Powermatic

Part No. M-1610079

Warranty and Service

Warranty Period

Table of Contents

Page

Page

Page

Specifications

Introduction Description

Contents of the Shipping Container

Unpacking

Installation and Assembly

Tools required for assembly

Installing Switch Arm

Installing Cutterhead Guard

Grounding Instructions

Dust Collection

Extension cords

Volt, Single Phase Operation

Three Phase Operation

Drive Belt Tension

Adjustments

Drive Belt Replacement

Fence Movement

To slide fence forward or backward

To tilt fence forward

To tilt fence backward

Fence Stops

Setting the 90 Stop

Setting the 45 Forward Stop

Table and Knife Adjustments

Setting the 45 Backward Stop

Fence Removal

Locking Handles

Setting Tables Coplanar

Back of outfeed table shown

Page

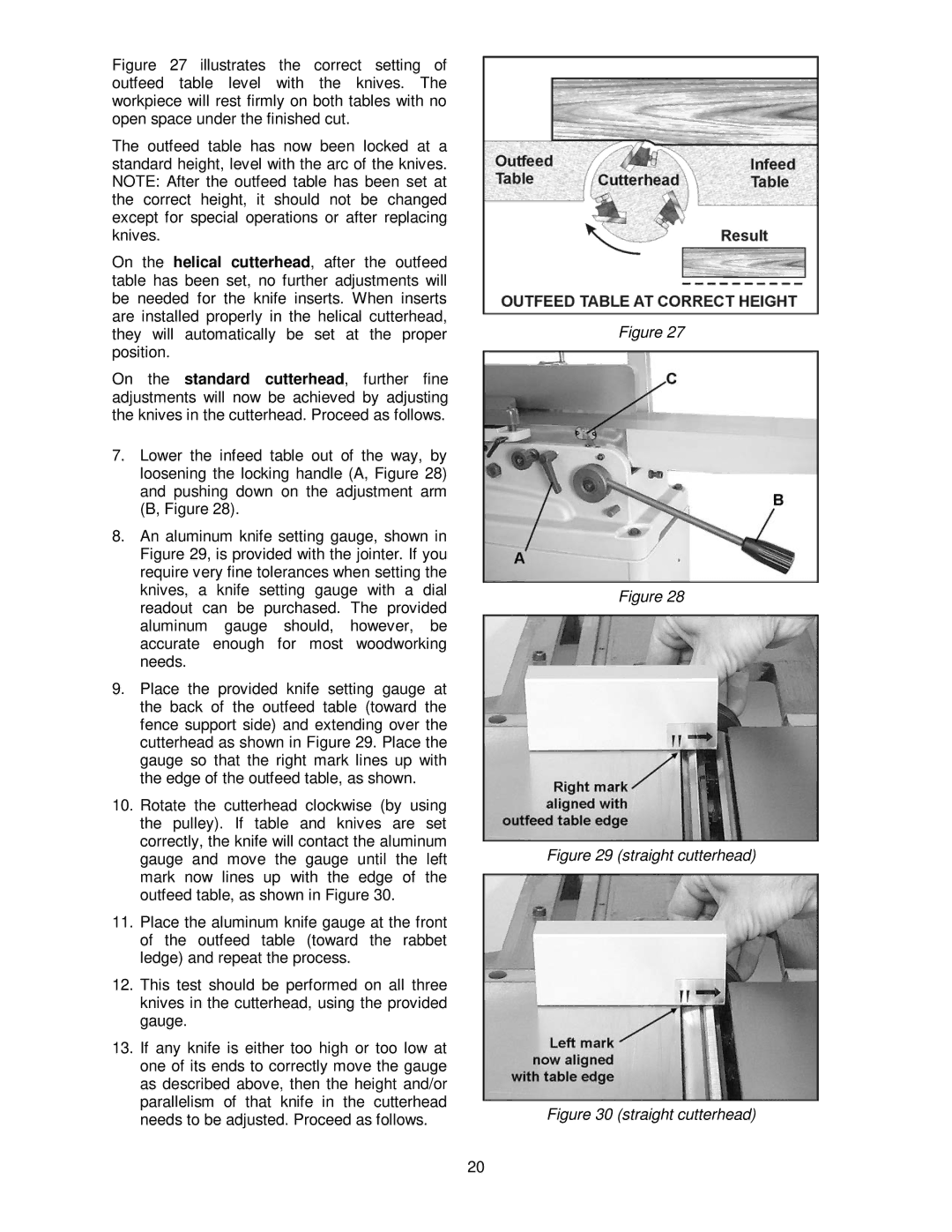

Straight cutterhead

Straight cutterhead

Setting Infeed Table Depth of Cut

Outfeed Table Stop Screws

Infeed Table Depth Stop

Infeed Table Stop Screws

Replacing Knives Straight Cutterhead Only

Replacing or Rotating Knife Inserts Helical Cutterhead Only

Eliminating Play in Tables

Safety Key

Operating Controls

Operation

Start/Stop

Hand Placement

Always use a hold down or push block when surfacing stock

Surfacing

Edge Jointing

Jointing Short or Thin Work

Jointing Warped Surfaces

Beveling

Direction of Grain

Maintenance

Cutterhead Repairs

Use caution when working around sharp knives

Sharpening Standard Knives

Probable Cause Remedy

Troubleshooting Operating Problems

Trouble

Troubleshooting Mechanical and Electrical Problems

Trouble Probable Cause Remedy

Optional Accessories

Replacement Parts

Parts List Stand Assembly

Index No. Part No Description Size Qty

PJ882-543

Stand Assembly

Parts List Cutterhead Assembly Model PJ-882 only

PJ882-CHA

Parts List Cutterhead Assembly Model PJ-882HH only

PJ882HH-CA

Parts List Fence Assembly

Fence Assembly

Parts List Outfeed Table and Base Assembly

Outfeed Table and Base Assembly

Parts List Infeed Table Assembly

PJ882-246

Electrical Connections 1 Phase, 230 Volt

Electrical Connections 3 Phase, 230 Volt

Electrical Connections 3 Phase, 460 Volt

Page

New Sanford Road LaVergne, Tennessee

Canteadora de Paralelogramo de 8 Pulgadas

Parte Nro. M-1610079

Garantía y Servicio Técnico

Período de la Garantía

Índice

Page

Page

Page

Especificaciones

Introducción

Descripción

Desempaque

Contenido del Cont. de Transporte

Instalación y Montaje

Herramientas requeridas para el montaje

