4.Disengage spindle lock before operating.

NOTE: Whenever possible, the cutter should be posi- tioned on the spindle in such a way that the cut is being performed under the surface of the workpiece.

WARNING: Always place the "keyed"

!washer (C) on the spindle before threading the nut.

FENCE ASSEMBLY

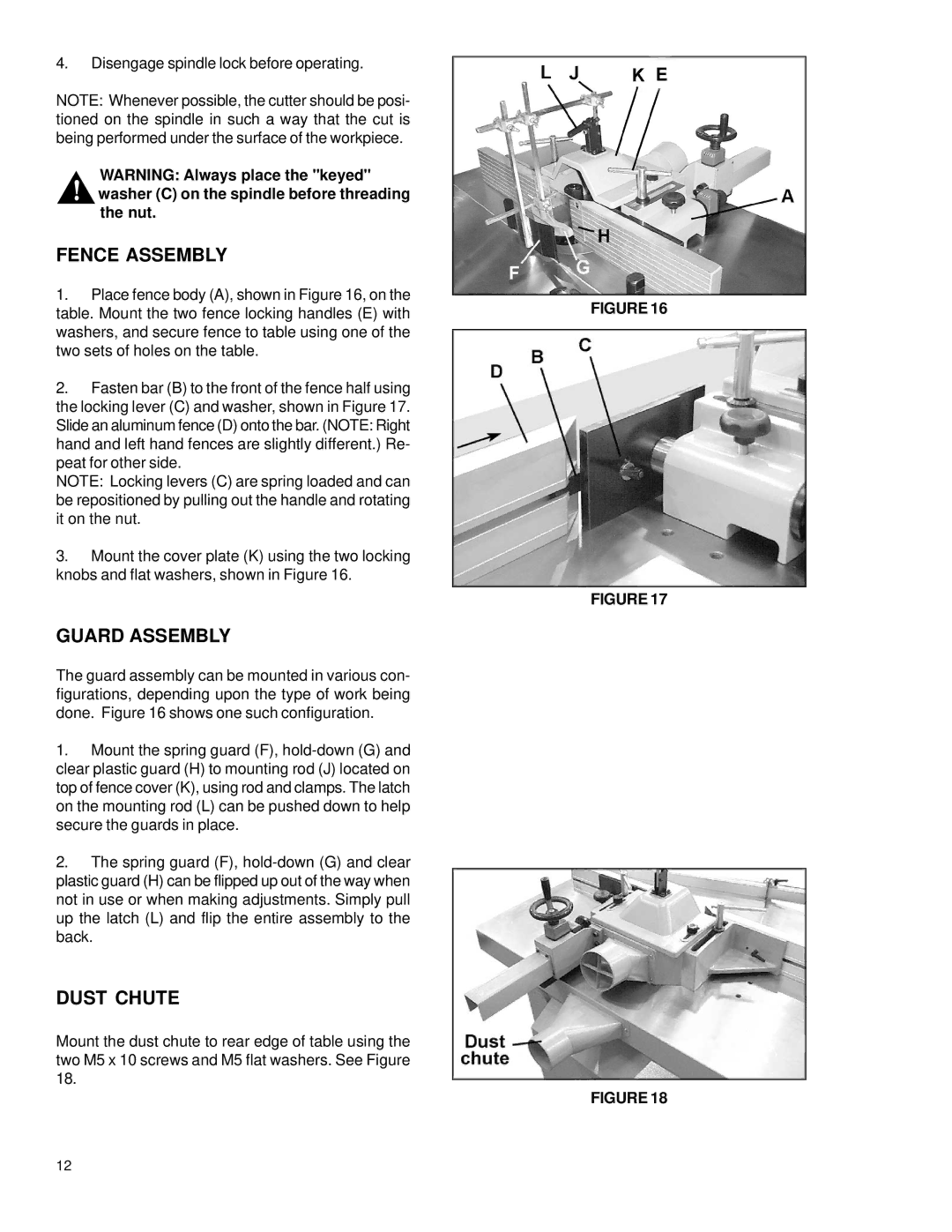

1.Place fence body (A), shown in Figure 16, on the table. Mount the two fence locking handles (E) with washers, and secure fence to table using one of the two sets of holes on the table.

2.Fasten bar (B) to the front of the fence half using the locking lever (C) and washer, shown in Figure 17. Slide an aluminum fence (D) onto the bar. (NOTE: Right hand and left hand fences are slightly different.) Re- peat for other side.

NOTE: Locking levers (C) are spring loaded and can be repositioned by pulling out the handle and rotating it on the nut.

3.Mount the cover plate (K) using the two locking knobs and flat washers, shown in Figure 16.

GUARD ASSEMBLY

The guard assembly can be mounted in various con- figurations, depending upon the type of work being done. Figure 16 shows one such configuration.

1.Mount the spring guard (F),

2.The spring guard (F),

DUST CHUTE

Mount the dust chute to rear edge of table using the two M5 x 10 screws and M5 flat washers. See Figure 18.

FIGURE 16

FIGURE 17

FIGURE 18

12