NOTE: The knives must be extended beyond the cutterhead by 1/32”. (see “Replacing Knives – Straight Cutterhead Only” on page 23 for this procedure).

4.

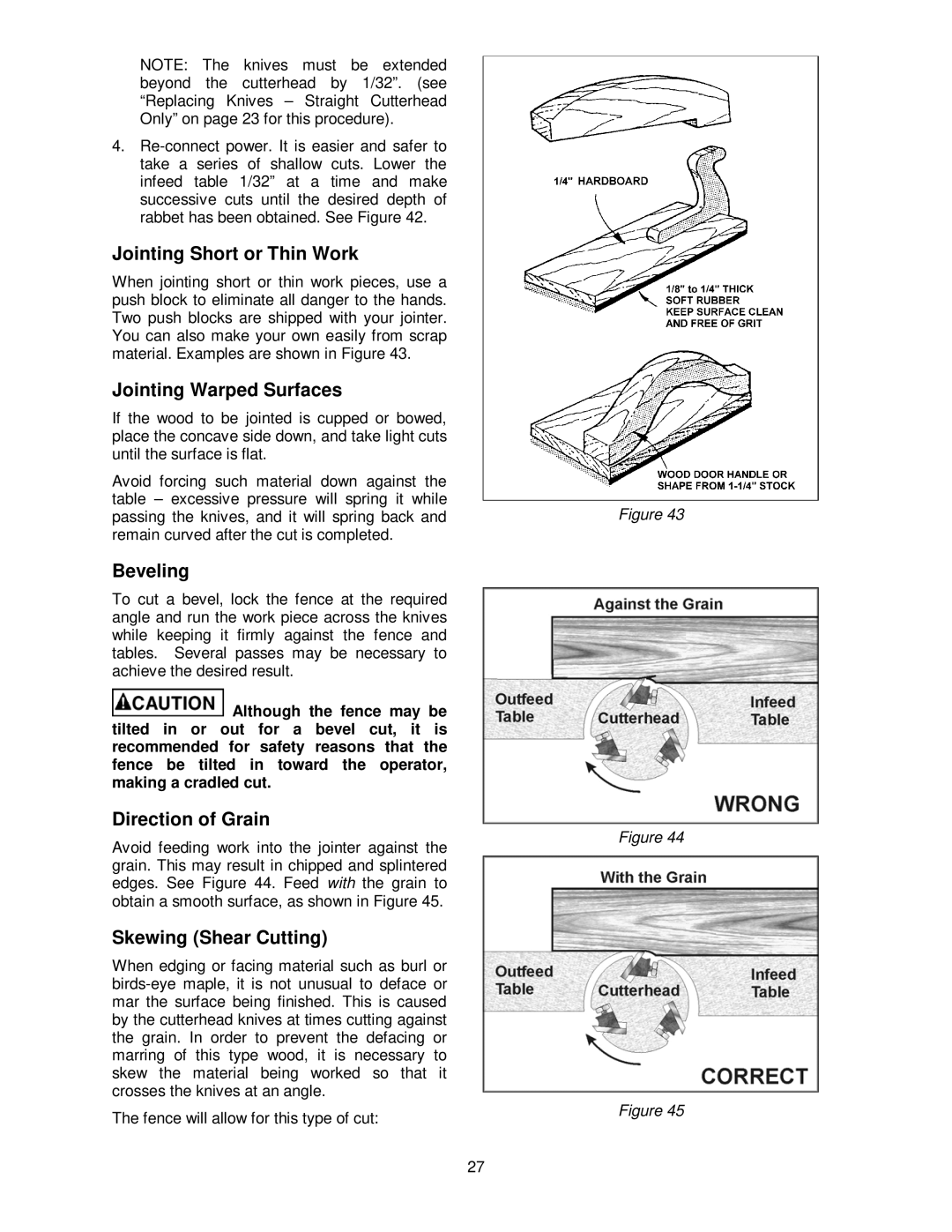

Jointing Short or Thin Work

When jointing short or thin work pieces, use a push block to eliminate all danger to the hands. Two push blocks are shipped with your jointer. You can also make your own easily from scrap material. Examples are shown in Figure 43.

Jointing Warped Surfaces

If the wood to be jointed is cupped or bowed, place the concave side down, and take light cuts until the surface is flat.

Avoid forcing such material down against the table – excessive pressure will spring it while passing the knives, and it will spring back and remain curved after the cut is completed.

Beveling

To cut a bevel, lock the fence at the required angle and run the work piece across the knives while keeping it firmly against the fence and tables. Several passes may be necessary to achieve the desired result.

![]() Although the fence may be tilted in or out for a bevel cut, it is recommended for safety reasons that the fence be tilted in toward the operator, making a cradled cut.

Although the fence may be tilted in or out for a bevel cut, it is recommended for safety reasons that the fence be tilted in toward the operator, making a cradled cut.

Direction of Grain

Avoid feeding work into the jointer against the grain. This may result in chipped and splintered edges. See Figure 44. Feed with the grain to obtain a smooth surface, as shown in Figure 45.

Skewing (Shear Cutting)

When edging or facing material such as burl or

The fence will allow for this type of cut:

Figure 43

Figure 44

Figure 45

27