Instalación del Interruptor de Brazo

Instalación de la Guarda de la Cabeza de Corte

Instrucciones de Puesta a Tierra

Colector de Polvo

Operación Trifásica

Cables de Extensión

Operación Monofásica a 230 Volt

Ajustes

Tensionamiento de la Correa de Impulsión

Sustitución de la Correa de Impulsión

Movimiento de la Guía

Para deslizar la guía hacia adelante y hacia atrás

Para inclinar la guía hacia adelante

Topes de la Guía

Para inclinar la guía hacia atrás

Posicionamiento del tope de 90 grados

Posicionamiento del tope de avance de 45 grados

Desmontaje de la Guía

Manijas de Bloqueo

Ajustes de la Mesa y la Cuchilla

Posicionamiento del tope de retroceso de 45 grados

Ajuste Coplanar de las Mesas

Figura Se observa la parte posterior de la mesa salida

Figura

Figura 29 cabeza de corte recta

Figura 31 cabeza de corte recta

Tornillos de Tope de la Mesa de Salida

Ajustando la Mesa de Entrada Profundidad de Corte

Tope de Profundidad de la Mesa de Entrada

Tornillos del Tope de la Mesa de Entrada

Figura 36 cabeza de corte recto

Eliminación del Juego en las Mesas

Figura 37A Solamente para cabeza de corte helicoidal

Controles de Operación

Operación

Marcha/Parada

Llave de Seguridad

Operación Manual

Cepillado

Ensamble Modular

Acanalado

Canteado de Piezas Cortas o Finas

Ensamblado de Superficies Alabeadas

Biselado

Dirección del Grano

Mantenimiento

Libere la manija de bloque o de la guía A, Fig

Sea cauteloso al trabajar cerca de cuchillas afiladas

Afilado de las Cuchillas Estándares

Reparaciones de la Cabeza de Corte

Causa Probable Solución

Diagnóstico de Problemas Problemas de Operación

Problema

Diagnóstico de Problemas Problemas Eléctricos y Mecánicos

Lista de Partes

Problema Causa Probable Solución

Accesorios Opcionales

Lista de Partes Conjunto de Base

Nro de Lista. Parte Nro Descripción Tamaño Cantidad

Dispositivo de Alivio de Presión 60B-447A PJ882-546

Conjunto de Base

Conjunto de la Cabeza de Corte Ítems 1 al 5, y 10 al

TS-0267021 Tornillo de Cabeza Hueca 20x1/4 PJ882-407

Lista de Partes Conjunto Guía

Nro. de Lista. Parte Nro Descripción Tamaño Cantidad

Conjunto Guía

Lista de Partes Conjunto de Mesa de Salida y Base

Conjunto de Mesa de Salida y Base

Lista de Partes Conjunto de Mesa de Entrada

PJ882-246

Conexiones Eléctricas Sistema Monofásico, 230 Voltios

Conexiones Eléctricas Sistema Trifásico, 230 Voltios

Conexiones Eléctricas Sistema Trifásico, 460 Voltios

Page

New Sanford Rd LaVergne, TN Teléfono

