having it in the finished piece. Most checks radiate from the pith.

As you turn bowls from green wood, make sure you maintain a consistent wall thickness throughout the piece. Leaving a piece thick in some areas and thin in others will cause the wood to dry unevenly and promote checks and cracks.

11.4.5Distortion

Distortion is a problem associated with turning green wood. It will vary from one type of wood to the next. Typically, fruitwoods tend to distort more than others. It also varies with the time of year the tree was cut and how the logs are stored.

11.4.6Tools for bowl turning

The deep fluted bowl gouge is the most essential and versatile tool for most bowl and plate turning. The bowl gouge is heavier and easier to control than other types of gouges. It also allows removal of wood much faster and with less vibration than other gouges. Most average sized bowl work can be accomplished with a 3/8" or 1/2" bowl gouge. A 1/4" bowl gouge is best suited for smaller bowls and light finishing cuts. Larger 3/4" and 1" bowl gouges are only used for extremely large pieces.

Large domed scrapers can also be used to help clean up the interior surfaces of bowls. A light touch with the scraper slightly tilted will eliminate some of the ridges occasionally left by an inexperienced bowl gouge.

11.4.7Bowl Turning Techniques

To Shape Outside of Bowl:

1.Odd shaped burls, crotches and other irregular shaped blanks require special preparation before mounting in a chuck or onto a faceplate. Remove the bark, if there is any, from what appears to be the center of the top of the workpiece.

2.Drive spur center into the top of the workpiece with a mallet or dead blow hammer.

3.Slip the spur center into the headstock taper and bring the tailstock with a live or ball bearing center into position. Lock the tailstock to the bed and advance the tailstock spindle in order to seat the cup center into the workpiece. Tighten the ram locking handle.

4.Turn workpiece by hand to ensure proper clearance.

5.Start lathe at lowest speed and bring it up to the maximum safe speed for the size of work to be turned (see sect. 15.0). If the machine starts to vibrate, lower the speed until vibration stops.

6.Rough out the outside of the bowl with the 1/2" deep fluted bowl gouge, holding the handle of the tool firmly against your hip. For best

control, use your whole body to move the gouge through the workpiece.

7.As the bowl takes shape, work on the bottom (tailstock end) to accomodate attaching a face plate.

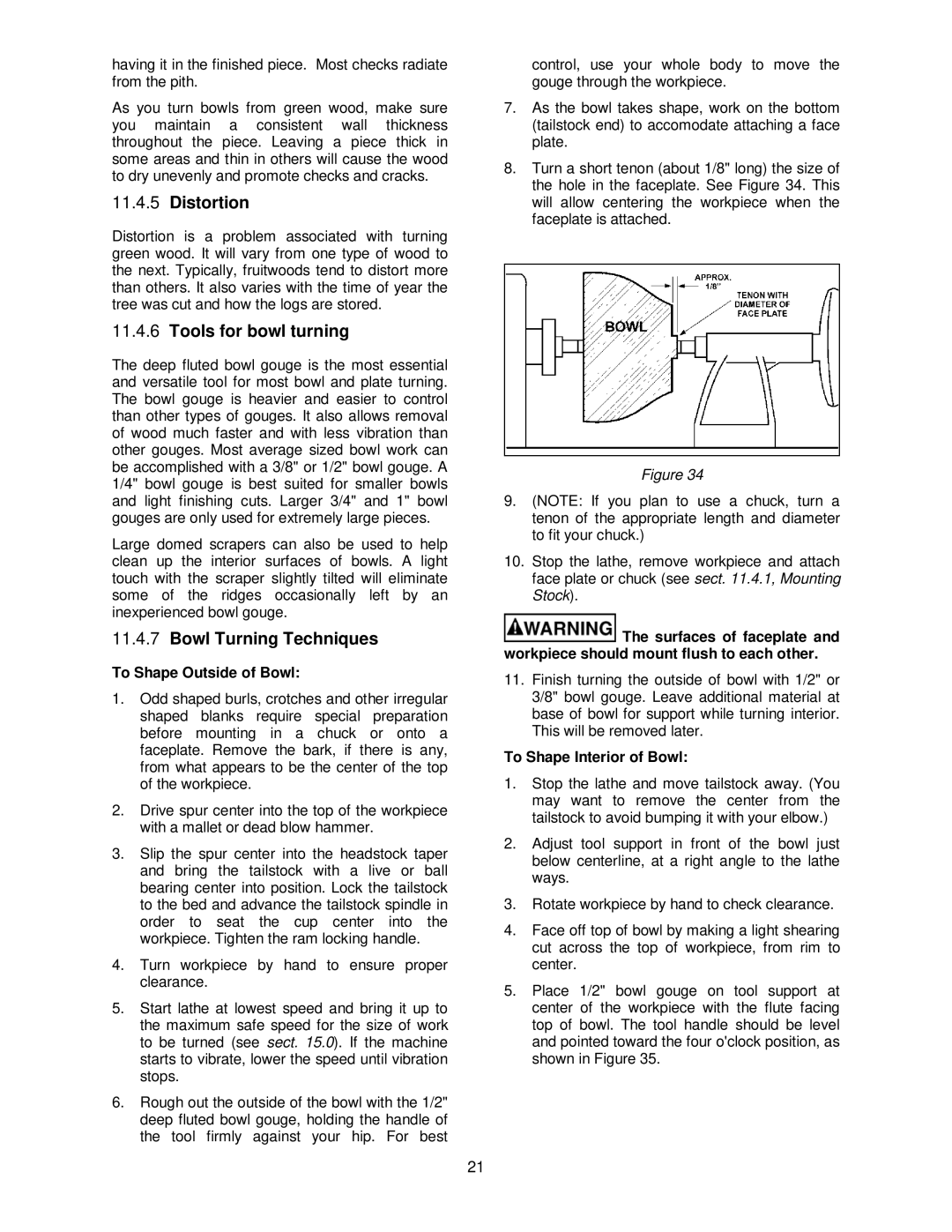

8.Turn a short tenon (about 1/8" long) the size of the hole in the faceplate. See Figure 34. This will allow centering the workpiece when the faceplate is attached.

Figure 34

9.(NOTE: If you plan to use a chuck, turn a tenon of the appropriate length and diameter to fit your chuck.)

10.Stop the lathe, remove workpiece and attach face plate or chuck (see sect. 11.4.1, Mounting Stock).

![]() The surfaces of faceplate and workpiece should mount flush to each other.

The surfaces of faceplate and workpiece should mount flush to each other.

11.Finish turning the outside of bowl with 1/2" or 3/8" bowl gouge. Leave additional material at base of bowl for support while turning interior. This will be removed later.

To Shape Interior of Bowl:

1.Stop the lathe and move tailstock away. (You may want to remove the center from the tailstock to avoid bumping it with your elbow.)

2.Adjust tool support in front of the bowl just below centerline, at a right angle to the lathe ways.

3.Rotate workpiece by hand to check clearance.

4.Face off top of bowl by making a light shearing cut across the top of workpiece, from rim to center.

5.Place 1/2" bowl gouge on tool support at center of the workpiece with the flute facing top of bowl. The tool handle should be level and pointed toward the four o'clock position, as shown in Figure 35.

21