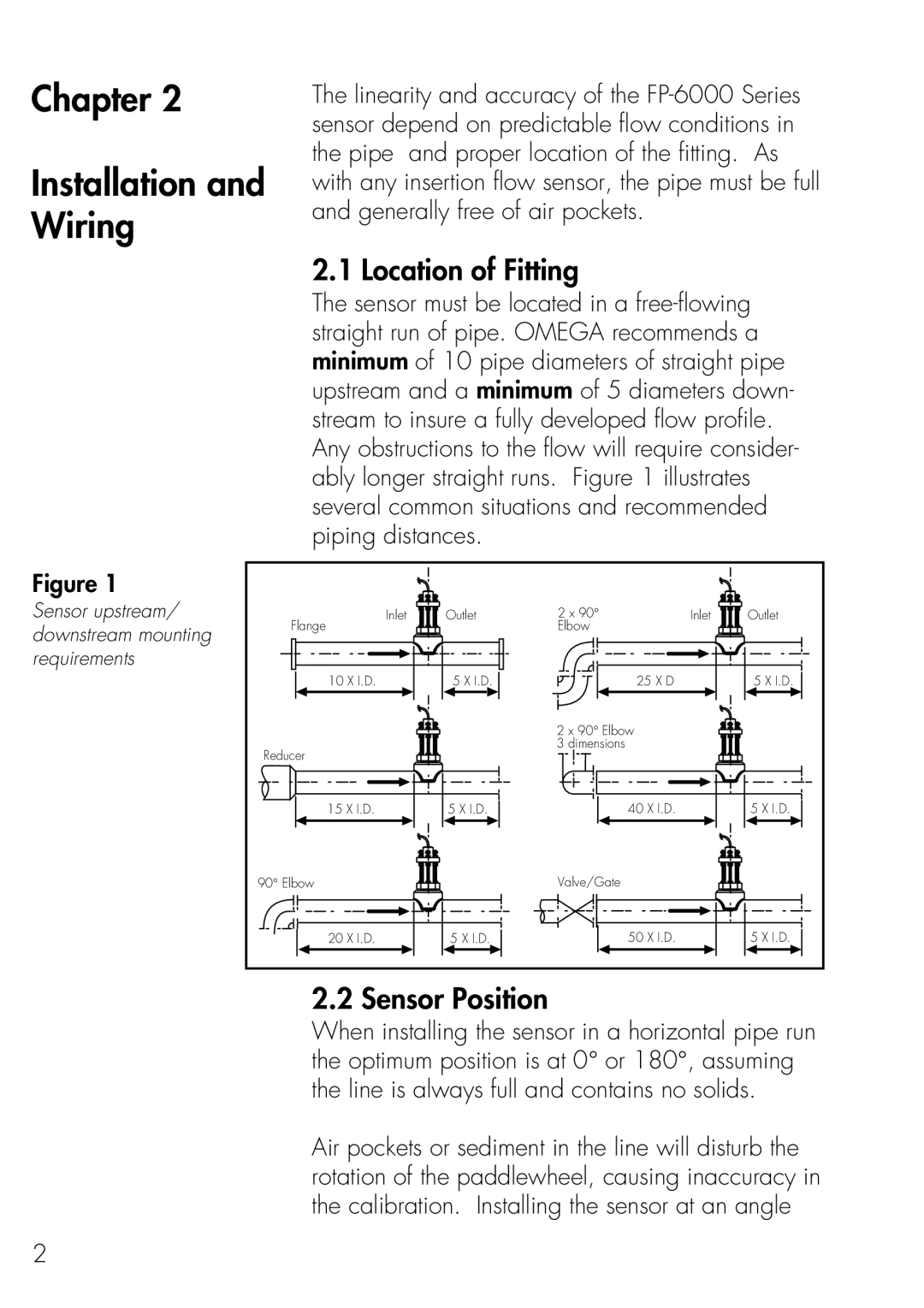

The sensor must be located in a

Figure 1

Sensor upstream/ downstream mounting requirements

Inlet | Outlet | 2 x 90° | Inlet | Outlet |

Flange |

| Elbow |

|

|

10 X I.D. | 5 X I.D. | 25 X D |

| 5 X I.D. |

|

| 2 x 90° Elbow |

|

|

Reducer |

| 3 dimensions |

|

|

|

|

|

| |

15 X I.D. | 5 X I.D. | 40 X I.D. |

| 5 X I.D. |

90° Elbow |

| Valve/Gate |

|

|

20 X I.D. | 5 X I.D. | 50 X I.D. |

| 5 X I.D. |

2.2 Sensor Position

When installing the sensor in a horizontal pipe run the optimum position is at 0° or 180°, assuming the line is always full and contains no solids.

Air pockets or sediment in the line will disturb the rotation of the paddlewheel, causing inaccuracy in the calibration. Installing the sensor at an angle

2