5.Secure the machine to the floor with good qual- ity lag screws through the holes in the bottom of the cabinet.

6.Exposed metal parts such as the table top have been given a protective coating at the factory. This should be removed with a soft cloth and solvent (such as mineral spirits). Do not use an abrasive pad.

ELECTRICAL CONNECTIONS

WARNING: Electrical connections must

!be made by a qualified electrician. The machine must be properly grounded to help prevent electrical shock and possible death.

Before connecting power, make sure the electrical current of your power source matches the electrical system on the shaper.

To connect power, proceed as follows:

1.Remove two screws (A) and remove terminal strip cover (B). See Figure 8.

2.Remove clear plastic insulator (C) that covers the terminals. See Figure 9.

3.Insert power line through opening (D) of terminal strip box, shown in Figure 8.

4.Connect the three power lines to terminals L1, L2 and L3, as shown at (E) Figure 10. Also connect the green ground wire to terminal (F).

5.Reassemble the clear plastic insulator (C) and the terminal strip cover (B).

! | CAUTION: Make sure the incoming power |

matches the voltage on the motor plate. |

6. When wiring is completed, tape all power box joints to keep out dust.

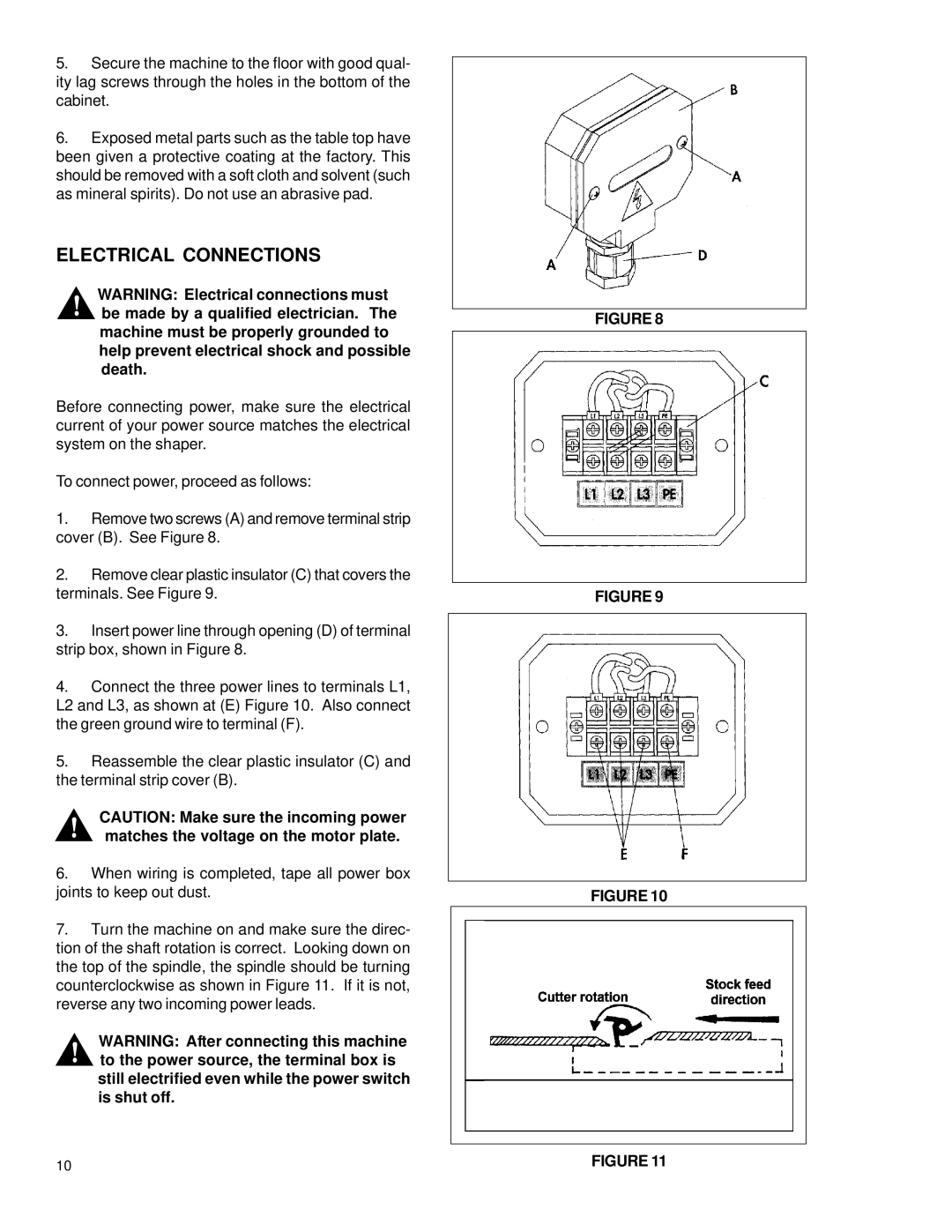

7. Turn the machine on and make sure the direc- tion of the shaft rotation is correct. Looking down on the top of the spindle, the spindle should be turning counterclockwise as shown in Figure 11. If it is not, reverse any two incoming power leads.

WARNING: After connecting this machine ! to the power source, the terminal box is

still electrified even while the power switch is shut off.

FIGURE 8

FIGURE 9

FIGURE 10

10 | FIGURE 11 |