Sharpening Standard Knives

Knives should be kept sharp. This will contribute to better stock finish, longer machine life, and safer operation.

A jointer knife hone provides a simple way to sharpen knives. Hones are available from many woodworking supply stores. Carefully read any instructions that accompany the hone.

![]() Use caution and proceed slowly when sharpening knives. Disconnect jointer from power source, and wear approved eye protection.

Use caution and proceed slowly when sharpening knives. Disconnect jointer from power source, and wear approved eye protection.

When finished sharpening knives, they should be

Knives can usually be whetted several times in the cutterhead before having to be removed and

TIP: If the jointer is used frequently, keeping a spare set of knives on hand is recommended. Extra knives (stock no. 6296046, set of 3) may be obtained from your distributor, or by calling customer service at

Cutterhead Repairs

The entire cutterhead assembly may be removed from the Jointer for bearing replacement or other maintenance procedures.

Use caution when working around sharp knives.

Use caution when working around sharp knives.

To remove the cutterhead, proceed as follows:

1.Disconnect jointer from power source.

2.Remove fence assembly from jointer.

3.Lower both infeed and outfeed table.

4.Remove belt guard, and remove drive belt from around cutterhead pulley.

5.Remove knives from cutterhead.

6.Remove rabbeting ledge by loosening and removing the two hex cap screws and washers which secure it to the infeed table.

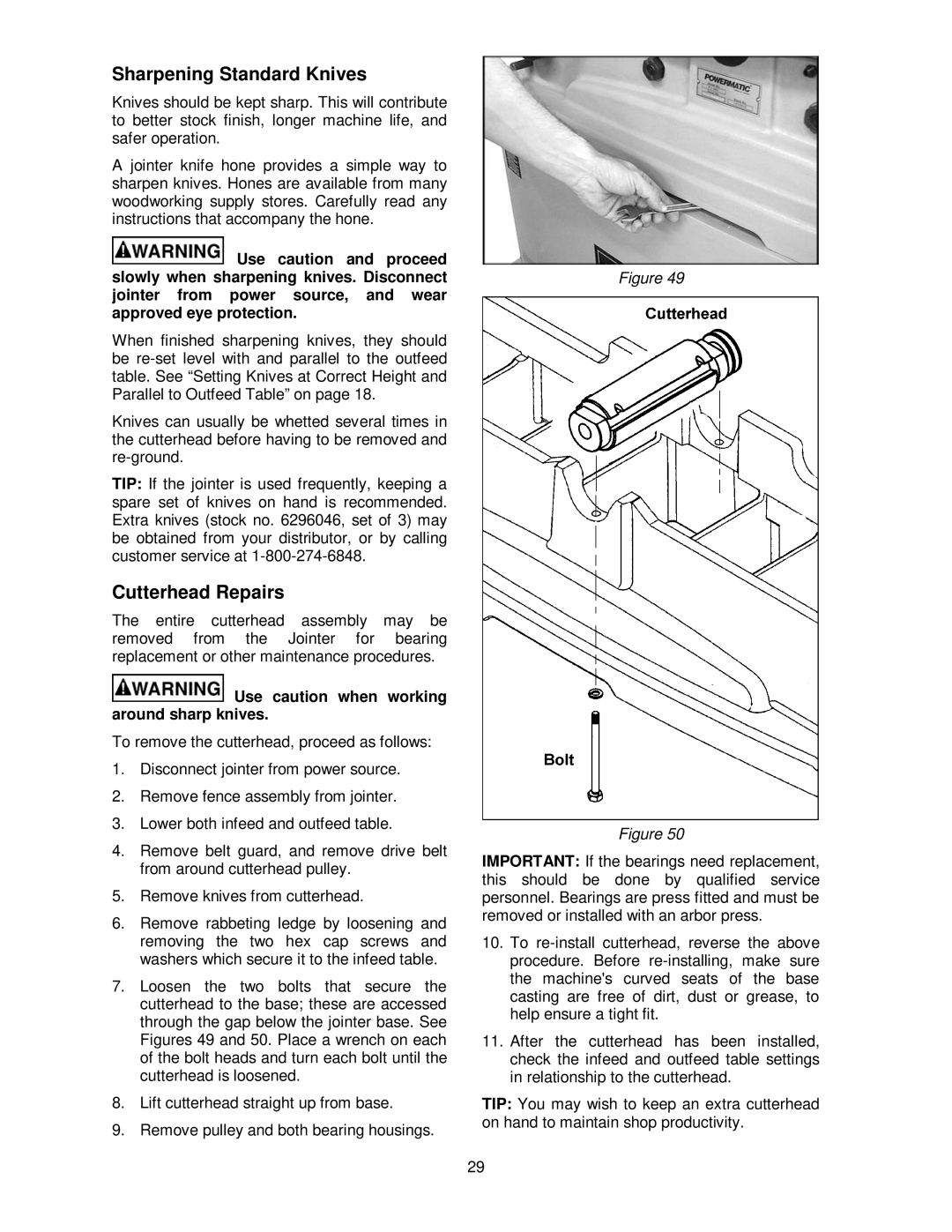

7.Loosen the two bolts that secure the cutterhead to the base; these are accessed through the gap below the jointer base. See Figures 49 and 50. Place a wrench on each of the bolt heads and turn each bolt until the cutterhead is loosened.

8.Lift cutterhead straight up from base.

9.Remove pulley and both bearing housings.

Figure 49

Figure 50

IMPORTANT: If the bearings need replacement, this should be done by qualified service personnel. Bearings are press fitted and must be removed or installed with an arbor press.

10.To

11.After the cutterhead has been installed, check the infeed and outfeed table settings in relationship to the cutterhead.

TIP: You may wish to keep an extra cutterhead on hand to maintain shop productivity.

29