Dresseuse 8 pouces en parallélogramme

Pièce N. M-1610079

Garantie et entretien

Période de garantie

Table des matières

Liste des pièces Dispositif de la table dalimentation

Page

Page

Spécifications

Déballage

Le contenu du conteneur d’expédition

Installation et montage

Outils nécessaires à l’assemblage

Installation du bras du commutateur

Installation de la protection de la tête de la découpeuse

Instructions relatives à la mise à la masse

Collecte de la poussière

Fonctionnement sous phase unique de 230 volts

Fonctionnement sous trois phases

Recommandations

Rallonges

Réglages

Tension de la courroie de transmission

Remplacement de la courroie de transmission

Déplacement du guide

Pour faire coulisser le guide vers lavant ou larrière

Pour incliner le guide vers lavant

Arrêts du guide

Pour incliner le guide vers larrière

Réglage de larrêt de

Réglage de larrêt avant de

Retrait du guide

Manches de verrouillage

Réglages de la table et du couteau

Réglage de larrêt arrière de

Mise en coplanaire des tables

Arrière illustré de la table de sortie

Page

Tête de la découpeuse droite

Tête de la découpeuse droite

Vis darrêt de la table de sortie

Réglage de la table dalimentation profondeur de coupe

Arrêt de la profondeur de la table dalimentation

Vis darrêt de la table dalimentation

Tête de la découpeuse droite

Suppression du jeu dans les tables

Tête de la découpeuse hélicoïdale uniquement

Clé de sécurité

Fonctionnement

Démarrer/Arrêter

Installation de la main

Revêtement de surface

Assemblage de lextrémité

Refeuillement

Assemblage des travaux courts ou minces

Assemblage des surfaces déformées

Biseautage

Sens du grain

Inclinaison du guide

Affûtage des couteaux standard

Dépannage de la tête de la découpeuse

Cause possible Solution

Anomalies

Diagnostic des anomalies Problèmes mécaniques et électriques

Accessoires en option

Pièces de rechange

Liste des pièces Dispositif du support

’indice N de la pièce Description Taille Qté

’indic De la pièce Description Taille Qté

Dispositif du support

TS-0720091 Rondelle de verrouillage 6296154

Au total

Liste des pièces Dispositif du guide

Dispositif du guide

Liste des pièces Table dalimentation et dispositif du socle

Dispositif de table et support d’alimentation

Liste des pièces Dispositif de la table d’alimentation

PJ882-246

Connexions électriques monophase, 230 volts

Connexions électriques triphase, 230 volts

Connexions électriques triphase, 460 volts

Page

New Sanford Rd LaVergne, TN Téléphone