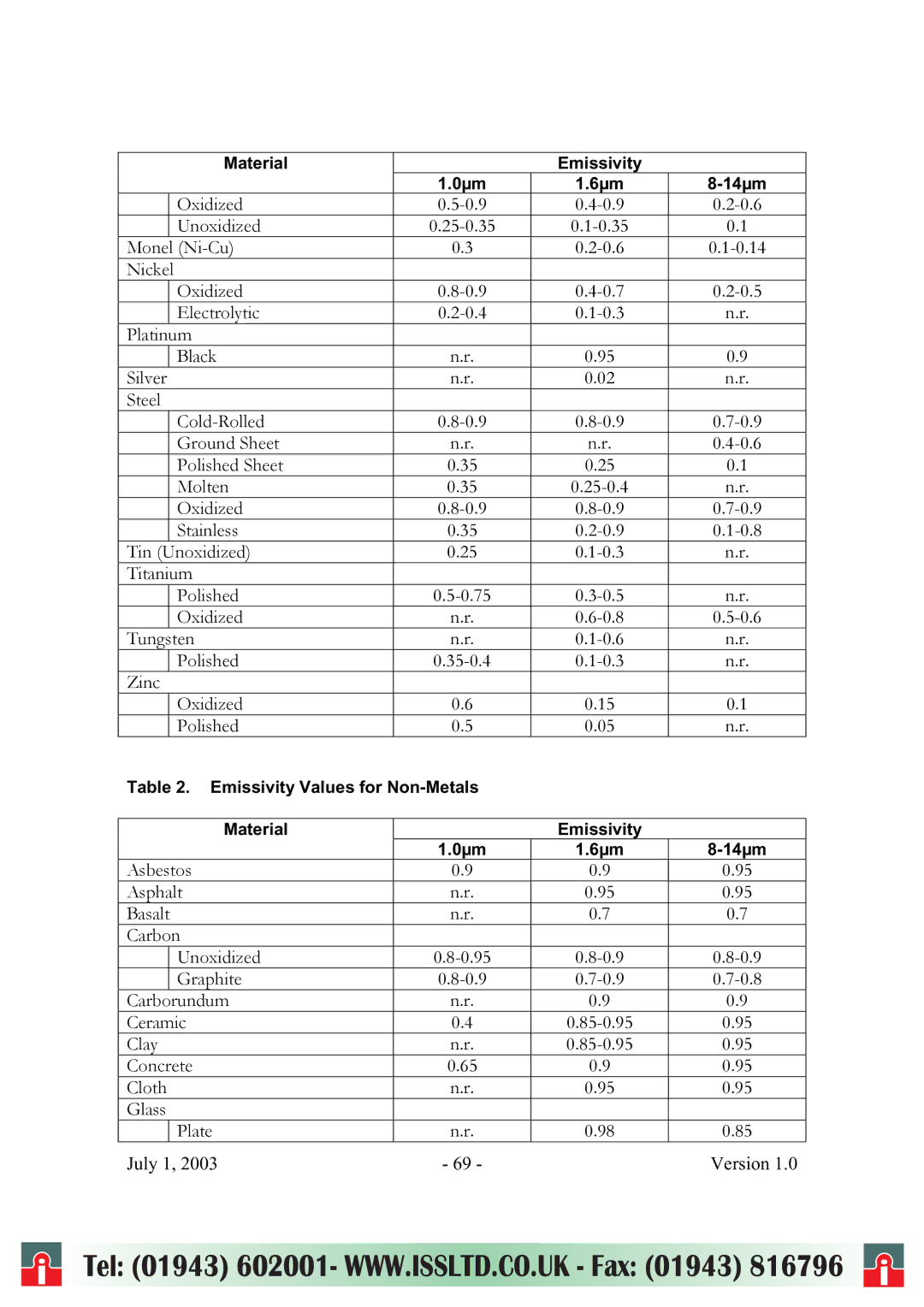

| Material |

| Emissivity |

|

|

| 1.0µm | 1.6µm | |

| Oxidized | |||

| Unoxidized | 0.1 | ||

Monel |

| 0.3 | ||

Nickel |

|

|

| |

| Oxidized | |||

| Electrolytic | n.r. | ||

Platinum |

|

|

| |

| Black | n.r. | 0.95 | 0.9 |

Silver |

| n.r. | 0.02 | n.r. |

Steel |

|

|

| |

| ||||

| Ground Sheet | n.r. | n.r. | |

| Polished Sheet | 0.35 | 0.25 | 0.1 |

| Molten | 0.35 | n.r. | |

| Oxidized | |||

| Stainless | 0.35 | ||

Tin | (Unoxidized) | 0.25 | n.r. | |

Titanium |

|

|

| |

| Polished | n.r. | ||

| Oxidized | n.r. | ||

Tungsten | n.r. | n.r. | ||

| Polished | n.r. | ||

Zinc |

|

|

|

|

| Oxidized | 0.6 | 0.15 | 0.1 |

| Polished | 0.5 | 0.05 | n.r. |

Table 2. Emissivity Values for |

|

| ||

|

|

|

|

|

| Material |

| Emissivity |

|

|

| 1.0µm | 1.6µm | |

Asbestos | 0.9 | 0.9 | 0.95 | |

Asphalt | n.r. | 0.95 | 0.95 | |

Basalt | n.r. | 0.7 | 0.7 | |

Carbon |

|

|

| |

| Unoxidized | |||

| Graphite | |||

Carborundum | n.r. | 0.9 | 0.9 | |

Ceramic | 0.4 | 0.95 | ||

Clay | n.r. | 0.95 | ||

Concrete | 0.65 | 0.9 | 0.95 | |

Cloth | n.r. | 0.95 | 0.95 | |

Glass |

|

|

| |

| Plate | n.r. | 0.98 | 0.85 |

July 1, 2003 | - 69 - |

| Version 1.0 | |

i | Tel: (01943) 602001- WWW.ISSLTD.CO.UK - Fax: (01943) 816796 | i |