The cutting speed should always exceed 40 m/s to lessen risk of kickback but should not exceed 70 m/s to lessen the risk of tool damage.

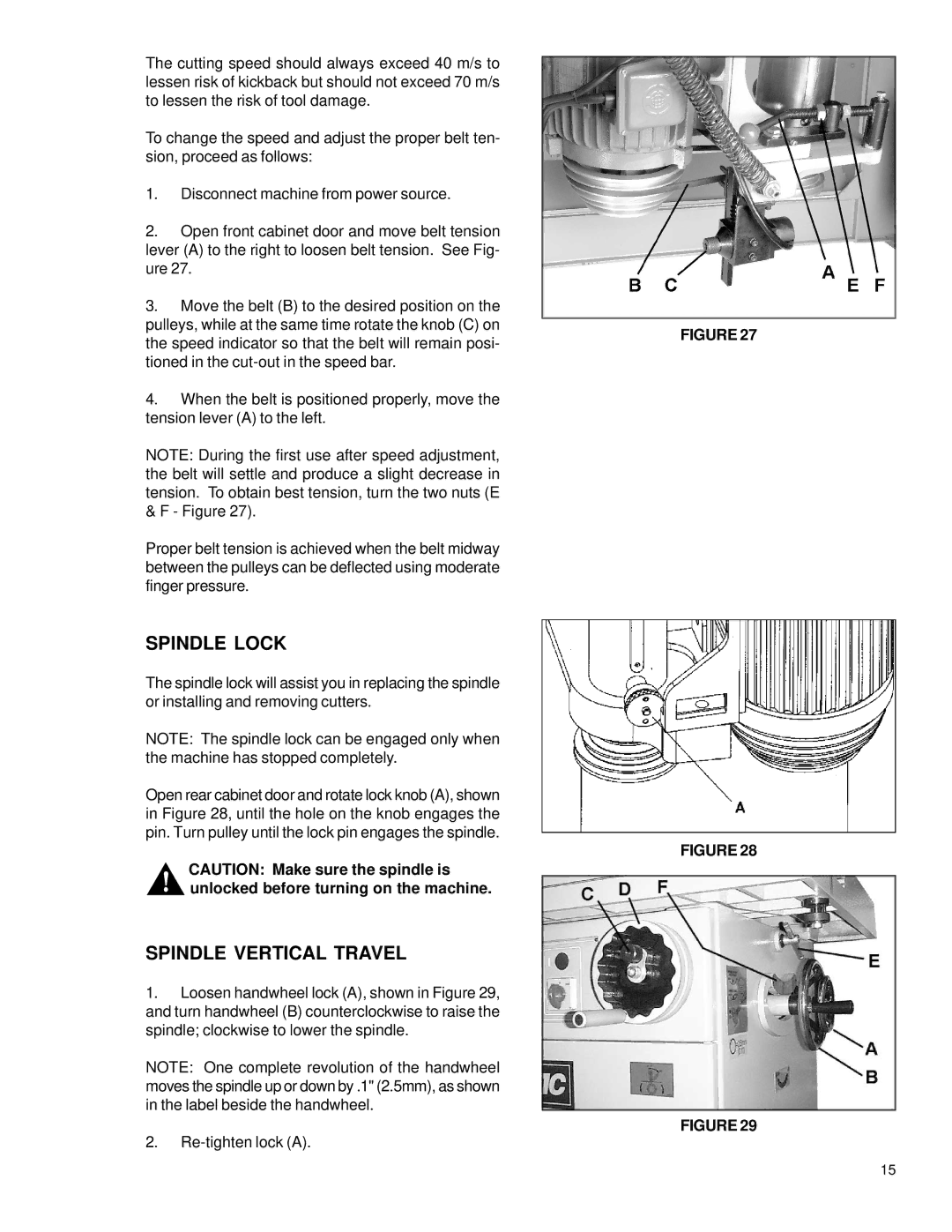

To change the speed and adjust the proper belt ten- sion, proceed as follows:

1.Disconnect machine from power source.

2.Open front cabinet door and move belt tension lever (A) to the right to loosen belt tension. See Fig- ure 27.

3.Move the belt (B) to the desired position on the pulleys, while at the same time rotate the knob (C) on the speed indicator so that the belt will remain posi- tioned in the

4.When the belt is positioned properly, move the tension lever (A) to the left.

NOTE: During the first use after speed adjustment, the belt will settle and produce a slight decrease in tension. To obtain best tension, turn the two nuts (E & F - Figure 27).

Proper belt tension is achieved when the belt midway between the pulleys can be deflected using moderate finger pressure.

SPINDLE LOCK

The spindle lock will assist you in replacing the spindle or installing and removing cutters.

NOTE: The spindle lock can be engaged only when the machine has stopped completely.

Open rear cabinet door and rotate lock knob (A), shown in Figure 28, until the hole on the knob engages the pin. Turn pulley until the lock pin engages the spindle.

CAUTION: Make sure the spindle is

! unlocked before turning on the machine.

SPINDLE VERTICAL TRAVEL

1.Loosen handwheel lock (A), shown in Figure 29, and turn handwheel (B) counterclockwise to raise the spindle; clockwise to lower the spindle.

NOTE: One complete revolution of the handwheel moves the spindle up or down by .1" (2.5mm), as shown in the label beside the handwheel.

2.

FIGURE 27

FIGURE 28

FIGURE 29

15