10 Troubleshooting

With proper installation, operation, and maintenance your gas appliance will provide years of

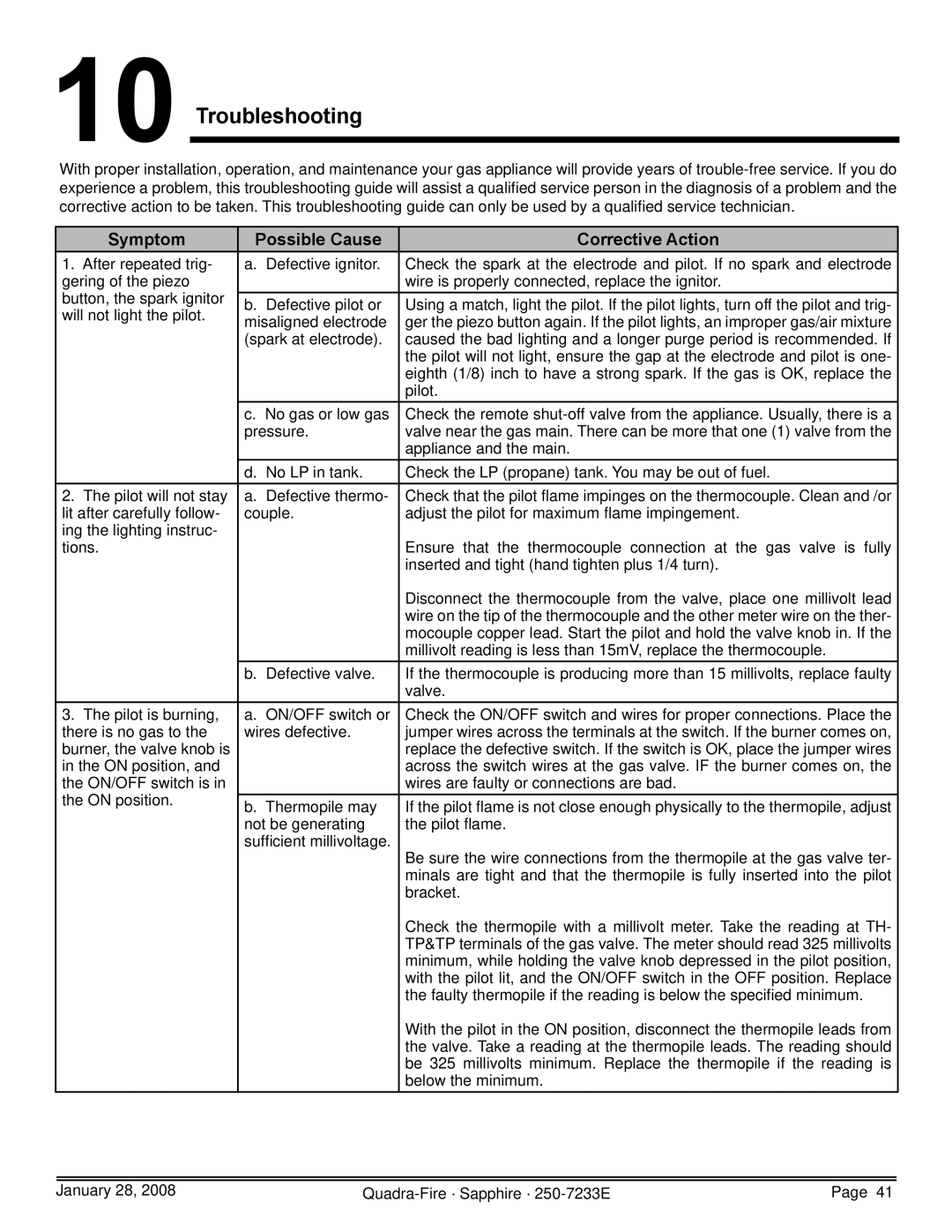

Symptom | Possible Cause | Corrective Action | |

1. After repeated trig- | a. Defective ignitor. | Check the spark at the electrode and pilot. If no spark and electrode | |

gering of the piezo |

| wire is properly connected, replace the ignitor. | |

button, the spark ignitor |

|

| |

b. Defective pilot or | Using a match, light the pilot. If the pilot lights, turn off the pilot and trig- | ||

will not light the pilot. | |||

misaligned electrode | ger the piezo button again. If the pilot lights, an improper gas/air mixture | ||

| |||

| (spark at electrode). | caused the bad lighting and a longer purge period is recommended. If | |

|

| the pilot will not light, ensure the gap at the electrode and pilot is one- | |

|

| eighth (1/8) inch to have a strong spark. If the gas is OK, replace the | |

|

| pilot. | |

| c. No gas or low gas | Check the remote | |

| pressure. | valve near the gas main. There can be more that one (1) valve from the | |

|

| appliance and the main. | |

| d. No LP in tank. | Check the LP (propane) tank. You may be out of fuel. | |

2. The pilot will not stay | a. Defective thermo- | Check that the pilot flame impinges on the thermocouple. Clean and /or | |

lit after carefully follow- | couple. | adjust the pilot for maximum flame impingement. | |

ing the lighting instruc- |

|

| |

tions. |

| Ensure that the thermocouple connection at the gas valve is fully | |

|

| inserted and tight (hand tighten plus 1/4 turn). | |

|

| Disconnect the thermocouple from the valve, place one millivolt lead | |

|

| wire on the tip of the thermocouple and the other meter wire on the ther- | |

|

| mocouple copper lead. Start the pilot and hold the valve knob in. If the | |

|

| millivolt reading is less than 15mV, replace the thermocouple. | |

| b. Defective valve. | If the thermocouple is producing more than 15 millivolts, replace faulty | |

|

| valve. | |

3. The pilot is burning, | a. ON/OFF switch or | Check the ON/OFF switch and wires for proper connections. Place the | |

there is no gas to the | wires defective. | jumper wires across the terminals at the switch. If the burner comes on, | |

burner, the valve knob is |

| replace the defective switch. If the switch is OK, place the jumper wires | |

in the ON position, and |

| across the switch wires at the gas valve. IF the burner comes on, the | |

the ON/OFF switch is in |

| wires are faulty or connections are bad. | |

the ON position. |

|

| |

b. Thermopile may | If the pilot flame is not close enough physically to the thermopile, adjust | ||

| not be generating | the pilot flame. | |

| sufficient millivoltage. | Be sure the wire connections from the thermopile at the gas valve ter- | |

|

| ||

|

| minals are tight and that the thermopile is fully inserted into the pilot | |

|

| bracket. | |

|

| Check the thermopile with a millivolt meter. Take the reading at TH- | |

|

| TP&TP terminals of the gas valve. The meter should read 325 millivolts | |

|

| minimum, while holding the valve knob depressed in the pilot position, | |

|

| with the pilot lit, and the ON/OFF switch in the OFF position. Replace | |

|

| the faulty thermopile if the reading is below the specified minimum. | |

|

| With the pilot in the ON position, disconnect the thermopile leads from | |

|

| the valve. Take a reading at the thermopile leads. The reading should | |

|

| be 325 millivolts minimum. Replace the thermopile if the reading is | |

|

| below the minimum. |

January 28, 2008 | Page 41 |