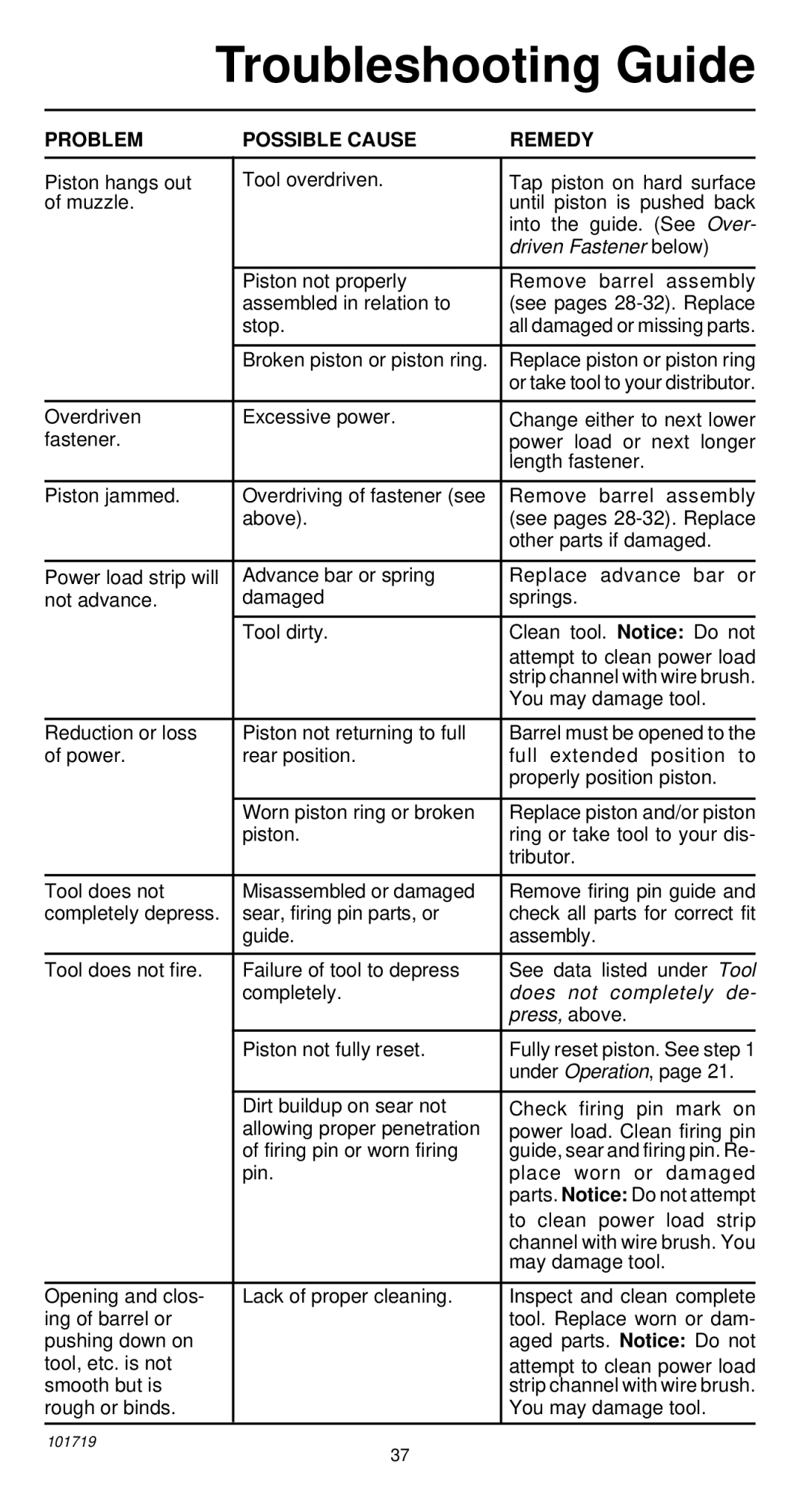

Troubleshooting Guide

PROBLEM | POSSIBLE CAUSE | REMEDY |

|

Piston hangs out | Tool overdriven. | Tap piston on hard surface | |

of muzzle. |

| until piston is pushed back | |

|

| into the guide. (See Over- | |

|

| driven Fastener below) | |

|

|

|

|

| Piston not properly | Remove barrel assembly |

|

| assembled in relation to | (see pages | |

| stop. | all damaged or missing parts. | |

|

|

|

|

| Broken piston or piston ring. | Replace piston or piston ring | |

|

| or take tool to your distributor. | |

|

|

| |

Overdriven | Excessive power. | Change either to next lower | |

fastener. |

| power load or next longer | |

|

| length fastener. | |

|

|

|

|

Piston jammed. | Overdriving of fastener (see | Remove barrel assembly | |

| above). | (see pages | |

|

| other parts if damaged. | |

|

|

|

|

Power load strip will | Advance bar or spring | Replace advance bar or | |

not advance. | damaged | springs. | |

|

|

|

|

| Tool dirty. | Clean tool. Notice: Do not | |

|

| attempt to clean power load | |

|

| strip channel with wire brush. | |

|

| You may damage tool. | |

|

|

|

|

Reduction or loss | Piston not returning to full | Barrel must be opened to the | |

of power. | rear position. | full extended position to | |

|

| properly position piston. | |

|

|

|

|

| Worn piston ring or broken | Replace piston and/or piston | |

| piston. | ring or take tool to your dis- | |

|

| tributor. | |

|

|

|

|

Tool does not | Misassembled or damaged | Remove firing pin guide and | |

completely depress. | sear, firing pin parts, or | check all parts for correct fit | |

| guide. | assembly. | |

|

|

|

|

Tool does not fire. | Failure of tool to depress | See data listed under Tool | |

| completely. | does not completely de- | |

|

| press, above. | |

|

|

|

|

| Piston not fully reset. | Fully reset piston. See step 1 | |

|

| under Operation, page 21. | |

|

|

|

|

| Dirt buildup on sear not | Check firing pin mark on | |

| allowing proper penetration | power load. Clean firing pin | |

| of firing pin or worn firing | guide, sear and firing pin. Re- | |

| pin. | place worn or damaged | |

|

| parts. Notice: Do not attempt | |

|

| to clean power load strip | |

|

| channel with wire brush. You | |

|

| may damage tool. | |

|

|

|

|

Opening and clos- | Lack of proper cleaning. | Inspect and clean complete | |

ing of barrel or |

| tool. Replace worn or dam- | |

pushing down on |

| aged parts. Notice: Do not | |

tool, etc. is not |

| attempt to clean power load | |

smooth but is |

| strip channel with wire brush. | |

rough or binds. |

| You may damage tool. | |

|

|

|

|

101719 |

|

|

|

37