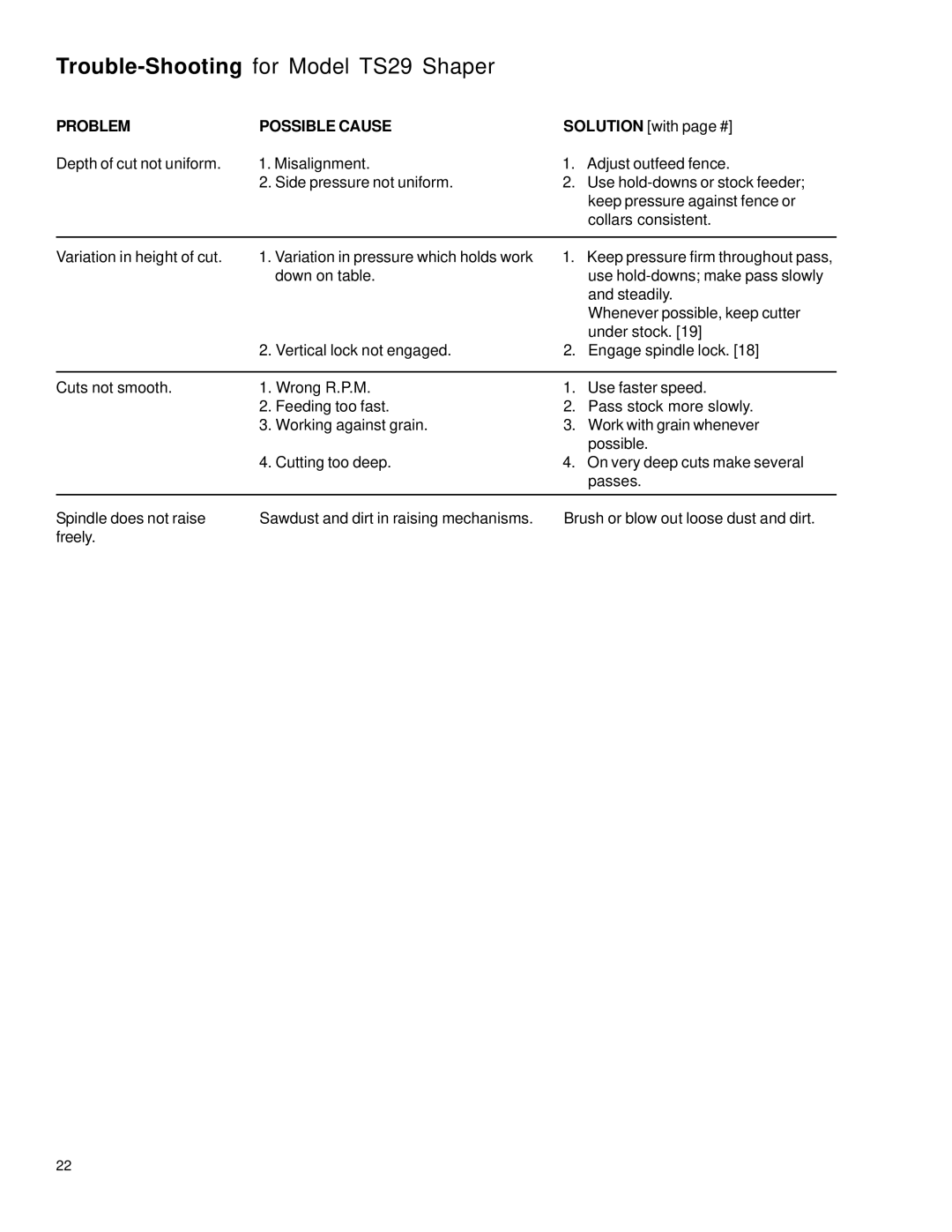

Trouble-Shooting for Model TS29 Shaper

PROBLEM | POSSIBLE CAUSE | SOLUTION [with page #] | |

Depth of cut not uniform. | 1. Misalignment. | 1. | Adjust outfeed fence. |

| 2. Side pressure not uniform. | 2. | Use |

|

|

| keep pressure against fence or |

|

|

| collars consistent. |

|

|

| |

Variation in height of cut. | 1. Variation in pressure which holds work | 1. Keep pressure firm throughout pass, | |

| down on table. |

| use |

|

|

| and steadily. |

|

|

| Whenever possible, keep cutter |

|

|

| under stock. [19] |

| 2. Vertical lock not engaged. | 2. | Engage spindle lock. [18] |

|

|

|

|

Cuts not smooth. | 1. Wrong R.P.M. | 1. | Use faster speed. |

| 2. Feeding too fast. | 2. | Pass stock more slowly. |

| 3. Working against grain. | 3. | Work with grain whenever |

|

|

| possible. |

| 4. Cutting too deep. | 4. | On very deep cuts make several |

|

|

| passes. |

|

|

| |

Spindle does not raise | Sawdust and dirt in raising mechanisms. | Brush or blow out loose dust and dirt. | |

freely. |

|

|

|

22